Installation

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09)24

▶ All horizontal flue sections must rise by at least 52mm for each metre

(3°) away from the boiler to ensure that condensate flows back into

the boiler for safe discharge via the condensate waste pipe.

▶ The horizontal terminal must be installed at 3° to ensure that the

condensate drains back to the boiler whilst also preventing rain

ingress down the air duct.

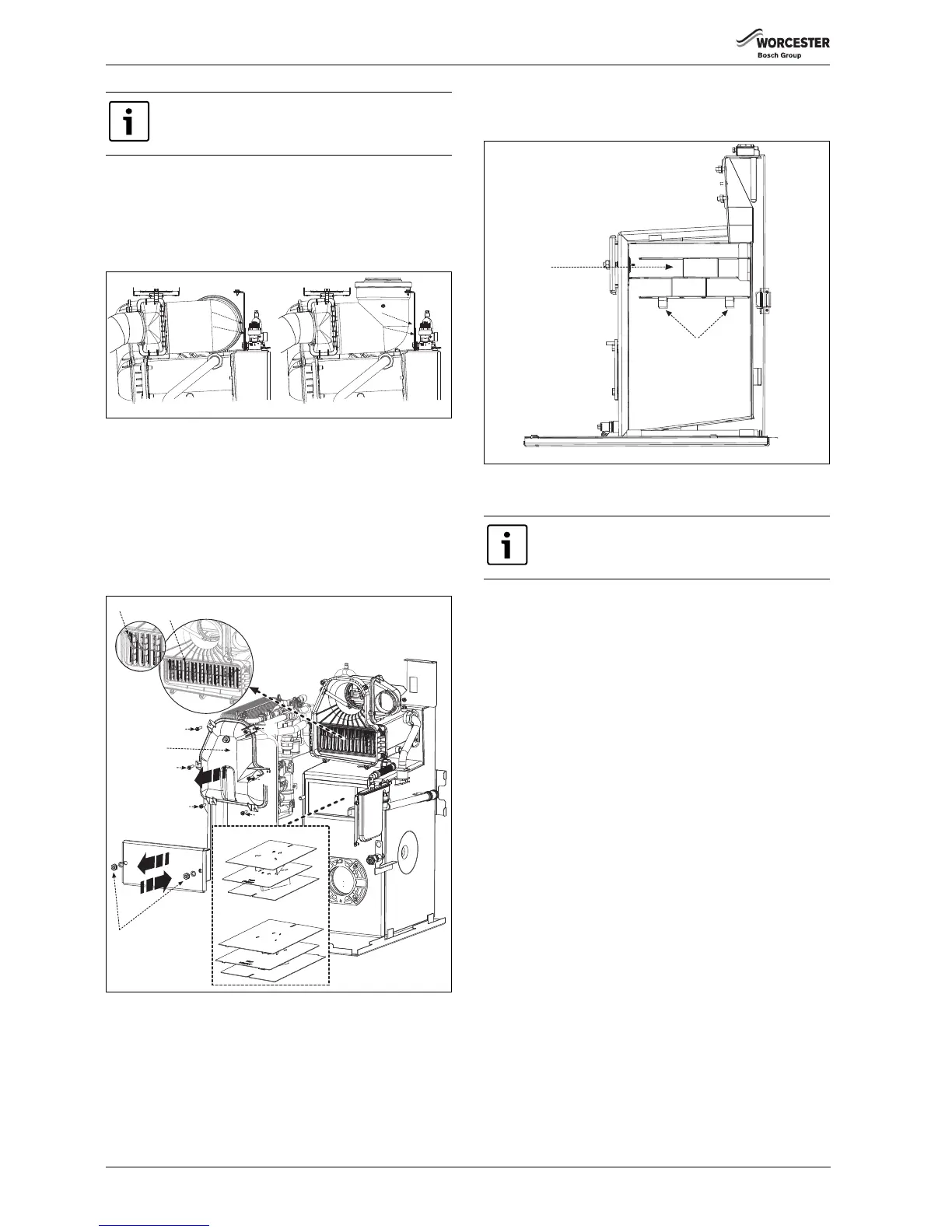

Fig. 31

▶ The retaining bracket [M] must be fitted if a flue elbow is used on the

boiler flue outlet.

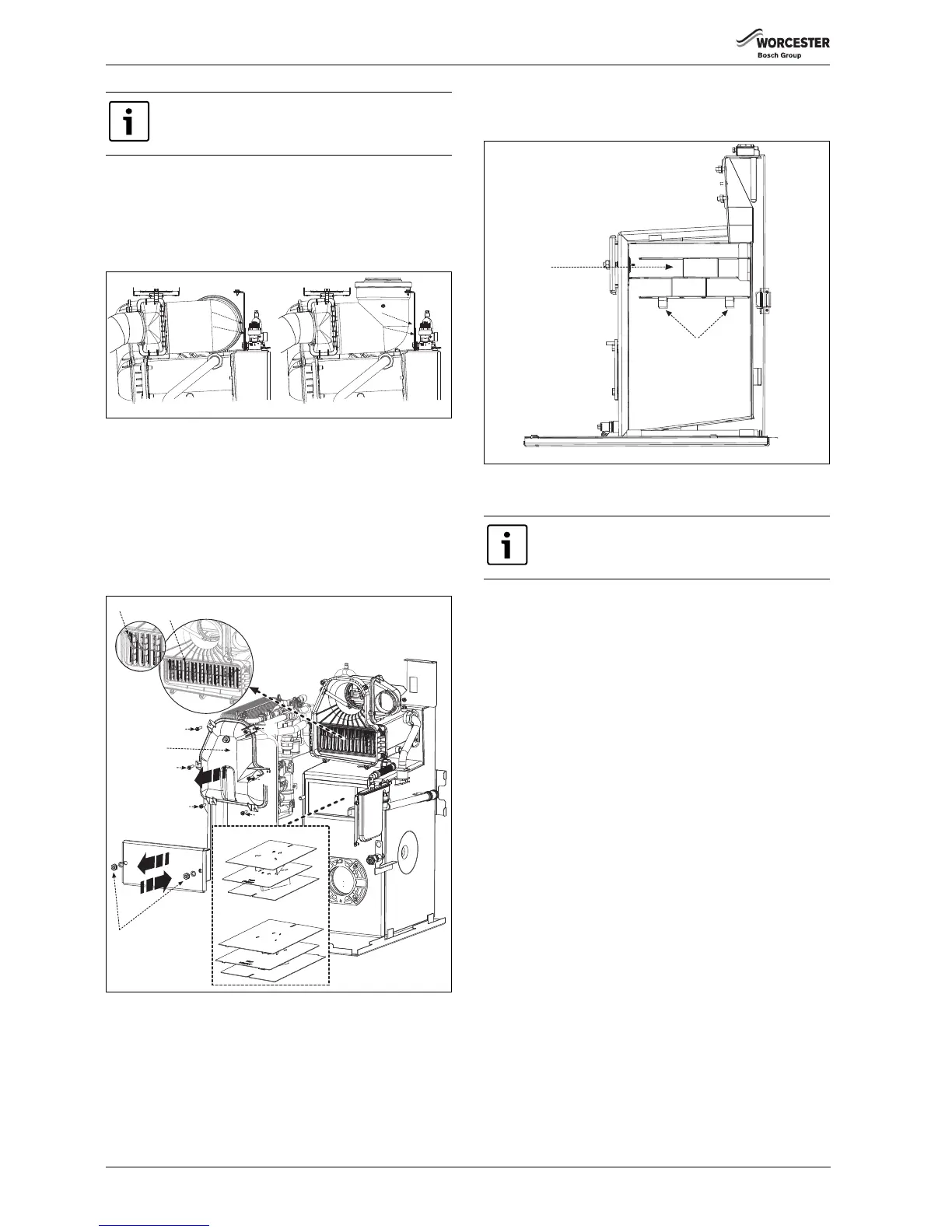

5.5 Combustion chamber

▶ Unscrew screws [G] and remove flue manifold access cover [H].

▶ Check that all the baffles [J] and baffle retainer [K] are correctly

fitted to the secondary heat exchanger.

▶ Remove the retaining nuts and washers [B].

▶ Remove combustion chamber/baffle access door [A].

Fig. 32

▶ Ensure one piece baffle set [C] is in the right location [D], correctly

resting on the baffle rests [F] on either side of the combustion

chamber and pushed securely into place.

Fig. 33

▶ Refit combustion chamber door [A].

The boiler is not designed to take the weight of the flue

system, this must be supported externally to the boiler.

Bracket (M)

Screw (N)

Bracket (M)

Screw (N)

6 720 805 209-10.1TL

Loading...

Loading...