Commissioning

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09) 37

6.4 Water treatment

Ensure that the system has been cleaned. Refer to section 4.1.2 of

these instructions.

Flushing (Central Heating)

▶ Ensure the appliance is switched off.

▶ Open all drain cocks and drain the system while the appliance is hot.

▶ Close drain cocks and add a suitable flushing agent at the correct

strength for the system condition in accordance with the

manufacturer's instructions.

▶ Run the appliance/system at normal operating temperature for the

time stated by the manufacturer of the flushing agent.

▶ Drain and thoroughly flush the system to remove the flushing agent

and debris.

Inhibitor (Central Heating)

▶ Check drain cocks are closed and all radiator valves are open before

adding a suitable inhibitor compatible with aluminium (or combined

inhibitor/anti-freeze if the system is exposed to freezing conditions)

to the heating system water in accordance with the manufacturers

instructions.

▶ Fill system via a WRAS approved filling loop to between 1 and 1.5

bar.

▶ Vent all radiators; tighten vents when complete.

▶ Re-pressurise, if necessary, to approximately 1bar.

▶ Set all controls to maximum.

▶ Record the date when the inhibitor was added to the system in the

Boiler commissioning checklist and in the guarantee registration.

Water treatment products

Suitable water treatment products can be obtain from the following

manufacturers:

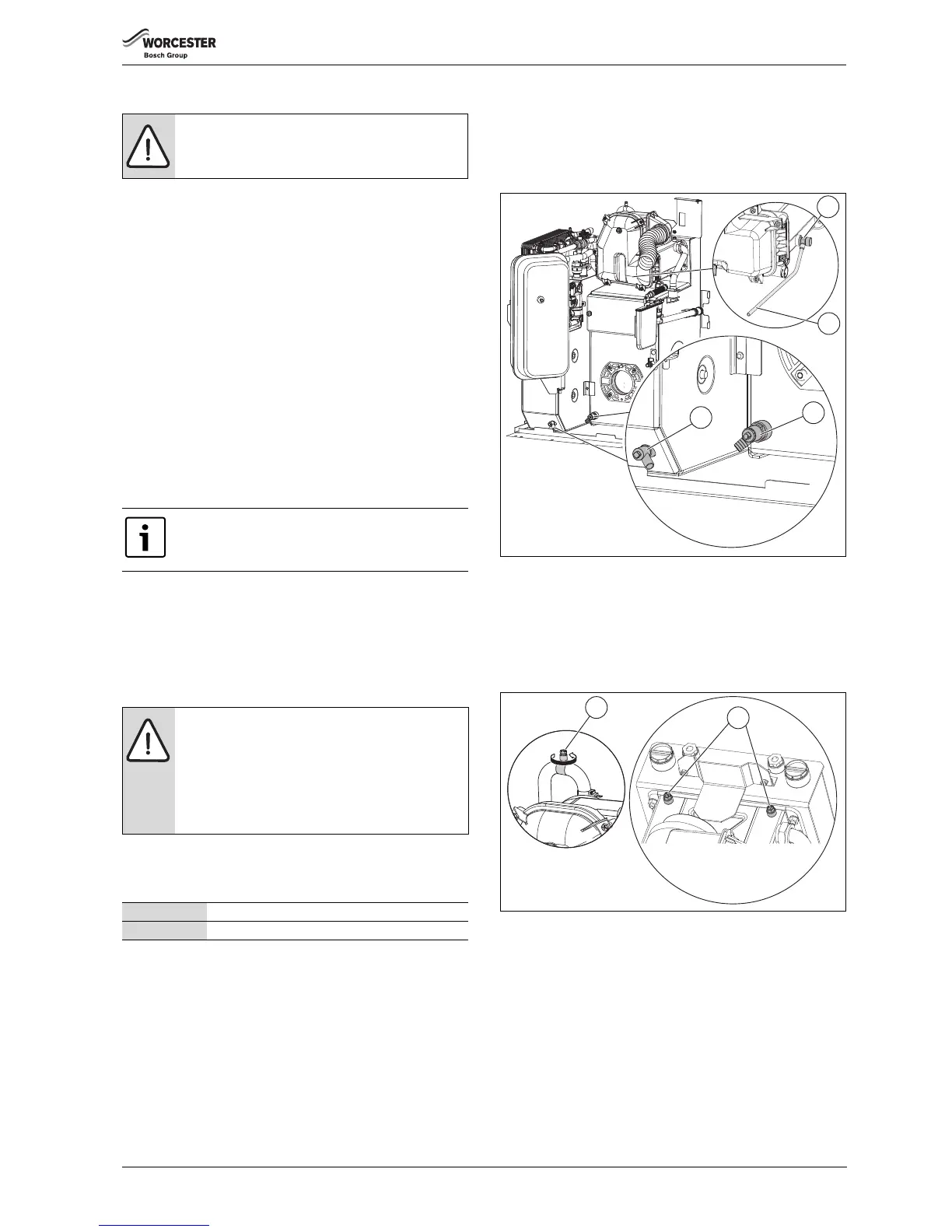

Appliance Drain Points

▶ The appliance can be drained via the primary heat exchanger point

[4]:

– There is an additional drain point on the secondary heat

exchanger [1] with drain tube [2].

– The heat bank also has a drain point [3]

Fig. 69 Appliance drains points

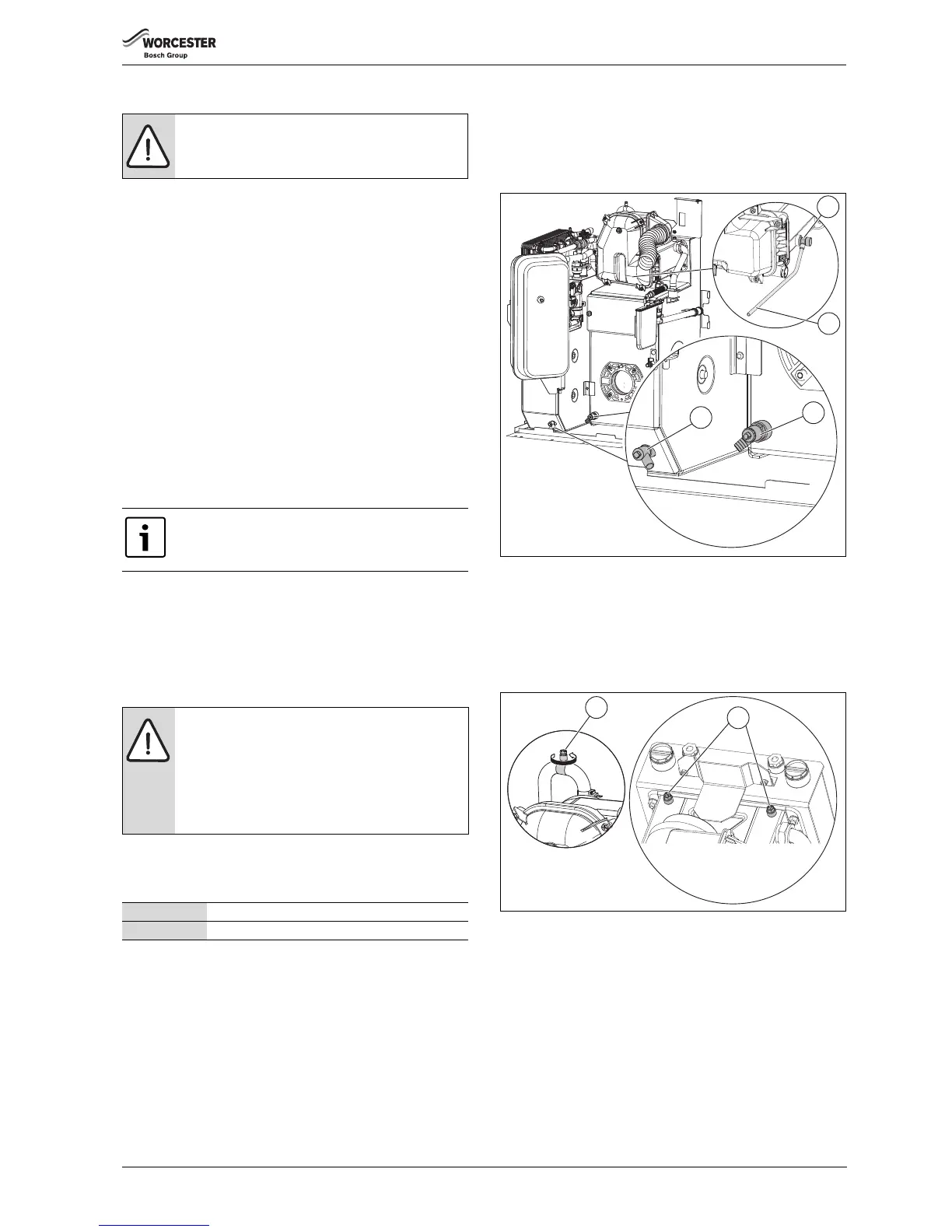

Appliance manual vent points

▶ The appliance can be manually vented via:

– The two vent points at the top of the secondary heat exchanger.

Only one may be in use, the other may be obscured by side fluing.

– A vent point on the primary flow from the primary heat exchanger.

▶ Use a radiator key or suitable screwdriver to open the vent point.

Fig. 70 Appliance manual vent points

6.5 Finishing commissioning - Appliance

1. Rotate the control box [A] towards you [B].

Slide back into position [C].

2. Locate the bottom edge of the front panel [D] onto the supporting

ledge off the baseplate [E] and secure in place with screws [F].

3. Locate the top panel [G] onto the brackets at the rear of the boiler

[H] and locate the ball stud connections [J] and press down to

secure.

Always apply pressure at the edges of the boiler panels when

securing to avoid accidental damage.

NOTICE:

▶ Artificially softened water must not be used to fill the

central heating system.

The pH value of the system water must be less than 8 or

the appliance warrantee will be invalidated.

NOTICE:

▶ The concentration of inhibitor in the system should

be checked every 12 months or sooner if system

content is lost.

▶ In cases where all attempts to find a micro leak have

failed, Worcester, Bosch Group supports the use of

Fernox F4 leak sealer.

FERNOX 0870 601 5000 or www.fernox.com

SENTINEL 0800 389 4670 or www.sentinel-solutions.net

Loading...

Loading...