Installation

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09)22

5.2 Pipework positions and flue opening

Safety

All relevant safety precautions must be undertaken. Protective clothing,

footwear, gloves and safety goggles must be worn as appropriate.

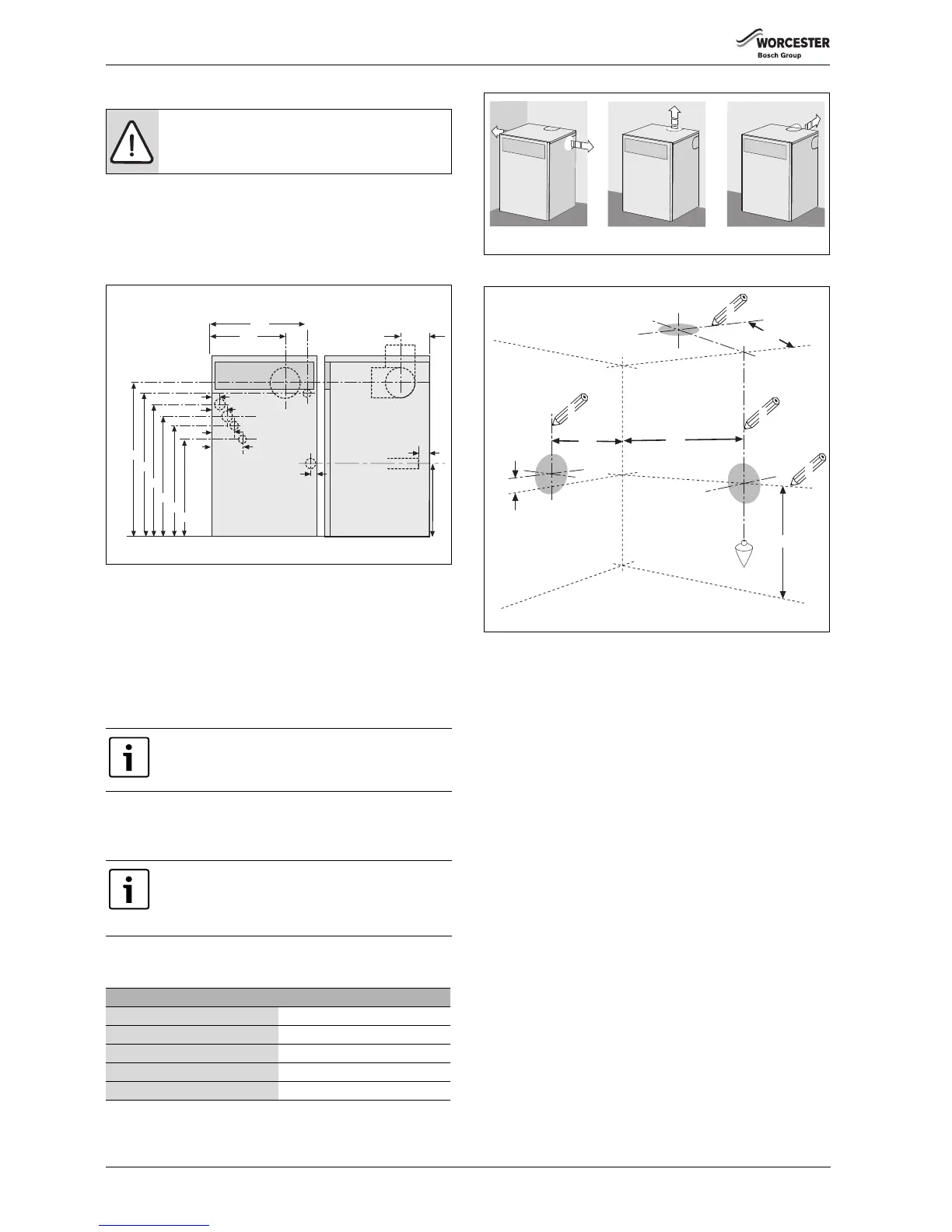

Pipework positions

A to G (below) show the flue and pipe positions:

Fig. 26

Pipework positions:

[A] CH flow 22mm Ø copper (28mm Ø on 25/32kW model)

[B] DHW flow 22mm Ø copper

[C] DCW mains water inlet 15mm Ø

[D] CH return 22mm Ø copper (28mm Ø on 25/32kW model)

[E] Flue outlet

[F] Pressure relief pipe 15mm Ø

[G] Condensate outlet 21.5mm Ø

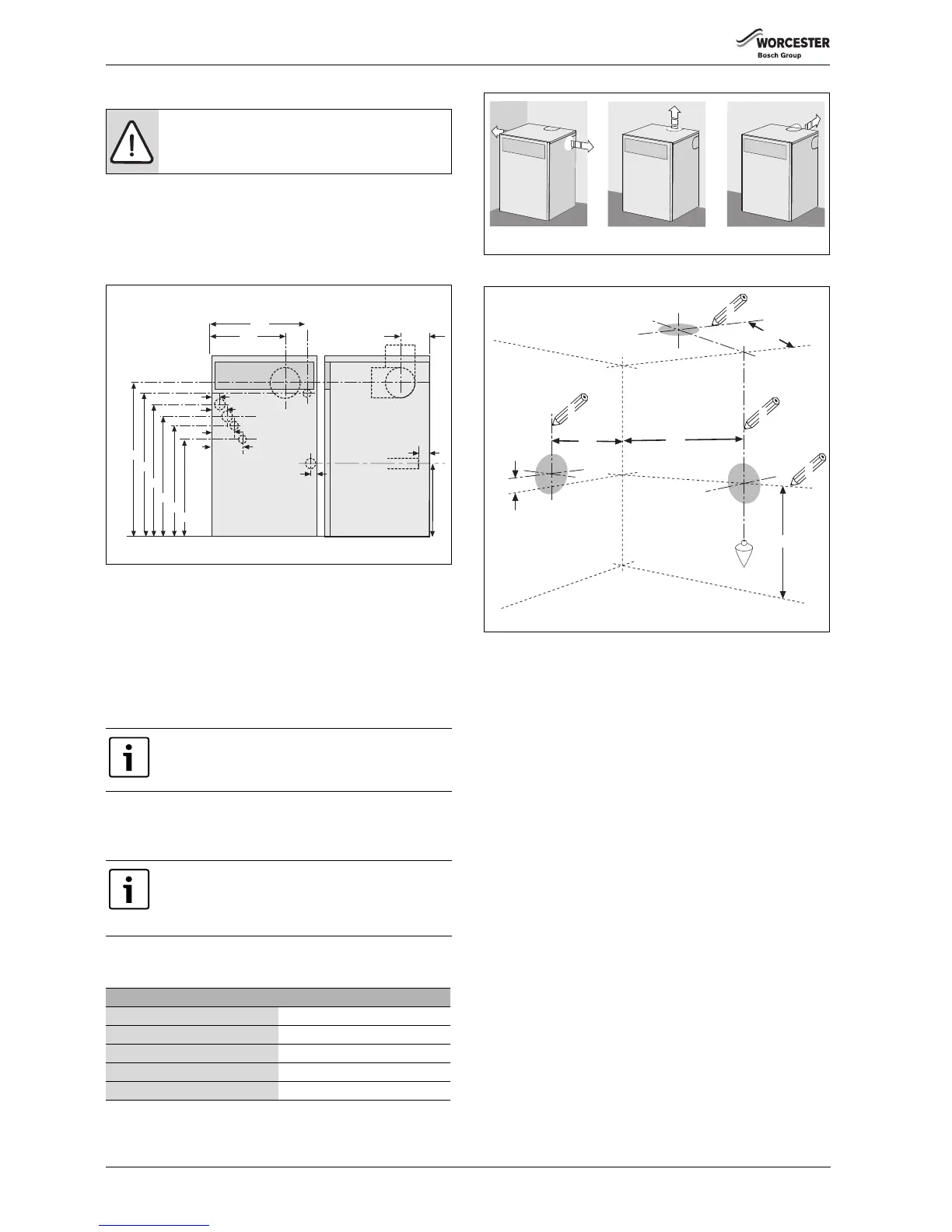

Flue opening

▶ Follow figure 28 to mark the centre of the flue (1, & 2) for rear

opening, (2 & 3) for side opening or (1 & 4) for top opening.

▶ Make an opening (X, Y or Z) through the wall using a core drill or

similar at a size relative to the wall thickness as shown below:

Fig. 27

Fig. 28

[**] IMPORTANT: for horizontal flues, increase this height by 5.2mm

for every 100mm of horizontal length that the flue opening is

away from the boiler.

CAUTION: Ensure there are no pipes, electric cables,

damp proof courses or other hazards before drilling.

For servicing purposes, keep the condensate and

pressure relief discharge pipes away from components

and pipework connections.

All horizontal flue sections must rise away from the boiler

by 52mm per metre to ensure that condensate flows

back into the boiler for safe discharge via the condensate

waste pipe.

125mm Ø flue

Wall thickness mm Flue hole size Ø mm

150 - 240 155

240 - 330 160

330 - 420 165

420 - 500 170

Table 6

Loading...

Loading...