12

2600T SERIES | PRESSURE TRANSMITTERS | OI/266/FF-EN REV. E

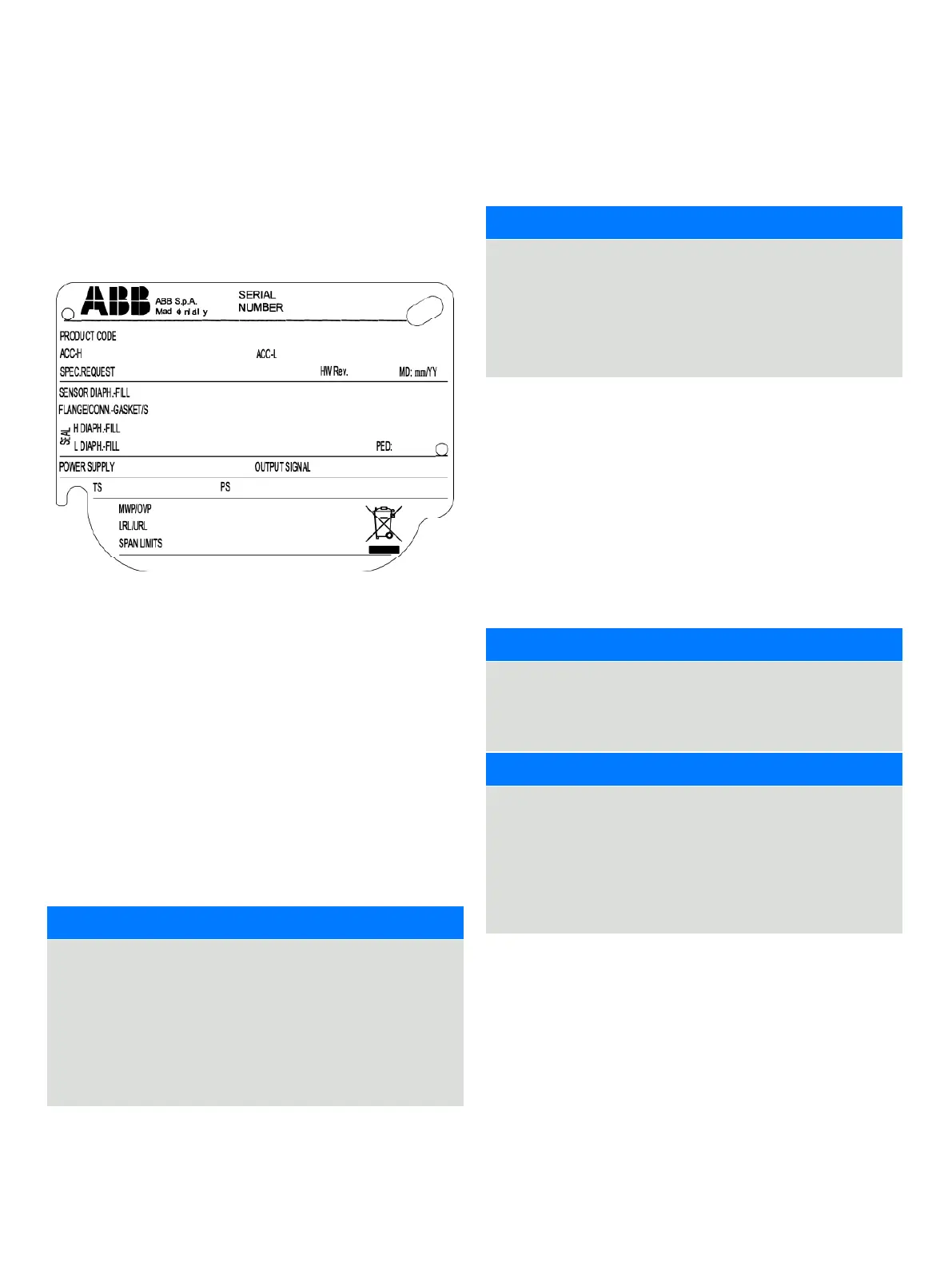

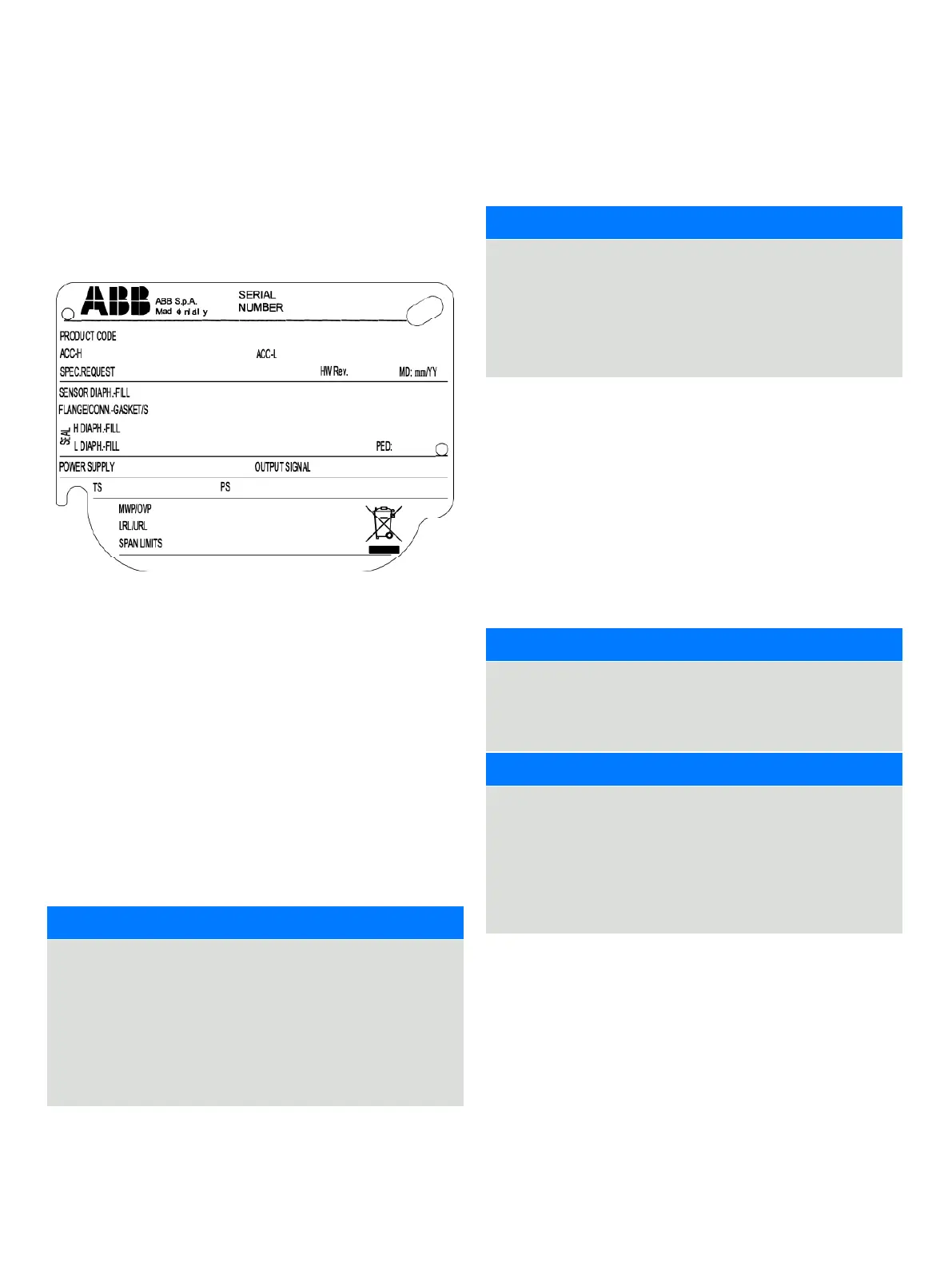

Pressure Equipment Directive (PED)

(2014/68/EU)

Devices with PS > 200 bar

Devices with a permissible pressure PS >200 bar have been

subject to a conformity validation. The data label includes the

following specifications:

Figure 5: 266 nameplate with PED data

Devices with PS ≤200 bar

Devices with a permissible pressure PS ≤200 bar correspond to

article 3 paragraph (3). They have not been subject to a

conformity validation. These instruments were designed and

manufactured acc. to SEP Sound Engineering Practices.

Mounting a DP sensor transmitter

The pressure transmitter models 266DSH, 266MST and 266RST

can be mounted directly on the manifold. A mounting bracket

for wall or pipe mounting (2” pipe) is also available as an

accessory. For models 266DRH, 266MRT and 266RRT always

mounting brackets should be used. Ideally, the pressure

transmitter should be mounted in a vertical position to prevent

subsequent zero shifts.

IMPORTANT

If the transmitter is installed inclined with respect to the

vertical, the filling liquid exerts hydrostatic pressure on the

measuring diaphragm, resulting in a zero shift. In such an

event, the zero point can be corrected via the zero push-

button or via the “set PV to zero” command. Please refer to

the following paragraph for further details. For transmitters

without diaphragm seals, please read the considerations on

the Vent/Drain.

During installation of the transmitter, zero shifts caused by

mounting (e.g., a slightly oblique mounting position due to a

remote seal, etc.) may occur; these must be corrected.

IMPORTANT

The transmitter must have reached its operating

temperature (approx. 5 min. after startup, if the transmitter

has already reached the ambient temperature).

This correction can be executed only if the Calibration

Lower Range value is 0.0 and must be made with process

(dp or p) = 0.

The correction consists in the Zero elevation/suppression

operation and can be done in two ways:

1 Locally by acting on the Z push button when the electronic

switch SW 3 is set to 0,

2 From remote station via FF communication writing 0.0 in the

PTRB_DESIRED_PRIMARY_VALUE

In case the Calibration Lower Range value is not 0.0 then the

correction cannot be made with the local Z push button, but it

can be done only from remote station via FF communication

writing the correct measure value in the PTRB_DESIRED_

PRIMARY_VALUE

IMPORTANT

After the above operations the Calibration Range Values are

not changed. The desired process output value is produced

through an internal calculation by applying an offset at the

measured value.

NOTICE

In case of a High Static differential pressure transmitter

(266DSH.x.H) please always open the equalization valve of

the manifold (if installed) before applying pressure to the

transmitter. High Static pressure can damage the sensor

causing a zero shift and a serious decrease of the total

performance in terms of accuracy. In this case, please

perform a full sensor trim.

It is important to mount the transmitter and to lay the process

piping so that gas bubbles, when measuring liquids, or

condensate when measuring gases, will flow back to the

process and not enter the transmitter measuring chamber.

Optional Vent/drain valves (code V1/V2/V3) on the transmitter

are located on the sensor flanges.

The transmitter has to be positioned so that these drain/vent

valves will be located higher than the taps on liquid service in

order to allow the venting of entrapped gas or below the taps

on gas service in order to allow the air to vent off or condensate

to drain off.

Loading...

Loading...