<9. TECHNICAL DATA>

9-13

IM 01R01B02-00E-E 12th edition October 01, 2014 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

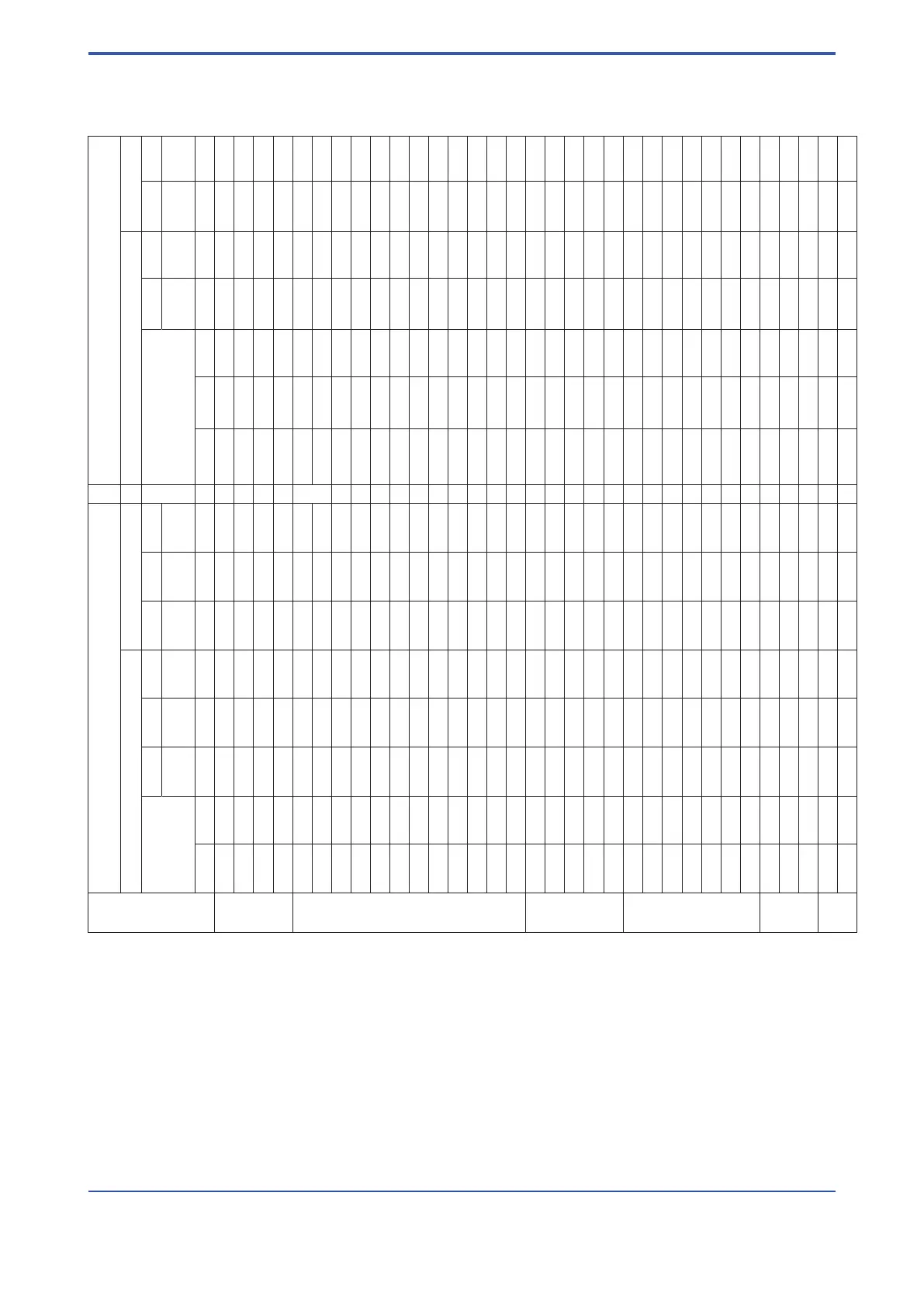

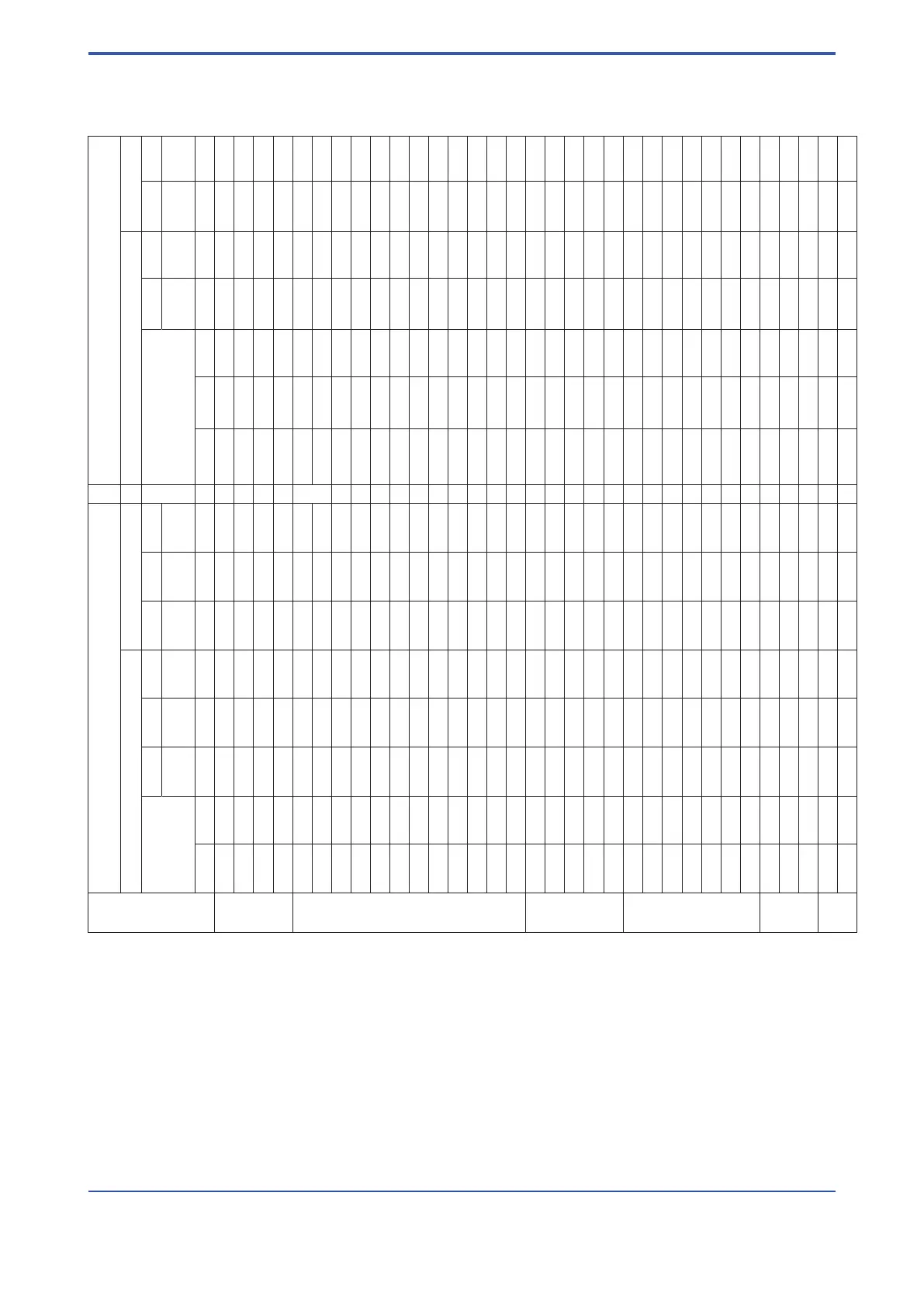

RAMC FLOW TABLES FOR METAL TUBES

Table 9-11

a)

Pressure loss at the oat with water or air.

b)

For higher viscosity the specied precision is no more guaranteed.

c)

Flow is referred to 20°C and 1 bar abs .

d)

Flow in US Gallons per minute at 70°F .

e)

Flow referred to 0°C and 1.013 bar abs at operation conditions of 20°C and 1,013 bar abs.

f)

Flow in Standard cubic feet per minute referred to 60°F and 14,7 PSI at operation conditions of 70°F und 14,7 PSI abs.

For your special application please use the Rota Yokogawa Sizing-Program.

Pos.

Measuring range for water and liquids Measuring range for air and gases

Recommended combination Alternative combination Recommended combination

Alternative

combination

Max. ow

Cone- Pressure Cone- Pressure

Max. ow

Cone- Pressure Cone- Pressure

Float-

combin.

loss

a)

Viscosity

b)

Float-

combin.

loss

a)

Viscosity

b)

Float-

combin.

loss

a)

Float-

combin.

loss

a)

m

3

/h

c)

gpm

d)

Code mbar mPa*s Code mbar mPa*s m

3

/h

c)

m

3

/h

i.N.

e)

scfm

f)

Code mbar Code mbar

1

0.025 0.11 43 S0 40 10 - - - 0.75 0 0.44 43 S0 45 - -

0.04 0.18 44 S0 40 80 - - - 1.2 1.1 0.7 44 S0 45 - -

0.063 0.28 47 S0 40 80 - - - 1.8 1.7 1.05 47 S0 45 - -

0.1 0.44 51 S0 40 80 - - - 3 2.8 1.75 51 S0 45 - -

2

0.13 0.57 53 L1 12 50 - - - 4 3.6 2.3 53 L1 13 - -

0.16 0.7 - - - 53 M1 15 10 0 5.5 5 3.2 - - 53 M1 21

0.22 1. 0 54 L1 12 50 - - - - - - - - -

0.25 1. 1 53 S1 40 100 54 M1 15 50 6.5 6 3.8 54L1 13 - -

0.32 1. 4 - - - 57 L1 12 50 9 8.5 5 - - 54 M1 21

0.4 1.8 54 S1 40 50 57 M1 15 50 10 9 5.7 57 L1 13 - v

0.5 2.2 - - - 61 L1 12 50 14 13 8 - - 57 M1 21

0.63 2.8 57 S1 40 50 61 M1 15 10 0 16 15 9 61 L1 13 - -

0.8 3.5 - - - 62 L1 12 50 22 20 12 - - 61 M1 21

1. 0 4.4 61 S1 40 100 62 M1 15 100 25 23 14 62 L1 13 - -

1. 6 7. 0 62 S1 40 100 - - - 34 32 20 - - 62 M1 21

2.2 10.1 - - - 62 V1 45 50 50 45 28 - - 62 S1 45

3

1. 3 5.7 63 L2 17 50 - - - 40 36 23 63 L2 19 - -

2.1 9.2 - - - 64 L2 17 50 50 47 29 - - 63 M2 23

2.5 11. 0 63 S2 42 30 64 M2 17 10 60 55 35 64 L2 19 - -

4 1 7. 6 64 S2 42 10 - - - 85 80 50 - - 64 M2 23

6 26.4 - - - 64 V2 43 50 120 110 70 - - 64 S2 47

4

3.2 14 67 L5 13 50 - - - 10 0 90 57 67 L5 16 - -

5.0 22 - - - 71 L5 13 50 130 120 75 - - 67 M5 25

6.3 28 67 S5 47 30 - - - 160 150 90 71 L5 16 - -

8.5 37 - - - 72 L5 13 50 200 180 115 - - 71 M5 25

10 44 71 S5 47 5 72 M5 19 5 250 230 140 72 L5 16 - -

16 70 72 S5 47 5 - - - 340 320 200 - - 72 m5 25

25 110 - - - 72 V5 63 5 500 470 290 - - 72 S5 54

5

25 110 73 V8 60 10 - - - 550 500 320 73 L8 30 - -

40 176 74 V8 60 10 - - - 850 800 500 74 L8 30 - -

63 277 77 V8 60 10 - - - 1400 1300 800 77 L8 30 - -

6

100 440 81 11 70 10 - - - - - - - - - -

130 572 82 11 70 10 - - - - - - - - - -

Loading...

Loading...