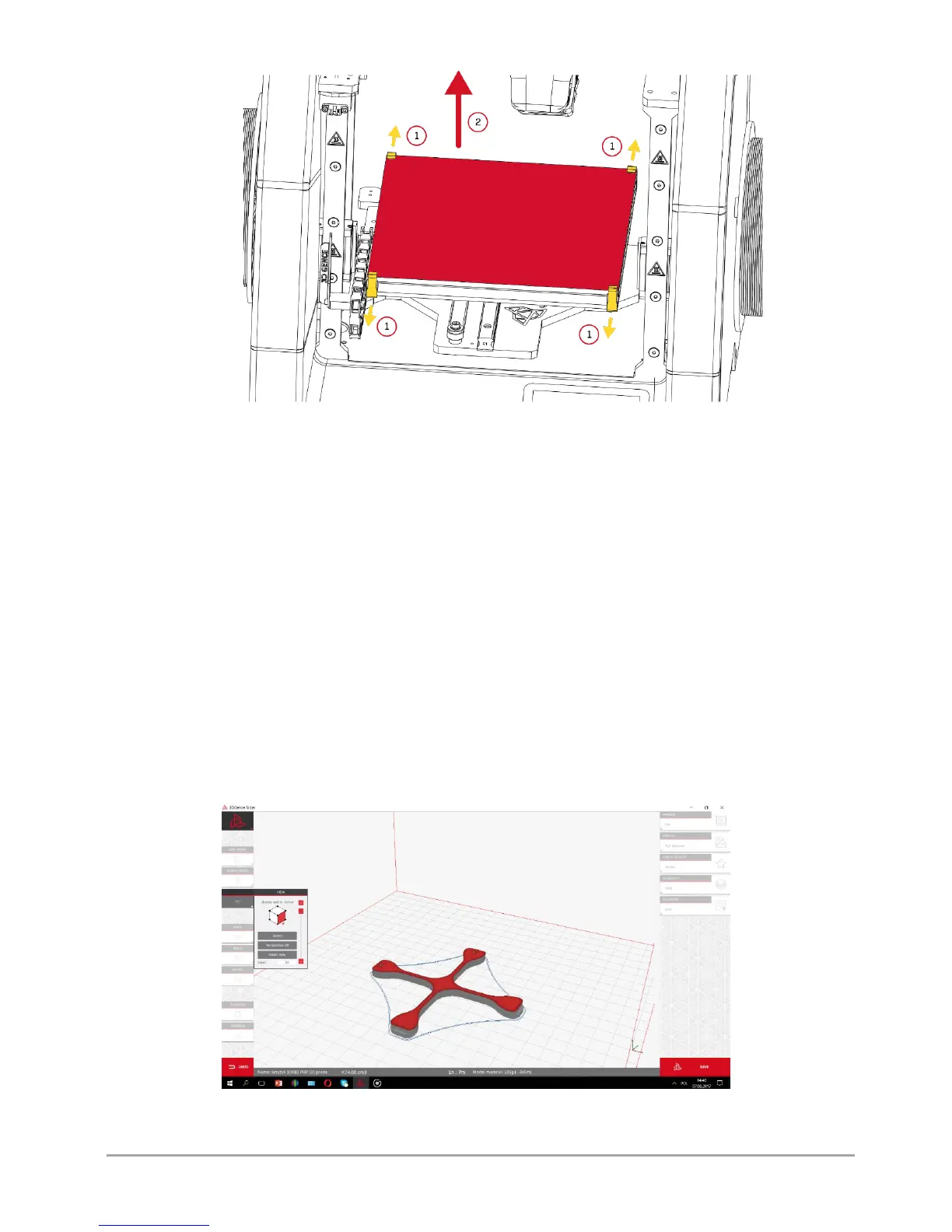

Fig. 57 Heatbed: 1. Clips | 2. Ceramic heatbed surface

2. DUAL HOTEND MODULE CALIBRATION

2.1. Precise axes calibration

3DGence DOUBLE P255 printer, like all 3DGence printers, is equipped with a unique system for precise dimensional correction

of the printed model. The printer is factory calibrated for Verbatim PLA material with the accuracy of 0.1 mm. During printing

with the use of materials having various material shrinkage levels, the dimensional correction may be necessary. In the case of

most printers, such a correction can be very troublesome or even impossible. Thanks to the innovative system, 3DGence

DOUBLE P255 printer allows you to make a precise dimensional correction in a simple and quick way. With just one calibration

printout and simple measurements, this system makes it possible to achieve the accuracy of 0.02 mm.

ATTENTION: each material from which the filament is made has its own unique thermal shrinkage. To ensure the maximum

precision of results, this calibration should be performed for the material from which the printout is to be made.

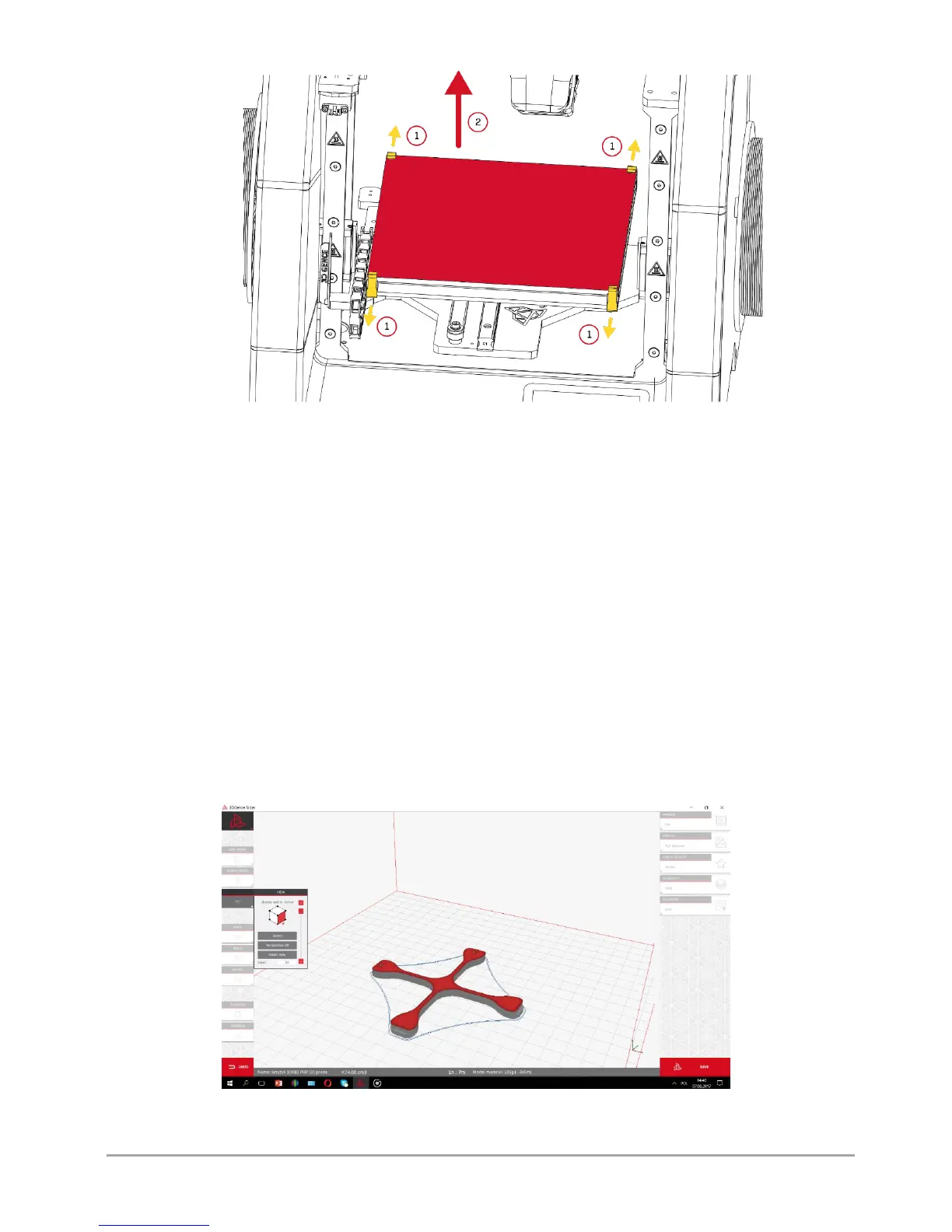

To begin the precise calibration of the XY axes, the special printout has to be made (fig. 58). Dimmension_Calibration.stl model

is available at www.3dgence/support in the Your file tab (the tab is available after creating an account and registering the

device). The model should be prepared for printing in 3DGence Slicer software for selected materials. The printout will take

about 45 minutes.

Loading...

Loading...