6.9.2 Speed and Torque Measurement

SERVOPACKCONTROLOFF_ ON [

I

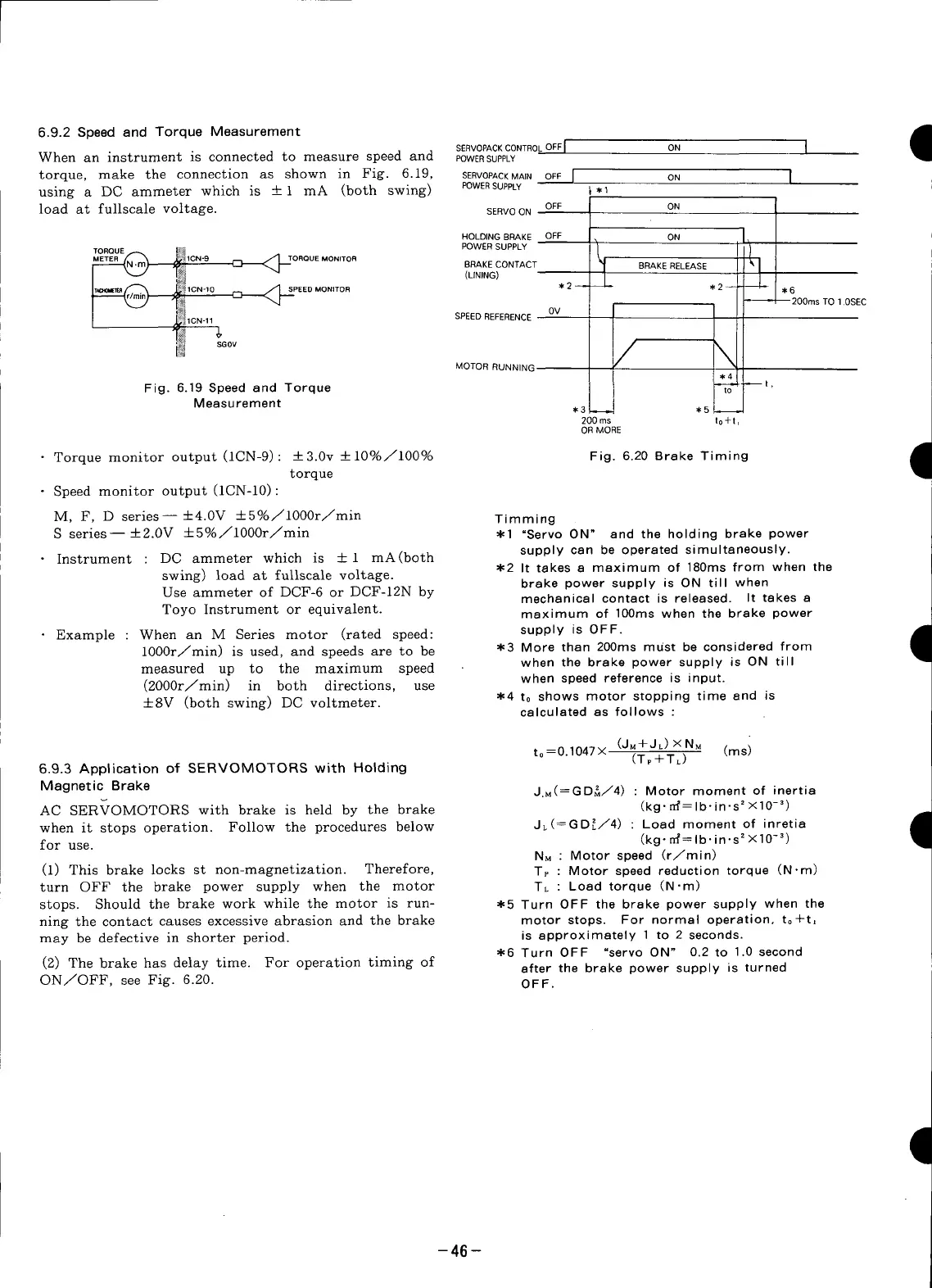

When an instrument is connected to measure speed and POWERSUPPLY

torque, make the connection as shown in Fig. 6.19, SERVOPACKMAIN OFF [ ON [

using a DC ammeter which is +_ 1 mA (both swing) POWERSUPPLy .1

load at fullscale voltage. SERVOONOFF ON

HOLDINGBRAKE OFF ON 1

_,_._ii BRAKERELEASE

_ICN-IO MONITOR (LINING) *2 -- *2 --

*6

r-n

--200ms TO 10SEC

iilCN.11 SPEED REFERENCE 0V

_!_ soov

/ I\

MOTORRUNNI

Fig. 6.19 Speed and Torque [-to_[ '

Measurement .

I /

200ms t0+t

OR MORE

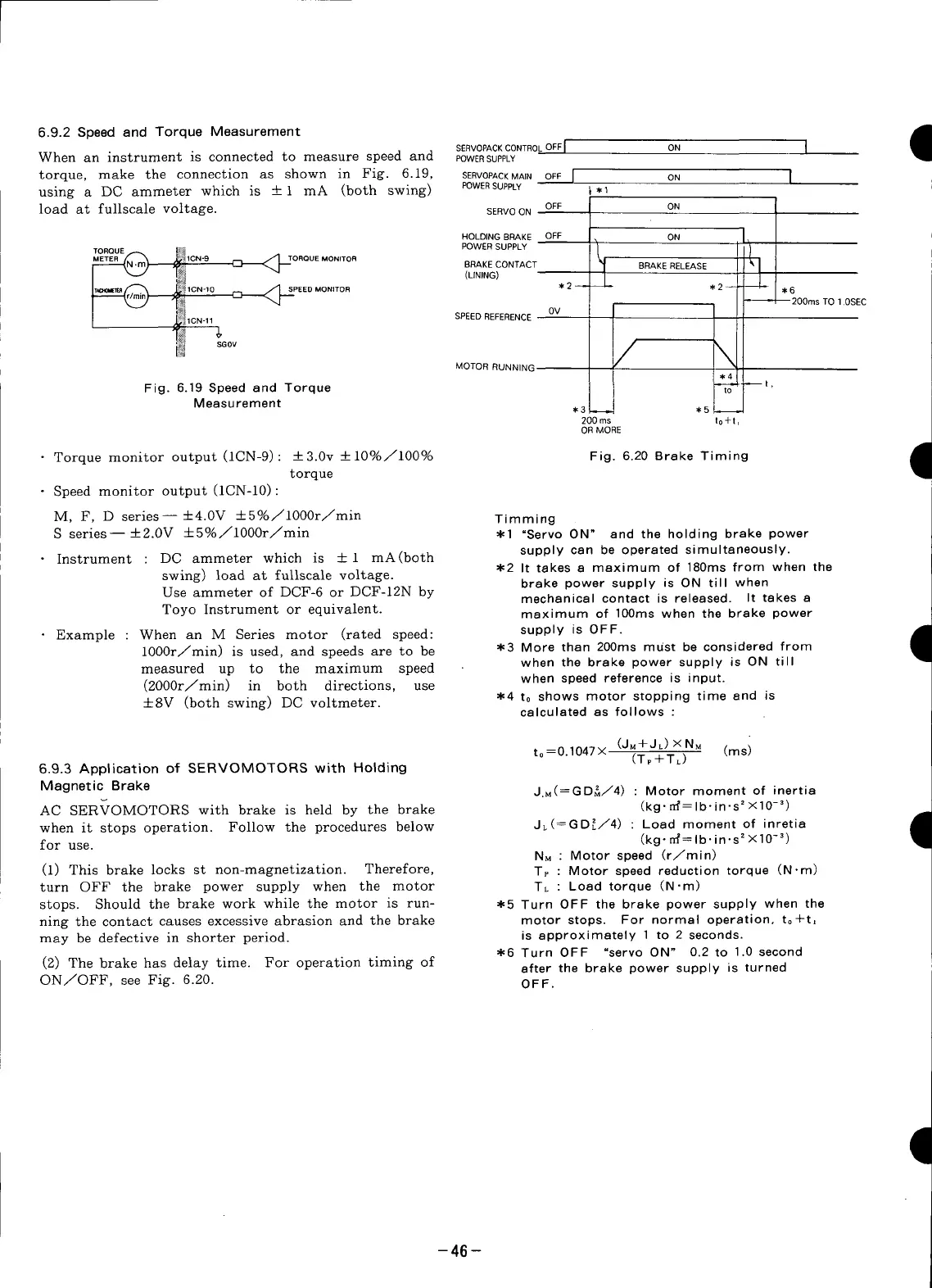

• Torque monitor output (ICN-9): +-3.0v +--10%/100% Fig. 6.20 Brake Timing i_

torque

1

Speed monitor output (1CN-10):

M, F, D series--+-4.0V __5%/1000r/min Timming

S series---I-2.0V +5%/1000r/min *1 "Servo ON" and the holding brake power

Instrument : DC ammeter which is + 1 mA(both supply can be operated simultaneously.

swing) load at fullscale voltage. *2 It takes a maximum of 180ms from when the

brake power supply is ON till when

Use ammeter of DCF-6 or DCF-12N by mechanical contact is released. It takes a

Toyo Instrument or equivalent, maximum of 100ms when the brake power

• Example : When an M Series motor (rated speed: supply is OFF.

1000r/min) is used, and speeds are to be *3 More than 200ms must be considered from

I

measured up to the maximum speed when the brake power supply is ON till

when speed reference is input.

(2000r/min) in both directions, use

+-SV (both swing) DO voltmeter. .4 to shows motor stopping time and is

calculated as follows :

(JM+JL) ×NM (mS)

t° =0"1047× (Tp+TL)

6.9.3 Application of SERVOMOTORS with Holding

Magnetic Brake J.M(=GD_/4) : Motor moment of inertia

AC SERVOMOTORS with brake is held by the brake (kg "rrf=lb'in's2×10-3)

when it stops operation. Follow the procedures below JL(_GD_./4) : Load moment of inretia

for use. (kg"rrf=Ib'in's2× 10-3)

1

NM : Motor speed (r/min)

(1) This brake locks st non-magnetization. Therefore, Tp : Motor speed reduction torque (N.m)

turn OFF the brake power supply when the motor TL : Load torque (N-m)

stops. Should the brake work while the motor is run- .5 Turn OFF the brake power supply when the

ning the contact causes excessive abrasion and the brake motor stops. For normal operation, t0+t,

may be defective in shorter period, is approximately 1 to 2 seconds.

*6 Turn OFF "servo ON" 0.2 to 1.0 second

(2) The brake has delay time. For operation timing of after the brake power supply is turned

ON/OFF, see Fig. 6.20. OFF.

-46 -

Loading...

Loading...