Fault finding and diagnosis

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09) 51

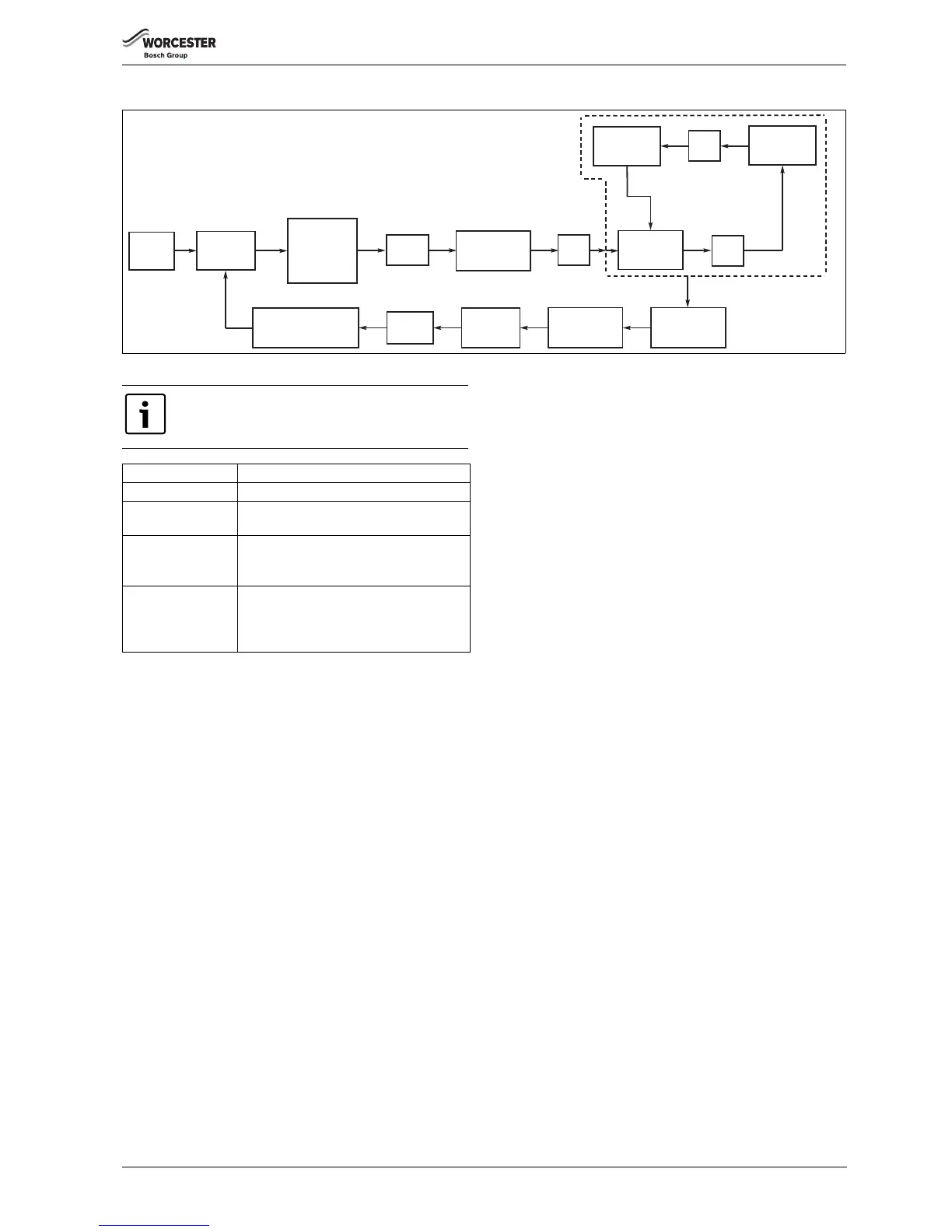

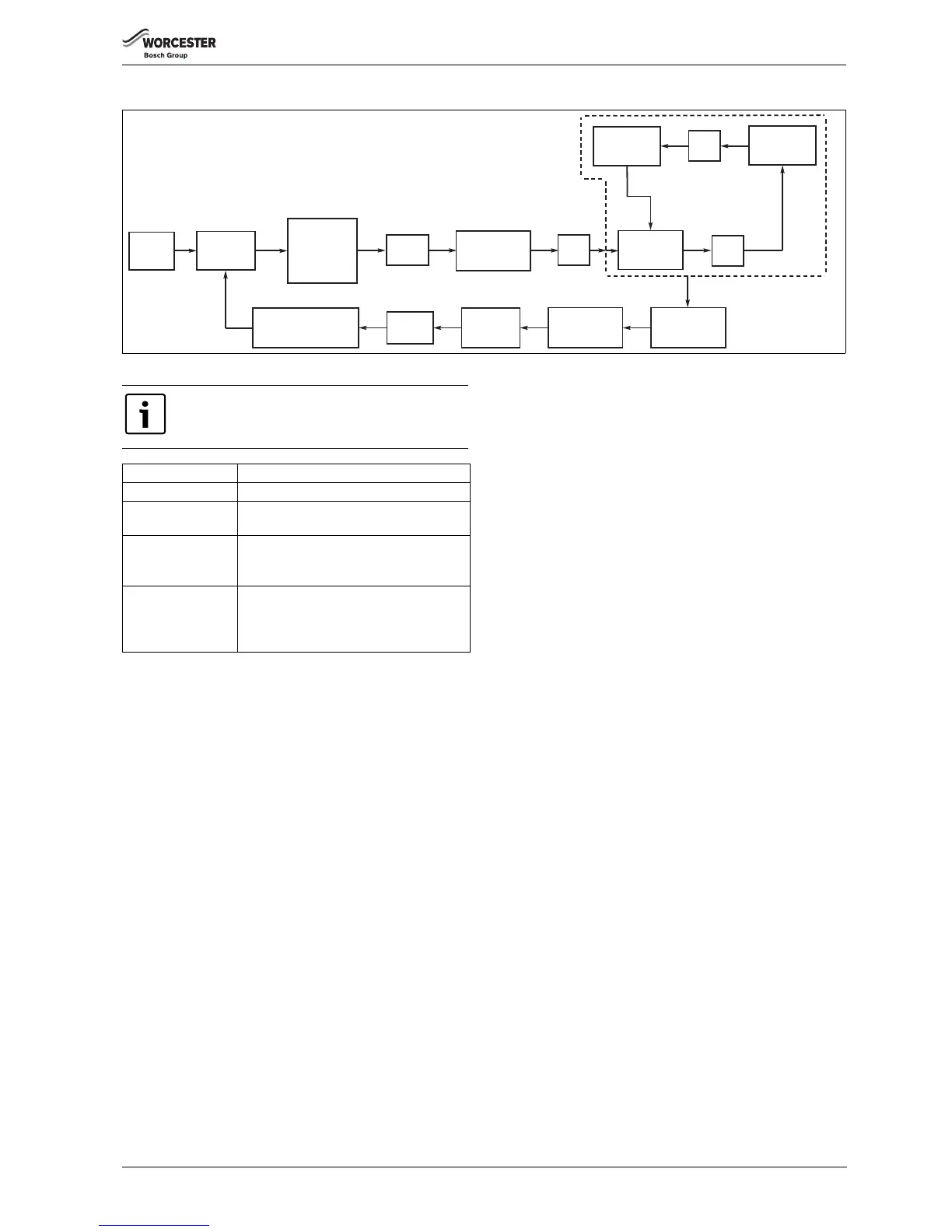

8.6 CH function chart

Fig. 91

Appliance

Mains power

supply ON

Pump OFF

3WV to DHW

[200]

230V on CH LR AND

fascia mounted

programmer CH =

ON (if fitted)

(and no current

DHW/ Heatslave tank

demand)

Anti fast cycle delay (10 minut es

from CH demand end) [202 only

displayed if a new CH demand is

started]

NO DEMAND

(system standby)

Blue light OFF

[203]

Pump overrun ON

(3 minutes from

burner OFF)

[200]

CH

DEMAND

[200]

Blue light ON

Radiator symbol on

display and 3WV to CH

[200]

Flow temp less than

CH setpoint minus

10°C

[200]

Pump

ON

[200]

Flow at more than

CH setpoint minus

CH adaptive setpoint

[200]

Burner

ON

[200]

Burner

OFF

[200]

Flow temp peaks:

CH adaptive offset

adjusted

[200]

Blue light OFF

Burner OFF Radiator

symbol off display

[200]

End of CH DEMAND

(room stat AND/ OR

programmer CH OFF)

[200]

6 720 805 209-71.1T

Numbers in square brackets are the cause code of the

current appliance operation, visible in the service menu

slot 1 (i1),

Key

3WV 3 way valve (diverter valve).

CH set point The target flow temperature set on the CH

fascia control knob.

CH adaptive offset The learnt offset temperature applied to the

CH flow so that the peak flow temperature

after burner OFF = CH set point.

Anti fast cycle delay To stop the appliance short cycling if a room

stat is intermittently calling or is poorly

positioned, there is a 10 minute delay for CH

demands timed from the last CH demand end.

Loading...

Loading...