Commissioning

Greenstar Heatslave II

ErP -

6 720 813 344 (2014/09) 33

▶ Switch off the boiler.

Clean the oil pump filter

▶ The internal filter is accessed by removing the oil pump cover

▶ Remove the oil pump filter, clean with Kerosene and refit

▶ Safely dispose of the container/discharge

Fig. 55

2. Fit a suitable pressure gauge to port [A] on the oil pump.

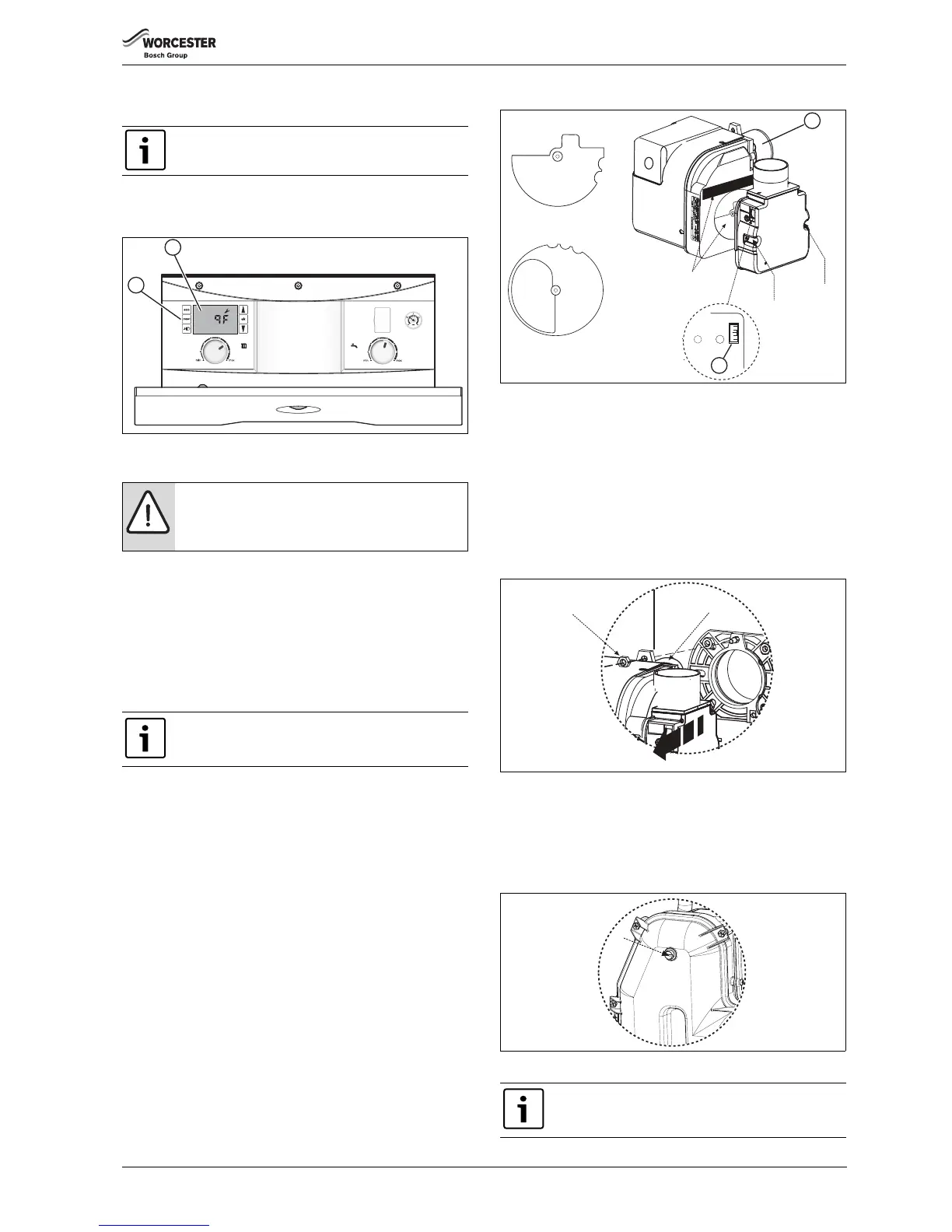

▶ 12/18 & 18/25 - RIELLO RDB 2.2

Adjust position of the air damper disc to suit the burner output

( table 8 on page 36), located as shown in figure 56. Access is by

loosening the two star screws (SC) to release the air inlet manifold.

▶ 25/32 - RIELLO RDB 2.2

No damper disk is fitted to the 25/32kW burner.

▶ Adjust the air shutter [L] (see figure 56) and pump pressure [B] as

shown in figure 54. The burner should ignite following a pre-ignition

period of approximately 15 seconds.

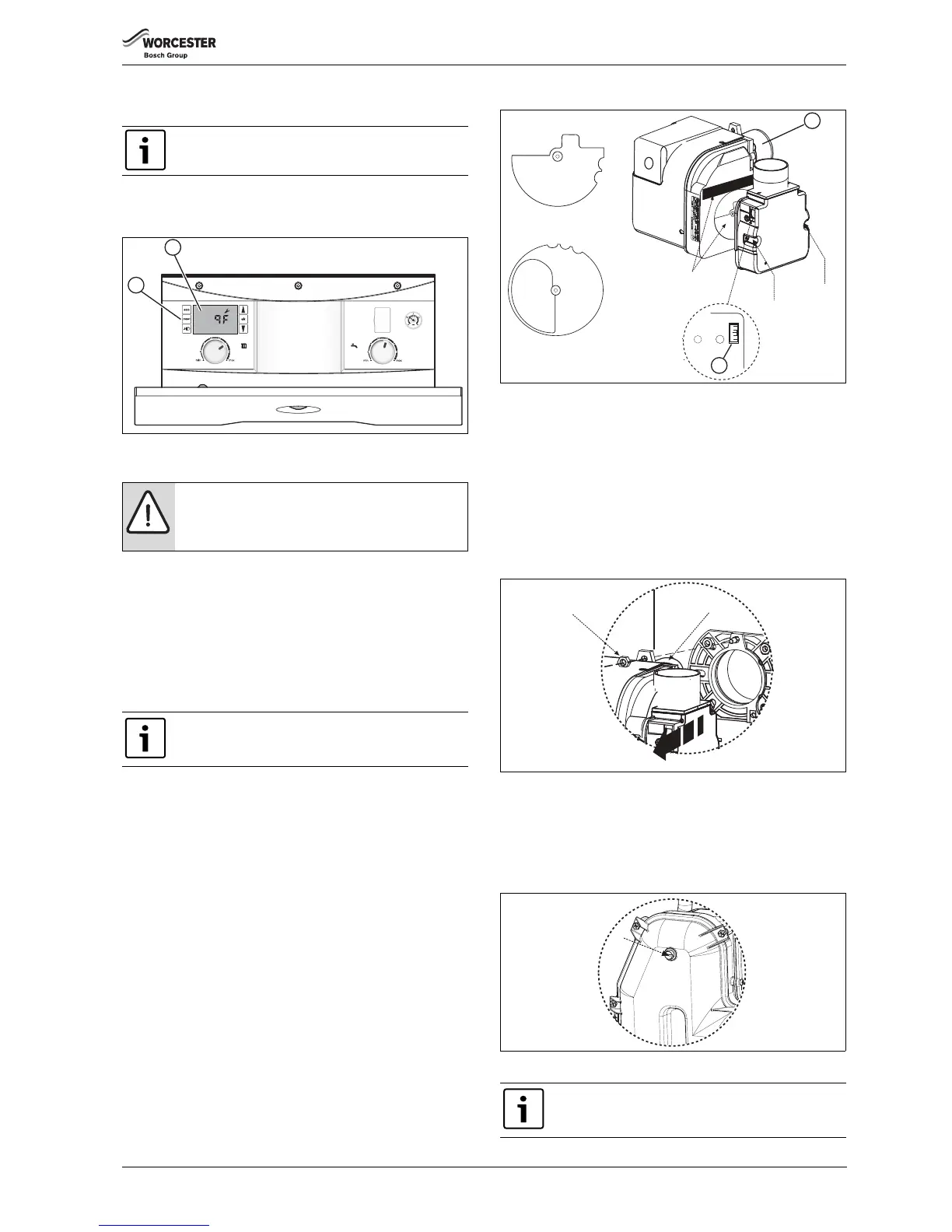

Boiler lockout

If the burner fails to establish a normal firing pattern or flame failure

occurs the flame monitoring photocell mounted in the burner body will

alert the burner control box to shut the burner down and provide a safe

lockout state indicated on the control panel LCD display [J] by code

9F 855.

▶ Wait two minutes then press the lockout reset button [K] to initiate

another start sequence.

▶ Repeat procedure until a flame is established.

Fig. 56

3. Start and run for 3 minutes then switch off.

▶ Check for after-spurting from the nozzle, indicated by oil saturation

on the combustion head [G].

If after-spurting occurs:

▶ Release the burner retainer nut [H].

▶ Remove the burner, combustion head [G]. and electrodes, hold the

burner vertical to unscrew the nozzle and fill the nozzle holder with

oil.

▶ Refit nozzle, electrodes, combustion head [G] and the burner.

▶ Restart and run for 3 minute intervals until after-spurting stops.

Fig. 57

1. Start and run for 20 minutes.

▶ Check that the oil pressure is set according to table 8 on page 36

▶ Remove sampling point plug [J] to check the smoke reading is

between 0-1. If the smoke level is above 1, check the combustion

settings are correct and the oil nozzle is in good condition.

Fig. 58

If debris is found, then the oil supply system must be

checked for the source of debris before the boiler is

commissioned.

NOTICE:

If changing the burner output, ensure the position of the

air damper disk is correct for the desired output.

Refer to table 8.

The MO535 MRF control box has an 3.5 second delay

before the start of the pre-ignition.

Loading...

Loading...