m

11. INSPECTIONANDMAINTENANCE

11.1 AC SERVOMOTOR

The AC SERVOMOTOR has no wearimg parts (e. g. Do not disassemble the motor, if disassembly is

brushes), so simple daily inspection is sufficient. Table necessary, contact your YASKAWA representative.

11.1 shows the inspection schedule for the motor.

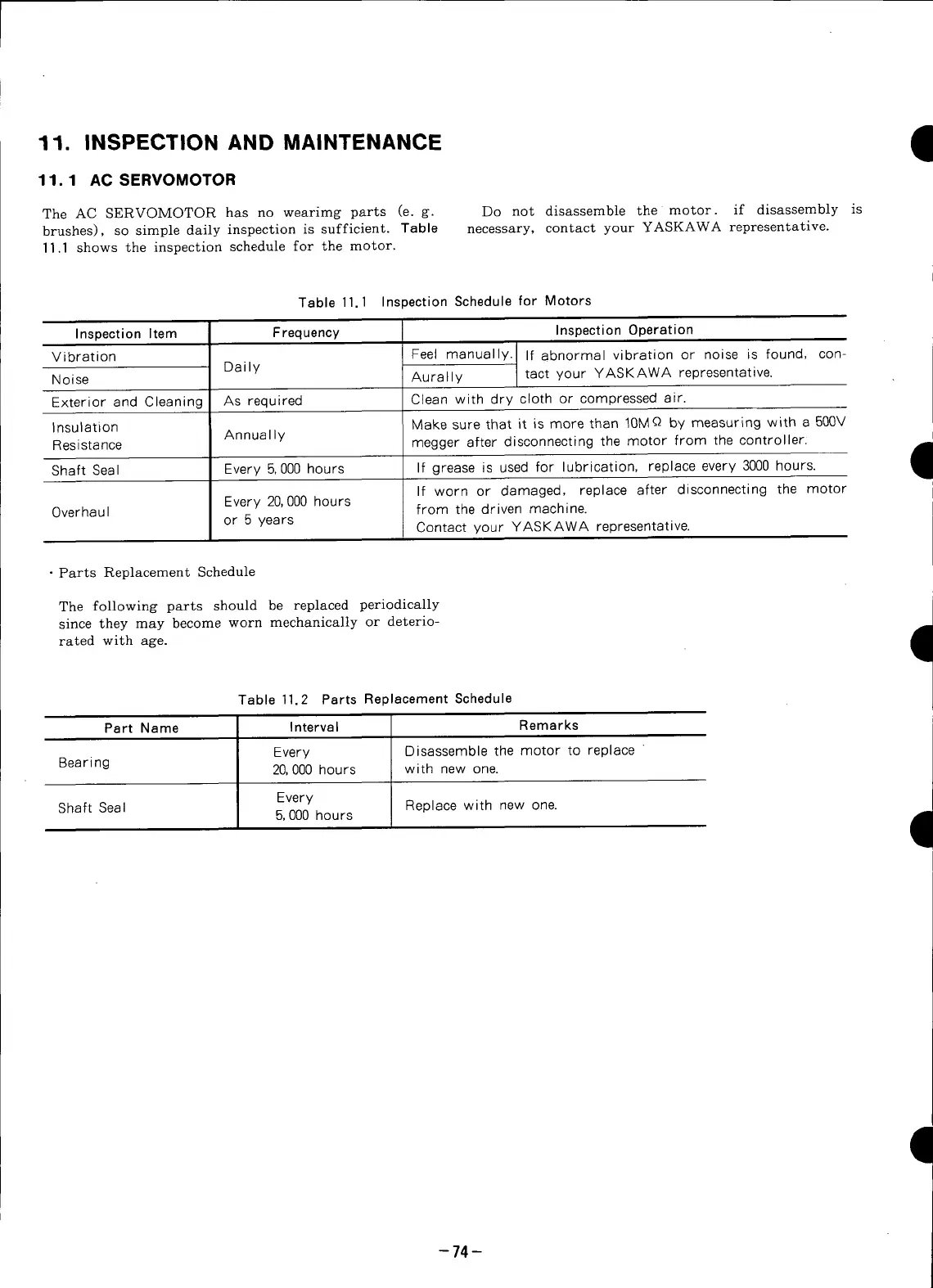

Table 11.1 Inspection Schedule for Motors

Inspection Item Frequency Inspection Operation

Vibration Feel manually. If abnormal vibration or noise is found, con-

Daily

Noise Aurally tact your YASKAWA representative.

Exterior and Cleaning As required Clean with dry cloth or compressed air.

Insulation Make sure that it is more than 10MQ by measuring with a 500V

Resistance Annually megger after disconnecting the motor from the controller:

dl

Shaft Seal Every 5,000 hours If grease is used for lubrication, replace every 3000 hours. I

If worn or damaged, replace after disconnecting the motor

Every 20, 000 hours

Overhaul from the driven machine.

or 5 years Contact your YASKAWA representative.

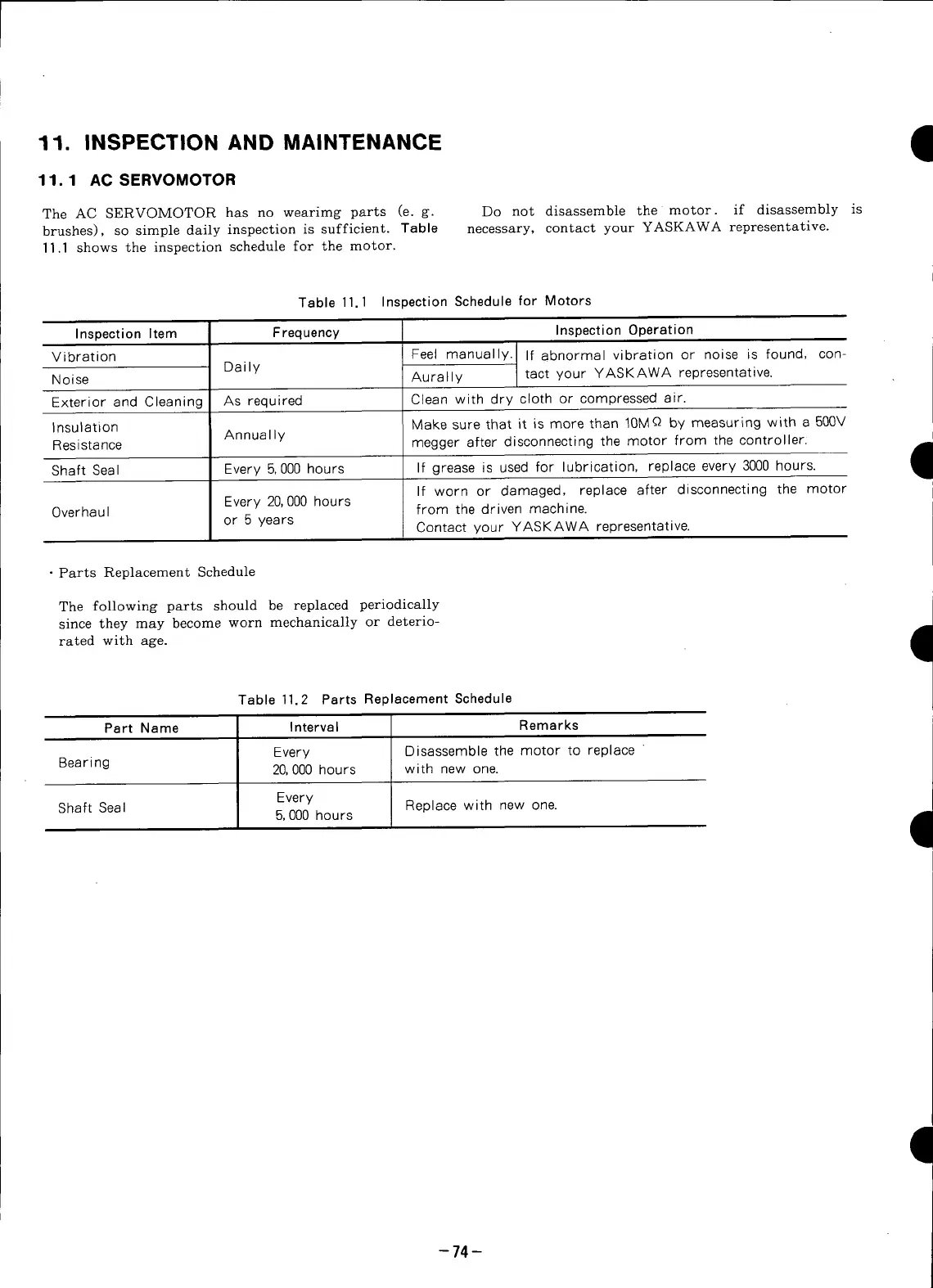

• Parts Replacement Schedule

The following parts should be replaced periodically

since they may become worn mechanically or deterio-

.din

ratedwith age.

1

Table 11.2 Parts Replacement Schedule

Part Name Interval Remarks

Every Disassemble the motor to replace "

Bearing 20,000 hours with new one.

Shaft Seal Every Replace with new one.

5,000hours _nl

I

- 74-

Loading...

Loading...