Fault finding and diagnosis

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09) 49

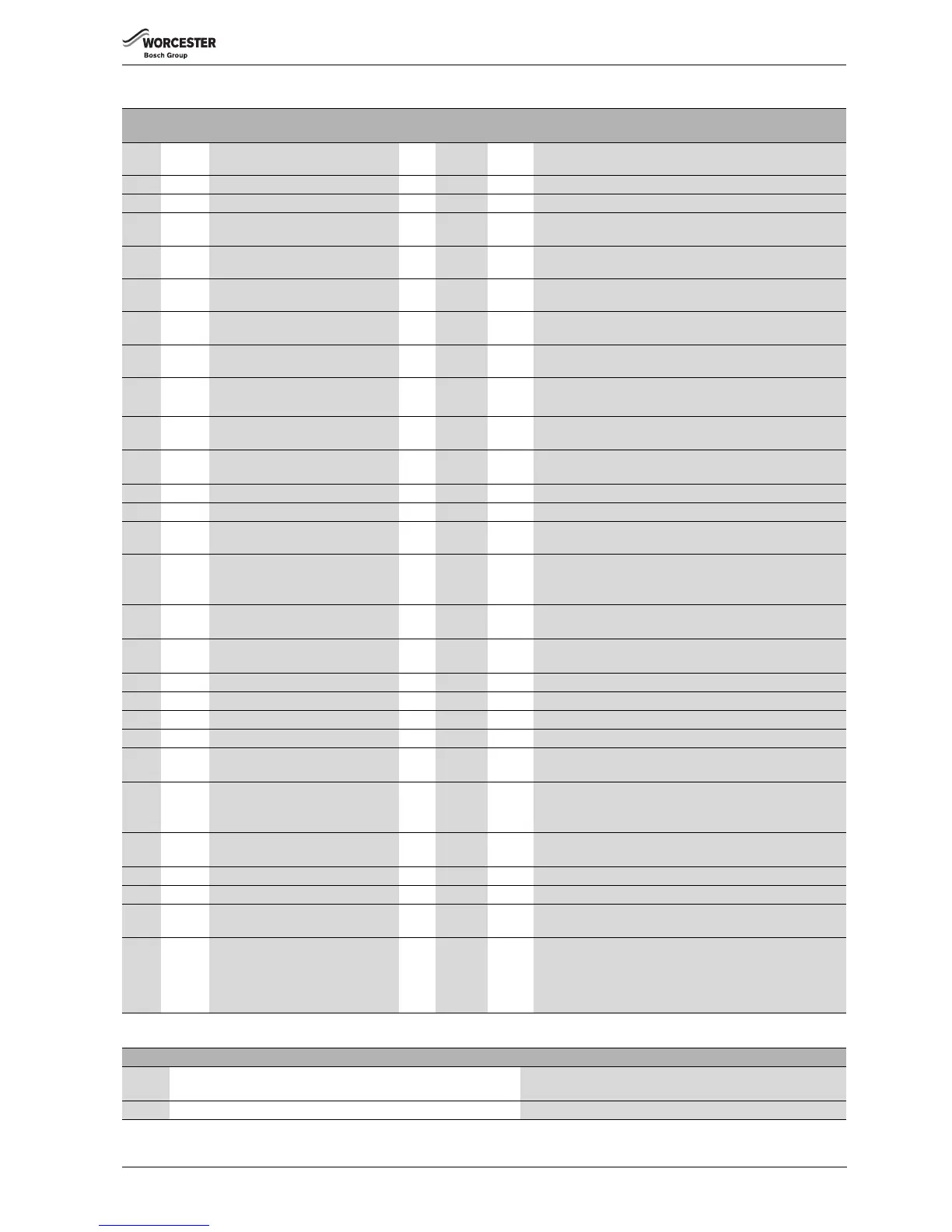

8.4.3 Cause and fault codes

Cause

code

Fault

code Description

Reset

type Blocking Locking Possible cause/solution

210 E9 Maximum temperature thermostat

activated

Reset

X

Flue gas or tank thermostat overheat. Reset the overheat

thermostat before resetting the appliance.

212 No code Safety or flow temperature too high X Air lock or reduced water content.

218 E5 Flow temperature too high Reset X Primary sensor overheated, wait 30 minutes and try a reset.

219 E9 Safety temperature too high Reset X The main heat exchanger has overheated.

Maximum temperature 105°C, wait 30 minutes and try a reset.

220 E9 Safety sensor short circuit Reset X Maximum temperature sensor on the main heat exchanger has

failed.

221 E9 Safety sensor open circuit Reset X Maximum temperature sensor on the main heat exchanger has

not been recognised.

222 E2 Flow sensor short circuit Reset X Flow sensor shorted or damaged, reconnect or replace as

required.

223 E2 Flow sensor open circuit Reset X Flow sensor disconnected or damaged, reconnect or replace as

required.

233 E2 HCM (Heat Control Module) Reset X HCM Code plug missing or defective.

Refer to table 14, i22 and i23 to determine HCM number fitted

237 F0 Software relay error Reset X Resistors between plug X4 pins 3 & 5 disconnected/>150k

or water in the burner control box

238 F0 Software relay error Reset X Resistors between plug X4 pins 3 & 5 disconnected/>150k

or water in the burner control box

239 F0 Watchdog relay error Reset X If the error persists, change the control board

259 FO A/D reference relay error Reset X If the error persists, change the control board

263 F0 Appliance powered off with locking

fault present

Reset X Locking fault still present when powered off/on, press the reset

button to clear.

271 D4 Temperature difference between flow

and safety sensors exceeds limit

X The temperature of the primary flow and the safety sensor on

the main heat exchanger should be within 15°C of each other.

Check the flow sensor is seated properly on the flow pipe.

276 E9 Flow temperature exceeds 95°C X Primary overheat - boiler waits for temperature to reduce, wait

approximately 30 minutes and try a reset.

277 E9 Safety temperature exceeds 95°C X Main heat exchanger safety sensor overheat - boiler waits for

temperature to reduce, approximately 30 minutes.

278 F0 Sensor test error Reset X On power up, all safety sensors are checked. Check has failed.

279 F0 A/D converter error Reset X If the error persists, change the control board

290 F0 A/D converter reference error Reset X If the error persists, change the control board

332 E5 Primary flow has exceeded 105°C Reset X Primary sensor overheated.

359 No Code DHW outlet or storage tank exceeds

90°C

X Pump & burner are blocked until temperature drops to <89°C.

wait approximately 30 minutes for temperature to drop.

360 9A Incorrect HCM for boiler variant X Replace with the correct HCM.

Refer to table 14, i22 and i23 to determine HCM number fitted

and select correct HCM number from list

380 No code Inlet DCW temperature higher than

DHW outlet temperature

X The output is blocked until the inlet temperature drops below

the output temperature, wait for approximately 30 minutes.

808 A7 DHW sensor defective Reset X Check and replace defect sensor as necessary

809 A0 Thermal store sensor defective Reset X Check and replace defect sensor as necessary

855 9F Burner lock out Reset X Check the burner and fuel supply. Ensure the oil supply is free

of contaminants.

856 9F 5 burner lockouts repeated resets Turn

boiler

off/on

X After Five 855 burner lock outs in one demand period, cause

code 856 is displayed.

After boiler off/on cause code 263 will be displayed, press the

reset button to clear this fault. another 5 burner lock resets can

be attempted.

Table 15 Cause and fault codes

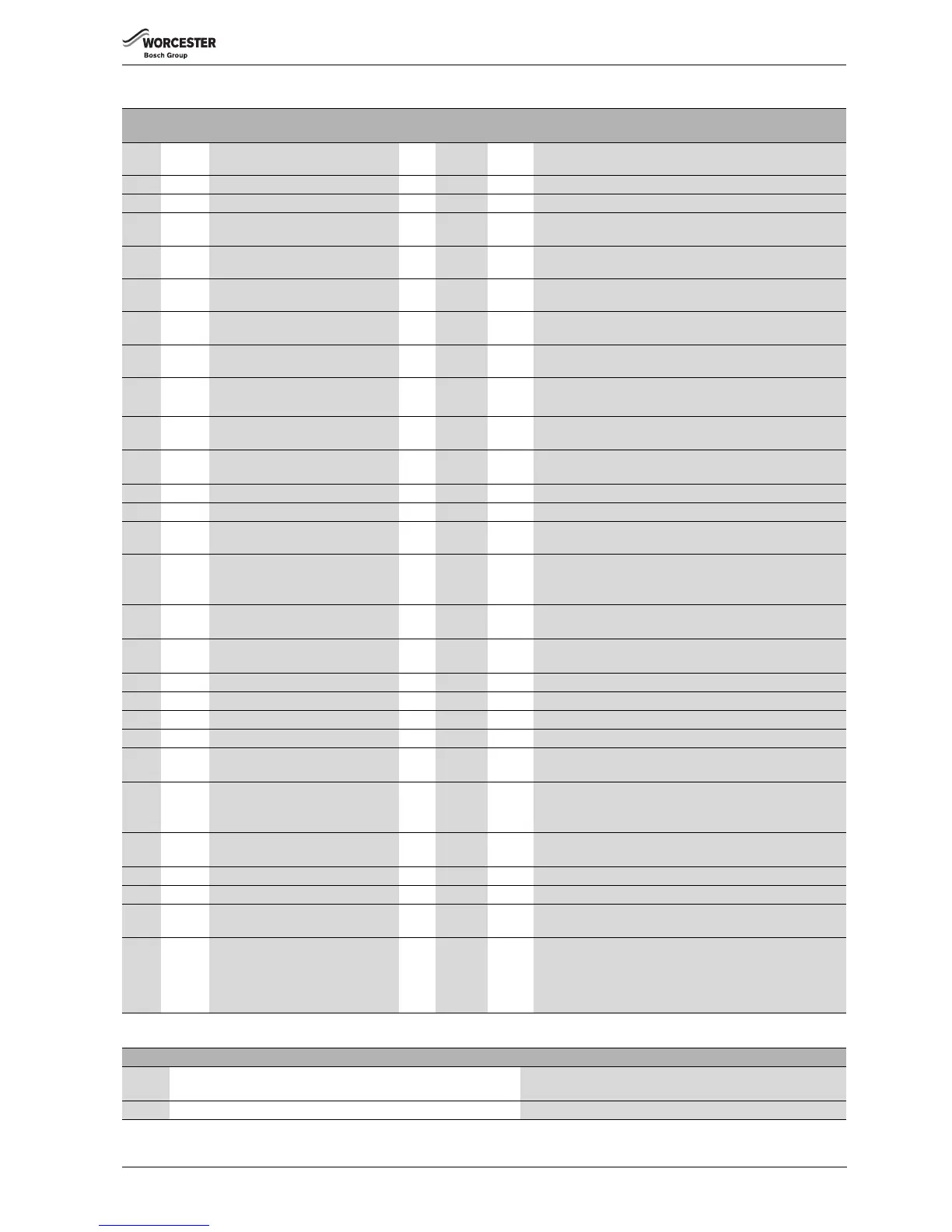

H code Displayed symbols Cause

H03 Warning triangle and House symbol displayed on controller Weather compensation activated but no weather sensor detected,

refer to section 5.11 on page 30 for more information.

H11 Warning triangle symbol displayed on controller DCW in sensor defect, (appliance operation not affected)

Table 16 H fault codes

Loading...

Loading...