Pre-Installation

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09) 19

4.9 Flue options

4.9.1 Conventional flue (CF)

• Open (conventional) flued appliances must not be installed in a

bedroom, bathroom or bed-sitting room.

• The flue system must be in accordance with BS 5410: Part 1 and the

current Building Regulations.

• The flue must be constructed of materials suitable for use with

condensing combustion products.

• External flue systems must be of the insulated type.

• Brick and masonry chimneys must be lined with a suitable non -

combustible material and properly jointed to withstand the effects of

the working temperature (minimum rating of material 120°C) of the

appliance and any condensate which may form.

• All flue joints must be sealed to prevent the leakage of condensate

and combustion products.

• Ensure that joints are made so that the condensate runs away and is

not collected within the joint.

CF Sizing

• Because the flue operates at a lower temperature on a condensing

boiler compared to that of a conventional appliance, the flue draught

will be lower.

Typically the draught will be between 0.5mmwg and 4.4mmwg,

measured with the flue warm but the burner not firing. The actual

figure will vary depending on weather conditions, flue height and

position.

• The flue should be vertical and contain as few bends as possible, a

maximum of two 135° bends should be used.

• The flue outlet must be extended beyond the eaves of the building

and where possible, above the apex.

• Fit a suitable anti down-draught terminal where down draughts are

experienced.

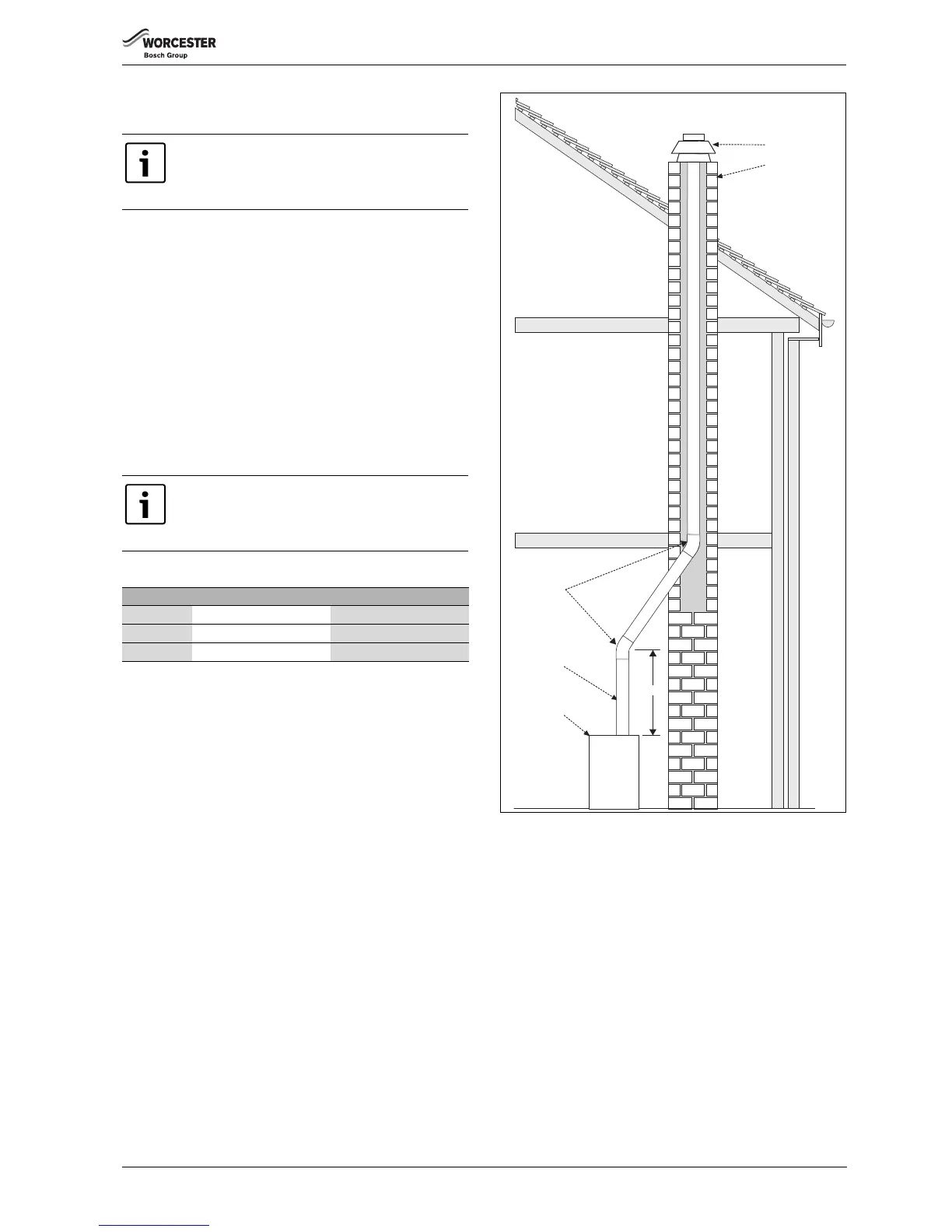

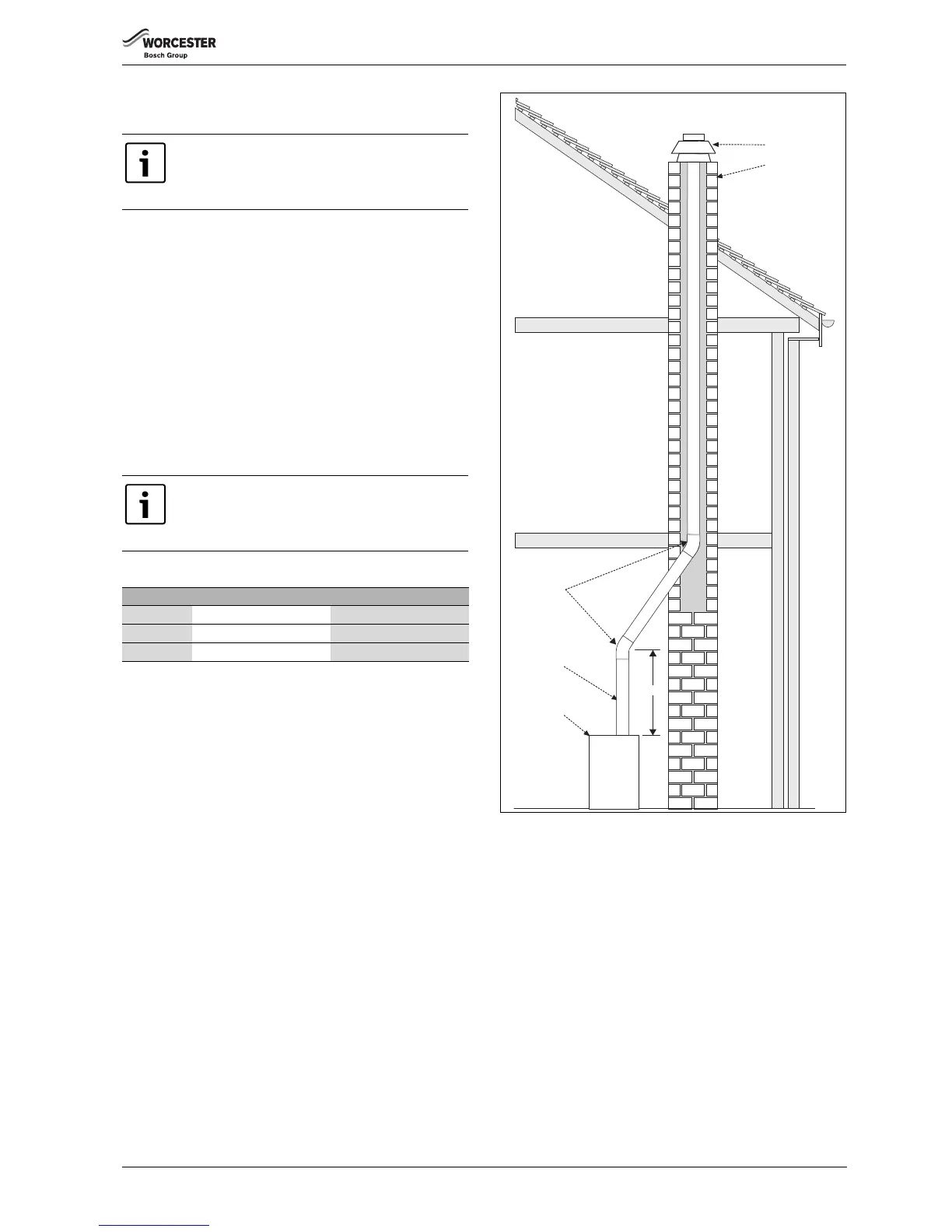

Fig. 23 Conventional flue

[A] Boiler

[B] Stainless steel flue

[C] Max. two bends at 135°

[D] Anti down-draught terminal

[E] Chimney

[F] Height to first bend from top of boiler (min. 600mm)

If an open-flued appliance is to be installed, a carbon

monoxide detector alarm conforming to BS EN 50291

must be fitted in accordance with manufacturer’s

instructions.

The flue can be increased in size from the boiler take off

point providing the joint is correctly sealed.

Never reduce the flue diameter from the boiler take off

point.

Boiler size Third party flue size Worcester Flexible Flue

12/18 100/103mm Ø 100mmØ

18/25 100/103mm Ø 100mmØ

25/32 130mm Ø 100mmØ

Loading...

Loading...