ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

Before installing hoist, fill in the information below.

Refer to the Hoist and Motor data plates.

Model No. ____________________________________________

Serial No. ____________________________________________

Purchase Date ____________________________________________

Voltage ____________________________________________

Rated Load ____________________________________________

Follow all instructions and warnings for inspecting, maintaining and operating this hoist.

The use of any hoist presents some risk of personal injury or property damage. That risk is greatly increased if proper

instructions and warnings are not followed. Before using this hoist, each operator should become thoroughly familiar with all

warnings, instructions and recommendations in this manual. Retain this manual for future reference and use.

Forward this manual to operator. Failure to operate equipment as directed in manual may cause injury.

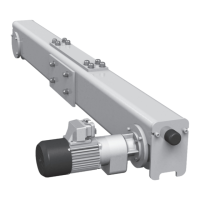

Wire Rope Hoists

Operation & Service Manual