25

2600T SERIES | PRESSURE TRANSMITTERS | OI/266/FF-EN REV. E

Installation recommendations

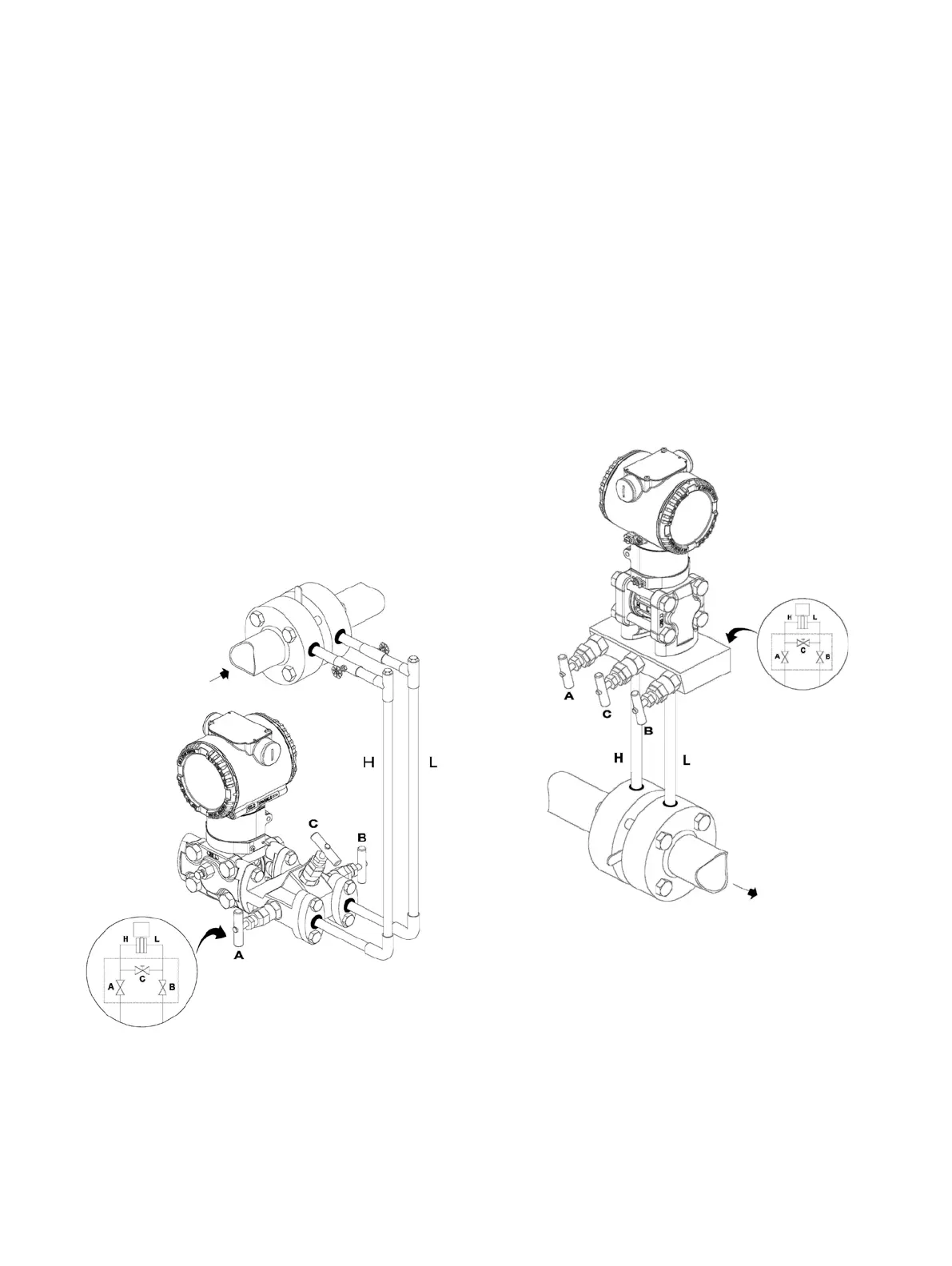

Impulse piping configuration depends on the specific

measurement application.

Steam (condensable vapor) or clean liquids flow measurement

• Place taps to the side of the line.

• Mount beside or below the taps.

• Mount the drain/vent valve upward.

• In case of steam application fill the vertical section of the

connecting lines with a compatible fluid through the filling tees.

The process fluid must enter the transmitter primary:

1 Open equalizing valve (C)

2 Close low pressure (B) and high pressure (A) valves .

3 Open gate valves

4 Slowly open high pressure (A) valve to admit process fluid to

both sides of primary.

5 Vent or drain the primary unit and then close the valves.

6 Open the (B) valve and close the equalizing valve.

Figu re 28: Steam or clean liquid flow measurement (transmitter and manifold)

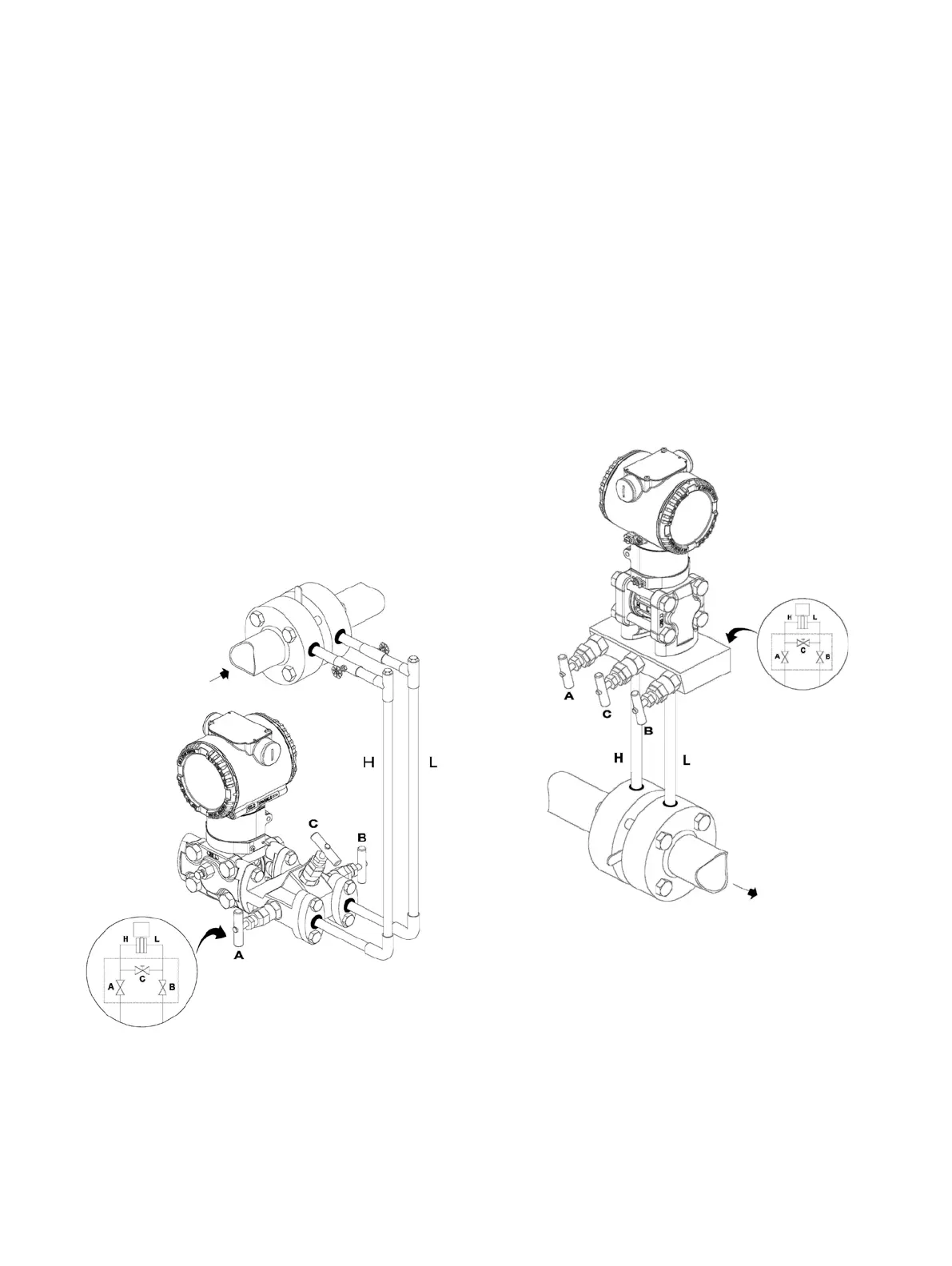

Gas or liquid (with solids in suspension) flow measurement

• Place the taps to the top or side of the line.

• Mount the transmitter above the taps.

The process fluid must enter the transmitter primary:

1 Open equalizing valve (C)

2 Close low pressure (B) and high pressure (A) valves .

3 Open gate valves

4 Slowly open high pressure (A) valve to admit process fluid to

both sides of primary.

5 Vent or drain the primary unit and then close the valves.

6 Open the (B) valve and close the equalizing valve.

Figure 29: Gas or liquid flow measurement (transmitter and manifold)

Loading...

Loading...