Steam Sterilizer Operation Manual

TANDA Model REV-E Page of 43

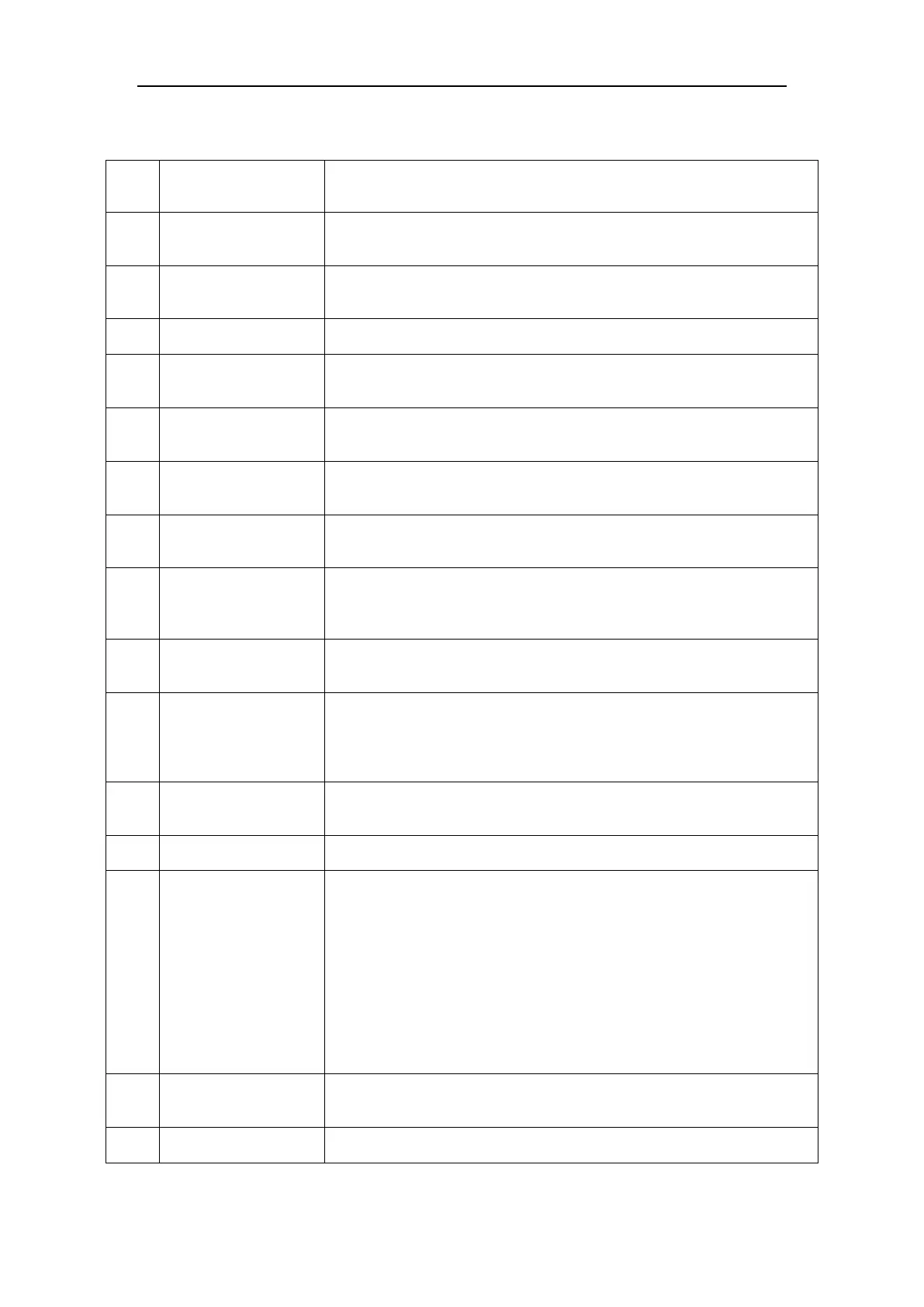

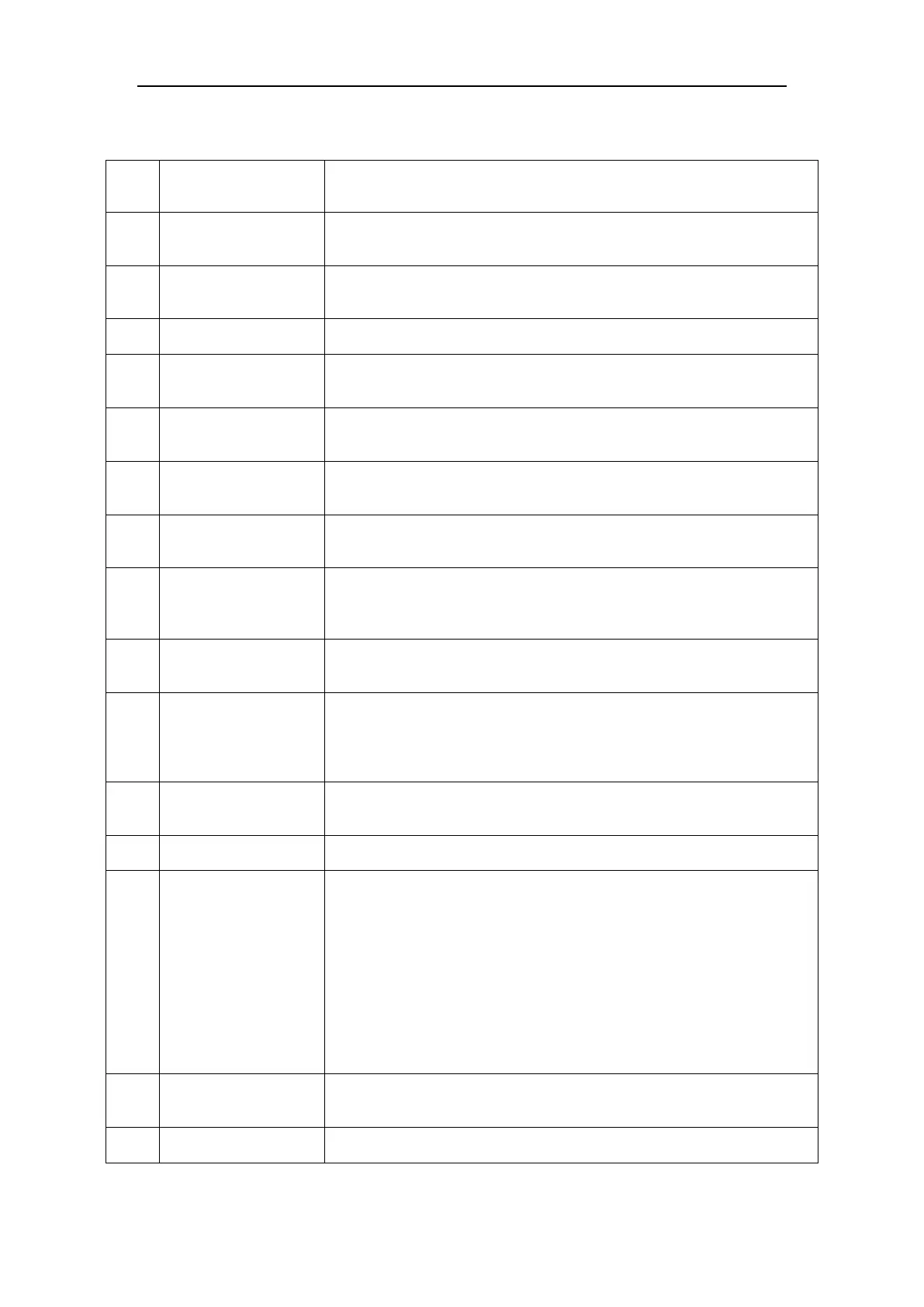

Appendix 4 The Standards of Testing

The exterior of sterilizer should be tidy and mustn’t have

disfigurements, e.g.deflection, hollowness, collision, nick, sharp edge.

The cover plate should be assured to disassemble easily in order to

repair the equipment.

The digit and letter in screen should be legible.

The electroplate should accord with YYOO76-1992 class 2, which for

the request of aspect.

The printer components should accord with YY1055-1999 the class Ⅱ

which for the request of aspect.

On the normal condition, if the sterilizer door hasn’t been locked

tightly, the program can not start.

The sterilizer should ensure that the door can’t be opened when

chamber pressure is greater than 0.27kPa.

The sterilizer must install a safety valve, safety valve opening

pressure 0.27kPa ± 0.01kPa, and automatically open when reaching

the set value.

Sterilizer should have the pre-established program about 121℃ and

134℃, dressing and instruments.

The control system in sterilizer should limit the steam which in the

chamber be controlled at the highest average temperature in ±3℃ of

pre-establish station. And ensure the temperature value accords with

the pressure controlling value.

Able to timing control of the sterilization and drying, and the error

should not be greater than 10% of the preset value.

Buttons and switches should be flexible and reliable on the sterilizer.

The indicators and displays of sterilizer should show the states of

every sterilizing procedure exactly. Under the normal situation,

sterilizer should indicate:

a) Chamber temperature

b) Chamber pressure

c) Sterilizer working state

d) Water level state

e) State of door

In the condition of the vacuum - 0.07Mpa, the sterilizer shouldn’t leak

0.13kPa/min.

The sterilizer can’t leak under the work pressure

Loading...

Loading...