<4. Piping>

4-8

IM 11M12G01-02EN 1sh Edition : Mar. 25, 2021-00

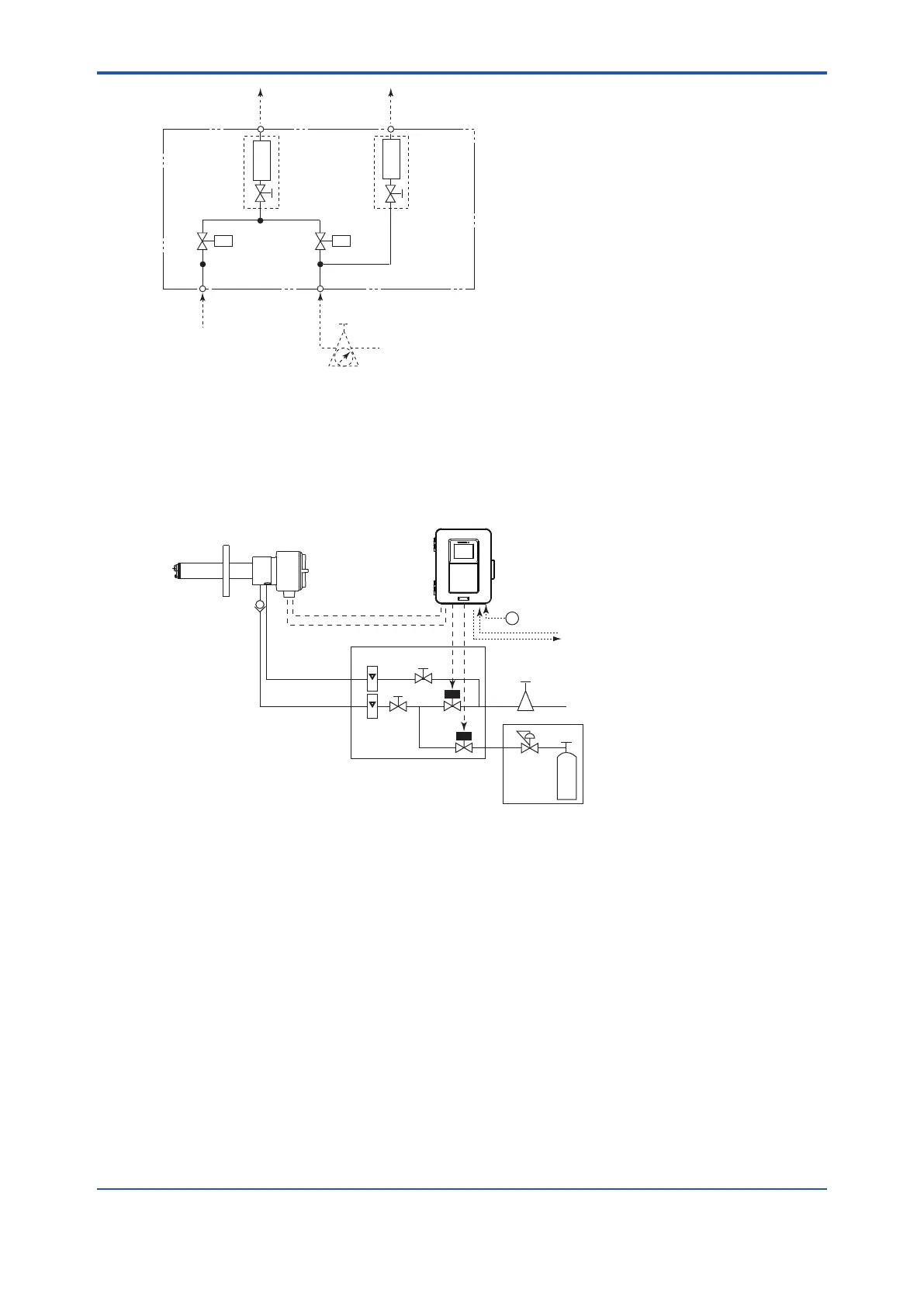

CHECK

OUT

ZERO GAS IN

AIR IN

Instrument air Approx.

1.5 l/min.

Flowmeter

Flowmeter

REF

OUT

*2 *2

EV1 EV2

Solenoid valve

EV1, EV2

F2-6-3E.ai

*2: Needle valve is supplied as accessory with flowmeter

*1 Shielded cable

Use a shielded cable for the signal cable, and connect the shield to the FG terminal of the transmitter.

*3 For zirconia type oxygen densitometers, 100 vol%N

2

gas cannot be used as zero gas. Normally, approximately 1 vol%O

2

(N

2

balanced) is used.

Figure 4.9 Piping inside in System 3

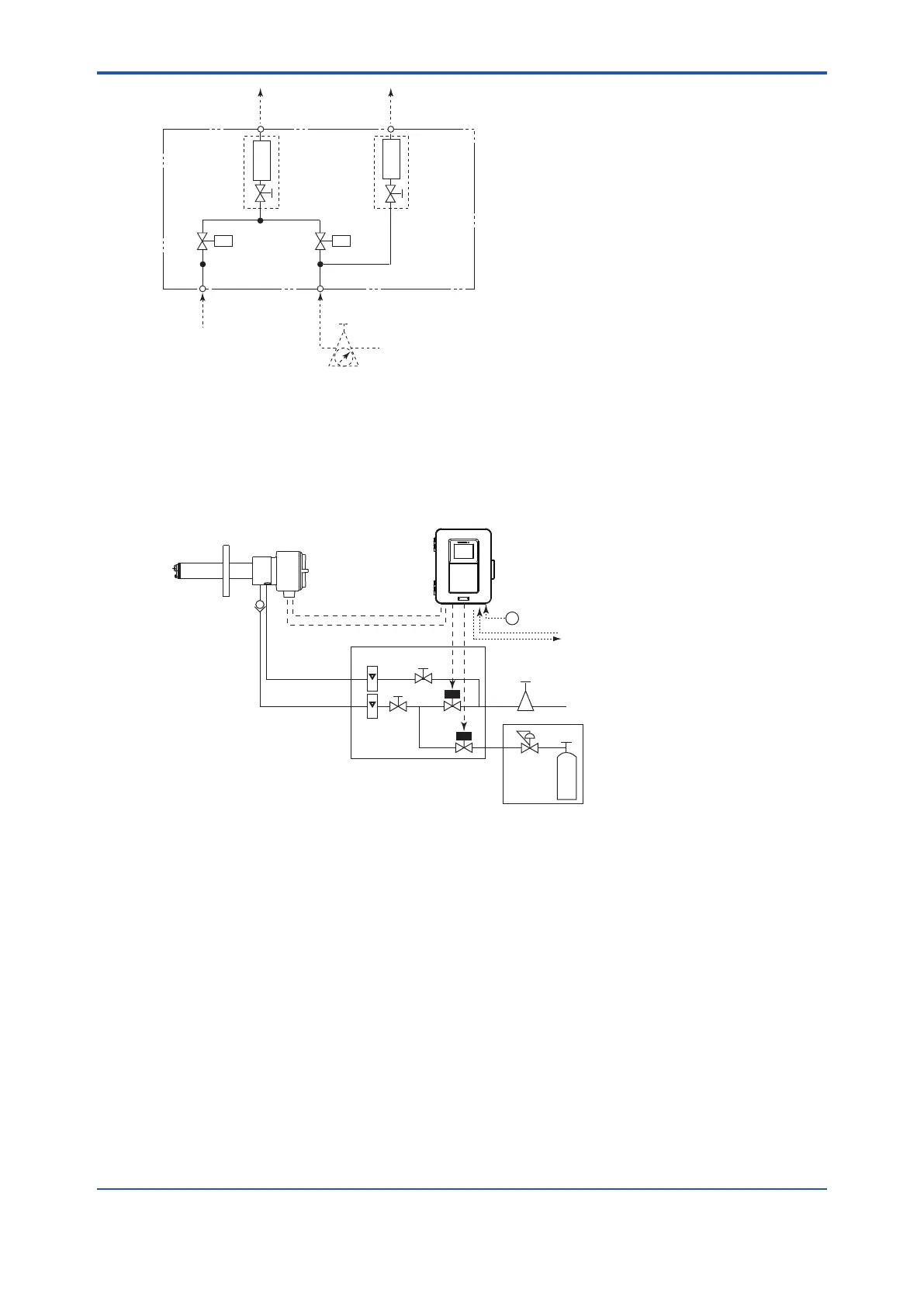

Instrument air

Pressure

reducing

valve

Air Set

Needle

valve

Flowmeter

Reference gas

Calibration gas

Check valve

~

Zero gas cylinder

ZR40H

Automatic Calibration Unit

ZR22G Separate type

Zirconia Oxygen/Humidity Analyzer, Detector

ZR802G Converter

Calibration gas

unit case

100 to 240 V AC

Contact input

Analog output, contact output

Digital output (HART)

Signal

(6-core shield cable)

Heater (2-core cable)

Figure 4.10 Piping for System 3

n Blow Back Piping

provides automatic blow back operation when the “ Blow back start “ command is entered to the

converter.

Loading...

Loading...