9 Maintenance and Inspection

9.3 Notes on Grease Replenishment/Exchange Procedures

9-12

159328-1CD

HW1480497

MS80W Manipulator

9.3.3 Grease Replenishment/Exchange for U-Axis Speed Reducer

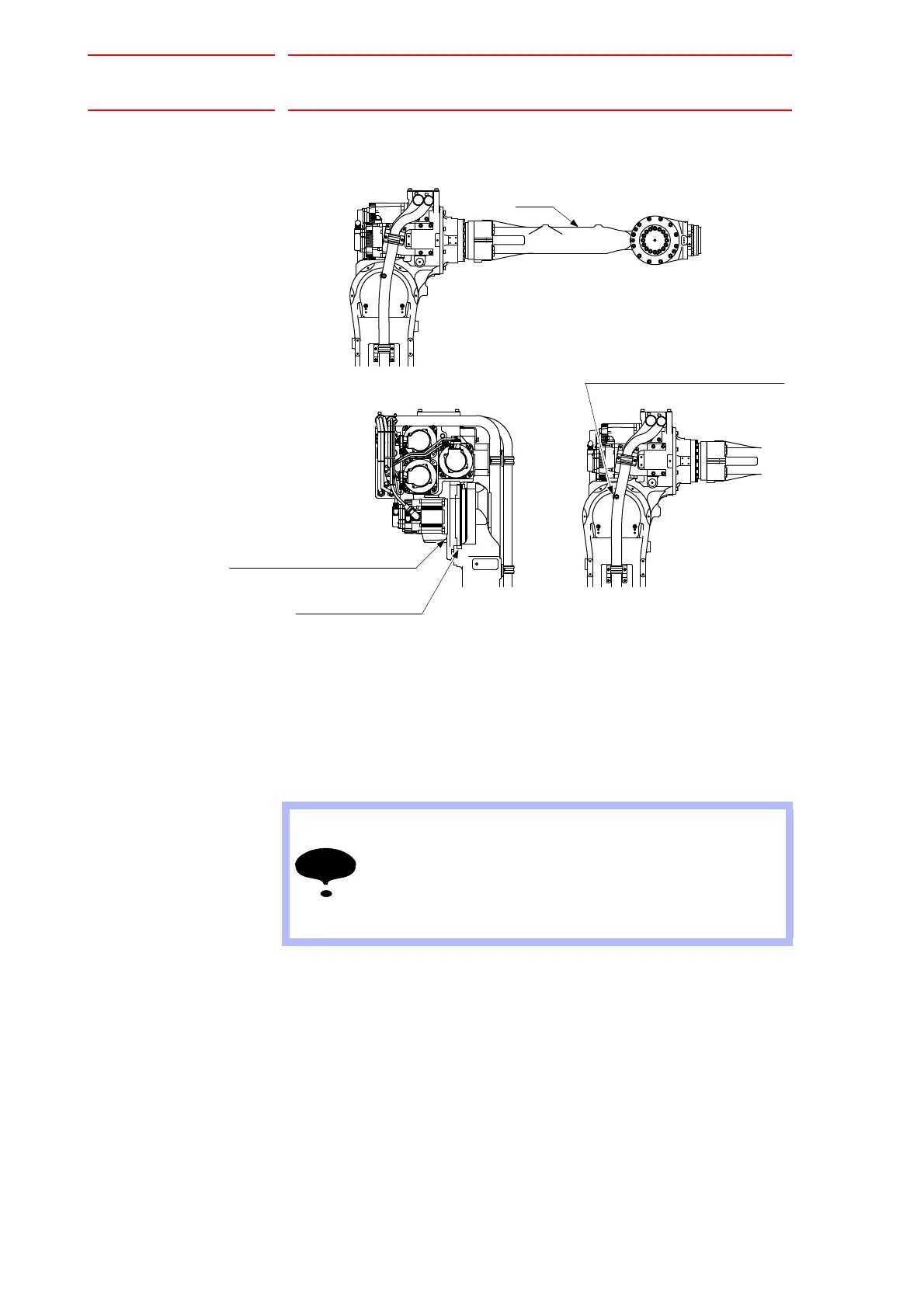

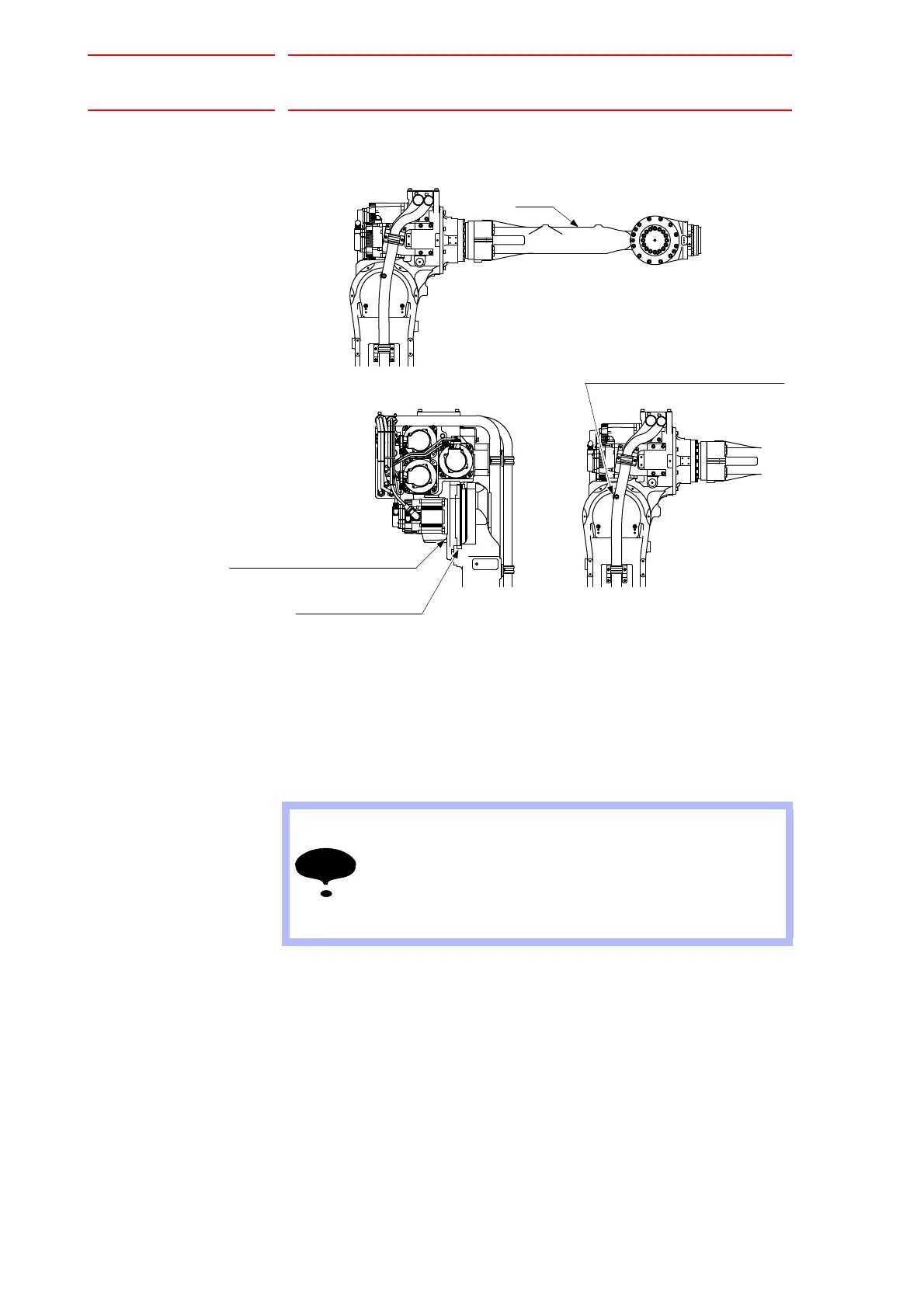

Fig. 9-6: U-Axis Speed Reducer

9.3.3.1 Grease Replenishment (Refer to Fig.9-6 U-Axis Speed

Reducer.)

1. Tilt the U-arm horizontal to the ground. (Refer to Fig 9-6.)

(The L-arm is in the vertical posture.)

2. Remove the hexagon socket head plug PT3/8 from the grease

exhaust port.

3. Remove the hexagon socket head plug PT1/8 from the grease inlet

and install the grease zerk PT1/8. (The grease zerk is delivered with

the manipulator.)

4. Inject grease through the grease inlet using a grease gun.

– Grease type: Molywhite RE.No.00

– Amount of grease: 140 cc

(280 cc for 1st supply)

– Air supply pressure of grease pump: 0.3 MPa or less

– Grease injection rate: 8 g/s or less

5. Move the U-axis for a few minutes to discharge excess grease.

U-axis speed reducer

(Hexagon socket head plug PT1/8)

Grease inlet

(Hexagon socket head plug PT3/8)

Grease exhaust port

U arm

• If grease is injected with the plug on, the grease will leak

inside the motor and may cause a damage. Make sure to

remove the plug before the grease injection.

• Do not install a joint, a hose, etc. to the grease exhaust

port. Failure to observe this instruction may result in

damage to the motor due to coming off of an oil seal.

Loading...

Loading...