<4. Piping>

4-5

IM 11M12G01-02EN 1sh Edition : Mar. 25, 2021-00

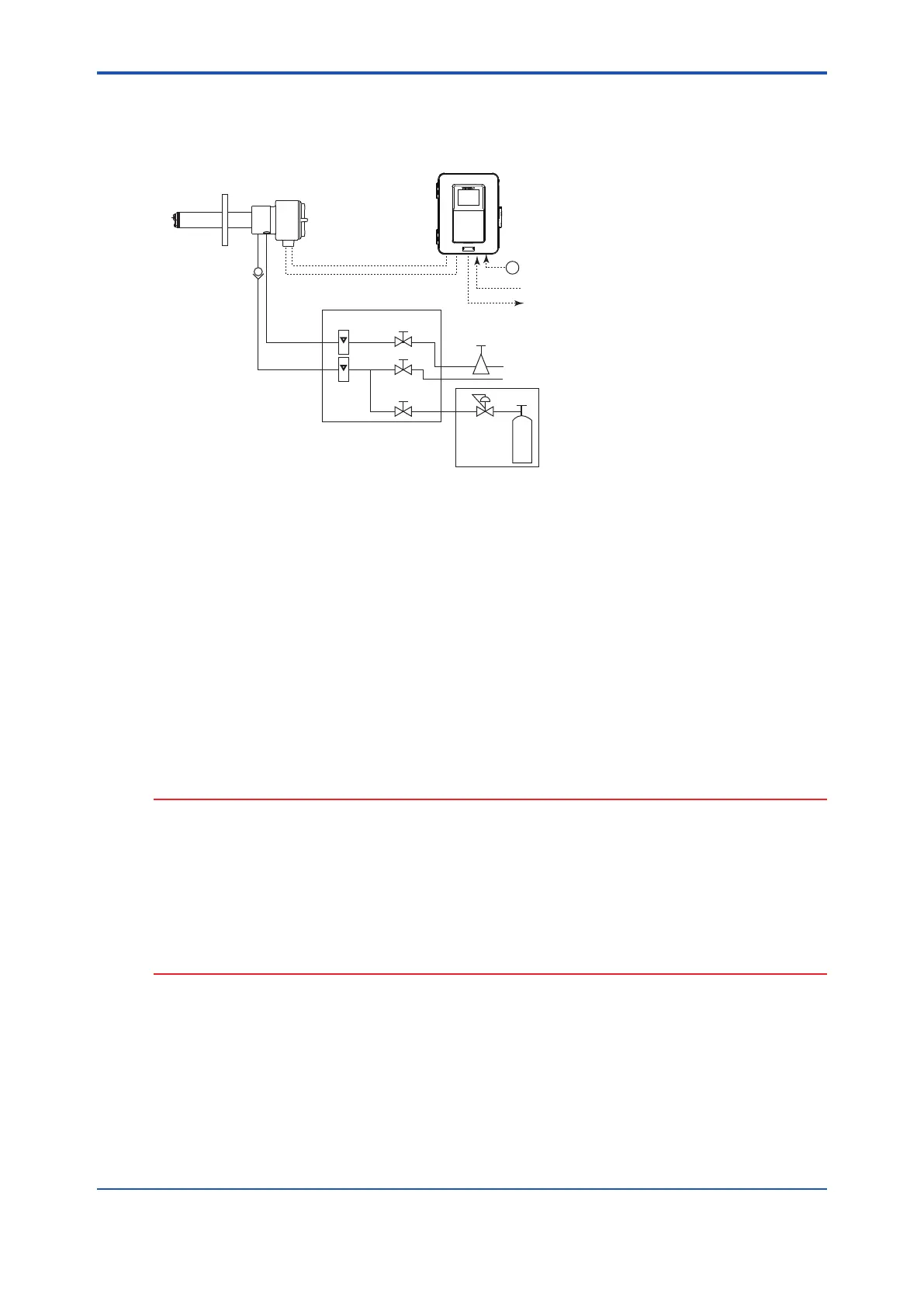

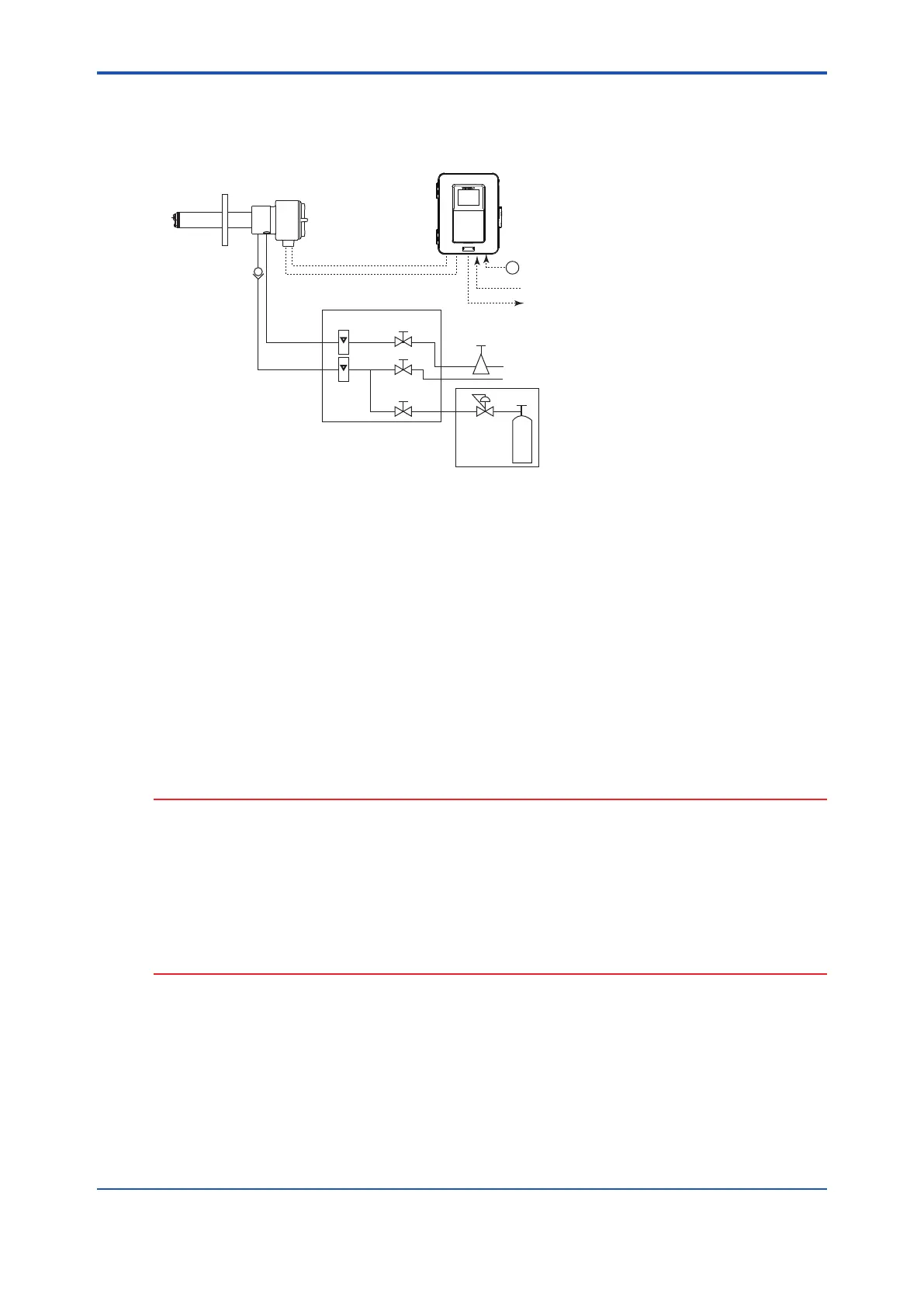

4.2 Piping for System 2

Piping in System 2 is illustrated in Figure 4.7.

~

ZA8F Flow Setting Unit

ZR22G Separate type

Zirconia Oxygen/Humidity Analyzer, Detector

ZR802G Converter

Reference

gas

Calibration

gas

Needle

valve

Flowmeter

Instrument air

Air Set

Pressure

reducing

valve

Zero gas cylinder

Calibration gas

unit case

F4-7E.ai

Stop valve

or Check valve

Span gas

(Same as Zero gas Calibration)

Signal

(6-core shield cable)

Contact input

Analog output, Contact input

Digital output (HART)

Heater (2-core)

100 to

240 V AC

Figure 4.7 Piping for System 2

• Connect a stop valve or check valve the nipple at the calibration gas inlet of the detector.

• It is recommended to use ZH21B dust protector to protect the probe output from dust

agitation (i.e., to prevent combustible materials from entering the probe cell) where humidity

measurements are made under dusty or combustible environment.

• If a high temperature detector is used and the sample gas pressure is negative, connect

an ejector assembly to the sample gas exhaust hole of the high temperature probe adapter

(see Section 4.1.4,

“Figure 4.3 Mounting the ejector assembly”).

• If a high temperature detector is used and the pressure of the sample gas is 0.49 kPa or

higher, it is recommended that a needle valve (throttle) be used in the sample gas exhaust

of the high temperature probe adapter (see Section 4.1.4,

“Figure 4.4 Mounting the

).

CAUTION

This is for lowering the sample gas temperature below 700°C. If the gas temperature is high and

700°C when reaching the detector.

On the other hand, if the sample gas temperature is lowered too much, condensation may be

produced in the high temperature probe adapter. During wintertime, it is recommended that the

high temperature probe adapter be protected with an insulating material to prevent condensation

(see Section 4.1.4,

“Figure 4.5 Preventing to condensation”).

For the usage of the high temperature probe adapter, refer to Section

“3.2.1 Usage of the

High Temperature Probe Adapter (ZO21P-H)”.

• If the dust sticking to the interior of the high temperature probe adapter is to be eliminated by

blow back while using the high temperature detector, the air feed for blow back should also

be taken into consideration.

Loading...

Loading...