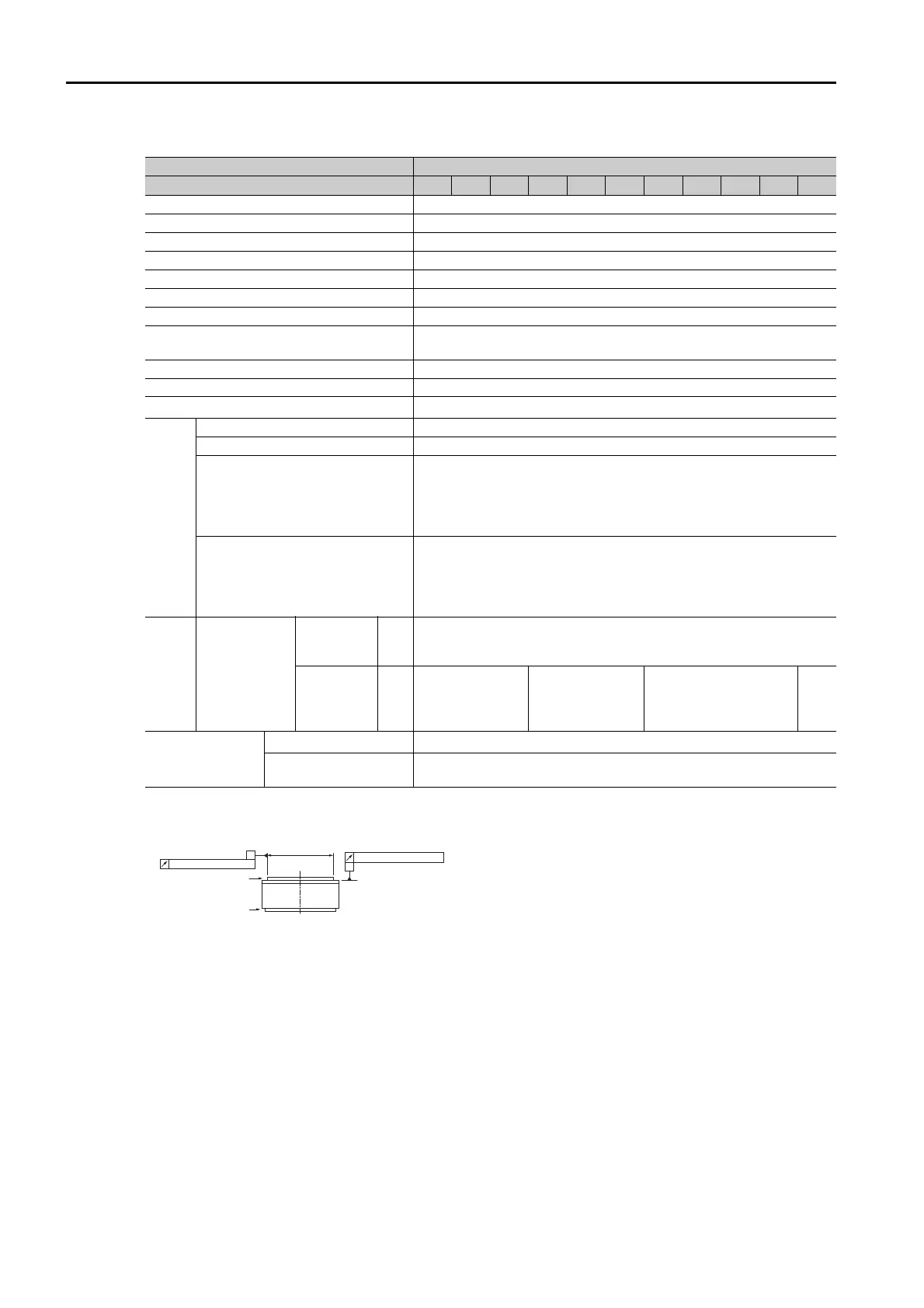

3.2 Specifications and Ratings

3.2.1 Specifications

3-4

SGM7D-

I and -

J

*1. Protective structure specifications apply only when the special cable is used.

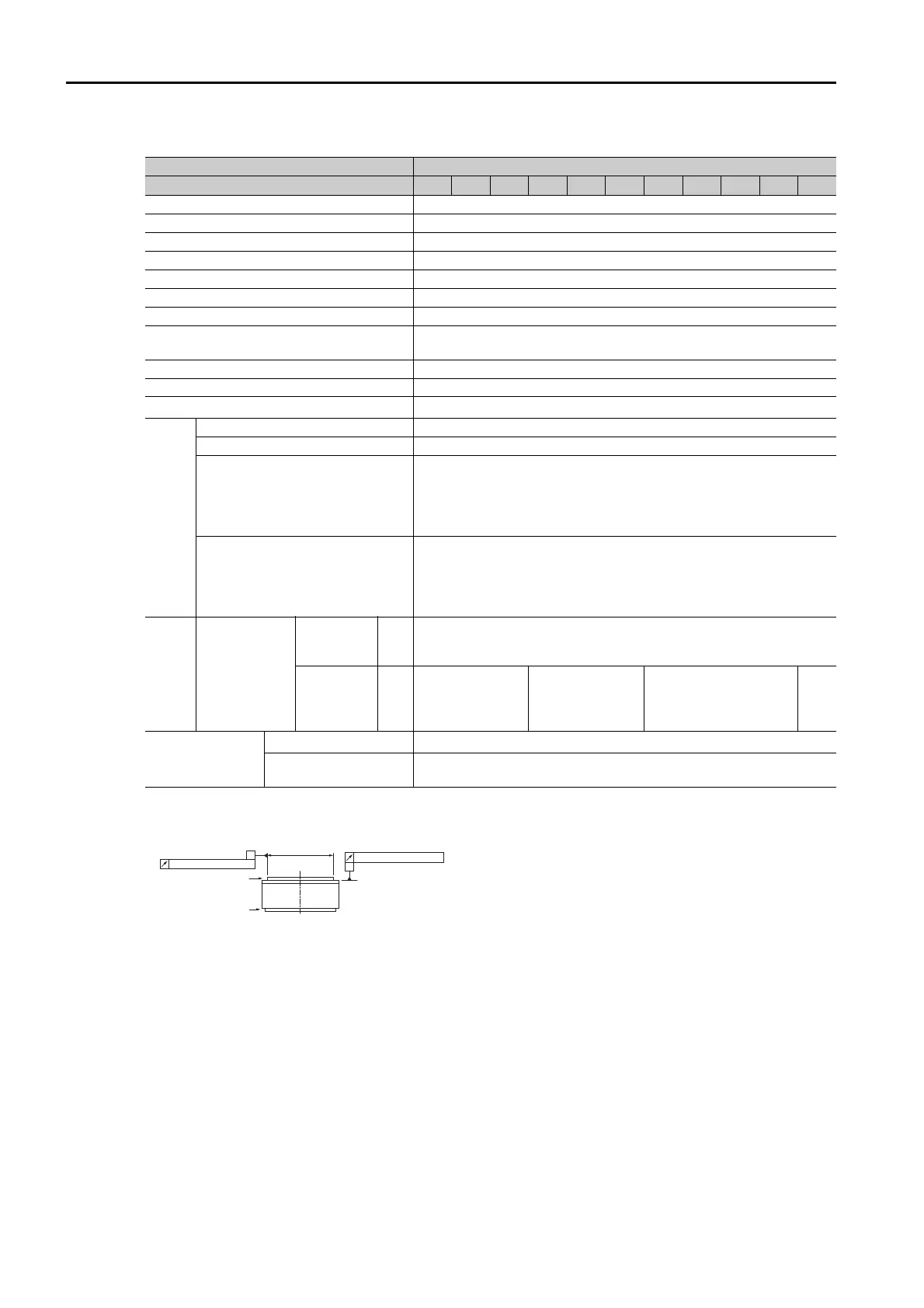

*2. Refer to the following figure for the relevant locations on the Servomotor. Refer to the dimensional drawings of

the individual Servomotors for more information on tolerances.

*3. An SGM7D Servomotor is used together with an FT-specification SERVOPACK. The following SERVOPACK

models can be used.

•

SGD7S-

A

F82

•

SGD7S-

00A

F83

Voltage 200 V

SGM7D- 28I 70I 1ZI 1CI 2BI 2DI

06J 09J 18J 20J 38J

Time Rating Continuous

Thermal Class F

Insulation Resistance 500 VDC, 10 MΩ min.

Withstand Voltage 1,500 VAC for 1 minute

Excitation Three-phase

Mounting Flange-mounted

Drive Method Direct drive

Rotation Direction

Counterclockwise (CCW) for forward reference when viewed from

the load side

Absolute Accuracy ±15 s

Repeatability ±1.3 s

Protective Structure

*1

Totally enclosed, self-cooled, IP30

Environmental Conditions

Surrounding Air Temperature 0°C to 40°C (with no freezing)

Surrounding Air Humidity 20% to 80% relative humidity (with no condensation)

Installation Site

• Must be indoors and free of corrosive and explosive gases.

• Must be well-ventilated and free of dust and moisture.

• Must facilitate inspection and cleaning.

• Must have an altitude of 1,000 m or less.

• Must be free of strong magnetic fields.

Storage Environment

Store the Servomotor in the following environment if you store it

with the power cable disconnected.

Storage Temperature: -20°C to 60°C (with no freezing)

Storage Humidity: 20% to 80% relative humidity (with no conden-

sation)

Mech-

anical

Tol e r-

ances

*2

Runout of

Output Shaft

Surface/

Runout at

End of Output

Shaft

Standard

Mechanical

Precision

mm 0.1

High

Mechani-

cal Preci-

sion

mm 0.005 0.02 0.005 0.01

Applicable

SERVOPACKs

SGD7S-

120A

*3

SGD7W-

SGD7C-

–

A

B

Load side

Non-load side

Runout of output shaft surface

Runout at end of output shaft

dia.

: Diameter determined by motor model.

Loading...

Loading...