9 Maintenance and Inspection

9.3 Notes on Grease Replenishment/Exchange Procedures

9-8

159328-1CD

HW1480497

MS80W Manipulator

9.3 Notes on Grease Replenishment/Exchange Procedures

Make sure to follow the instructions listed below at grease replenishment/

exchange. Failure to observe the following notes may result in damage to

motor and speed reducer.

9.3.1 Grease Replenishment/Exchange for S-Axis Speed Reducer

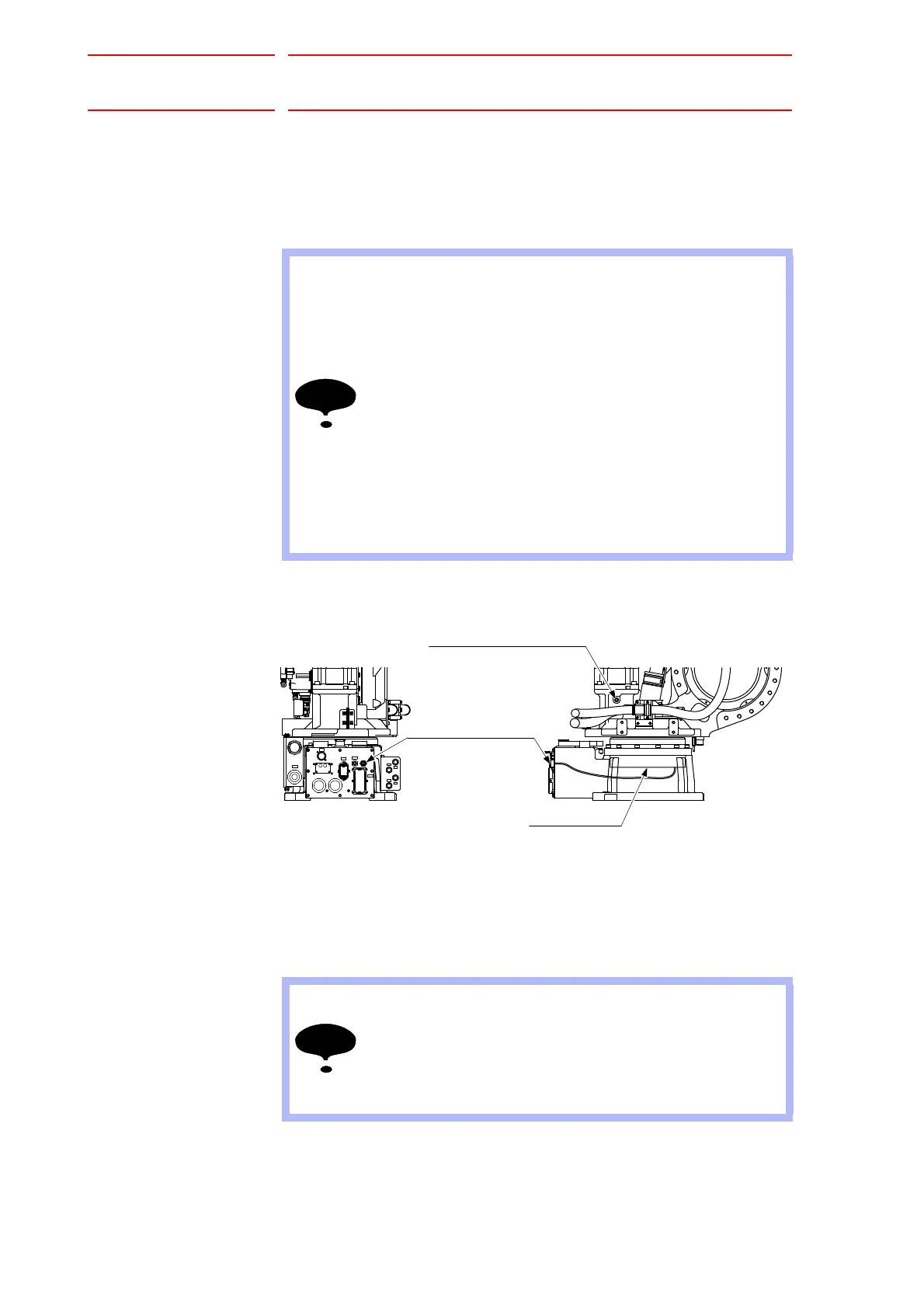

Fig. 9-4: S-Axis Speed Reducer

9.3.1.1 Grease Replenishment (Refer to Fig.9-4 S-Axis Speed

Reducer.)

1. Remove the hexagon socket head plug PT3/8 from the grease

exhaust port.

2. Remove the hexagon socket head plug PT1/4 from the grease inlet

and install the grease zerk PT1/4. (The grease zerk is delivered with

the manipulator.)

• If grease is added without removing the plug/screw from

the grease exhaust port, the grease will leak inside a

motor or an oil seal of a speed reducer will come off, which

may result in damage to the motor. Make sure to remove

the plug/screw.

• Do not install a joint, a hose, etc. to the grease exhaust

port. Failure to observe this instruction may result in

damage to the motor due to coming off of an oil seal.

• Make sure to use a grease pump to inject grease. Set air

supply pressure to the grease pump at 0.3 MPa or less,

and the grease injection rate at 8 g/s or less.

• Make sure to fill hoses, which are joined to the grease

inlet, with grease beforehand to prevent air from intruding

into the speed reducer.

• If grease is injected with the plug on, the grease will leak

inside the motor and may cause a damage. Make sure to

remove the plug before the grease injection.

• Do not install a joint, a hose, etc. to the grease exhaust

port. Failure to observe this instruction may result in

damage to the motor due to coming off of an oil seal.

(Hexagon socket head plug PT3/8)

Grease exhaust port

(Hexagon socket head

plug PT1/4)

Grease inlet

S-axis speed reducer

Loading...

Loading...