Planning the electrical installation

60

3. Check that the motor voltage rating meets the application requirements:

See notes 6 and 7 below the Requirements table.

4. Consult the motor manufacturer before using a motor in a drive system where the

motor nominal voltage differs from the AC power source voltage.

5. Ensure that the motor insulation system withstands the maximum peak voltage in

the motor terminals. See the Requirements table below for the required motor

insulation system and drive filtering.

Example 1: When the supply voltage is 440 V and the drive has a diode supply

and operates in motor mode only, the maximum peak voltage at the motor

terminals can be approximated as follows: 440 V × 1.35 × 2 = 1190 V. Check that

the motor insulation system withstands this voltage.

Example 2: When the supply voltage is 440 V and the drive is equipped with an

IGBT supply, the maximum peak voltage in the motor terminals can be

approximated as follows: 440 V × 1.41 × 2 = 1241 V. Check that the motor

insulation system withstands this voltage.

Protecting the motor insulation and bearings

The output of the drive comprises – regardless of output frequency – pulses of

approximately 1.35 times the equivalent mains network voltage with a very short rise

time. This is the case with all drives employing modern IGBT inverter technology.

The voltage of the pulses can be almost double at the motor terminals, depending on

the attenuation and reflection properties of the motor cable and the terminals. This in

turn can cause additional stress on the motor and motor cable insulation.

Modern variable speed drives with their fast rising voltage pulses and high switching

frequencies can cause current pulses that flow through the motor bearings, which

can gradually erode the bearing races and rolling elements.

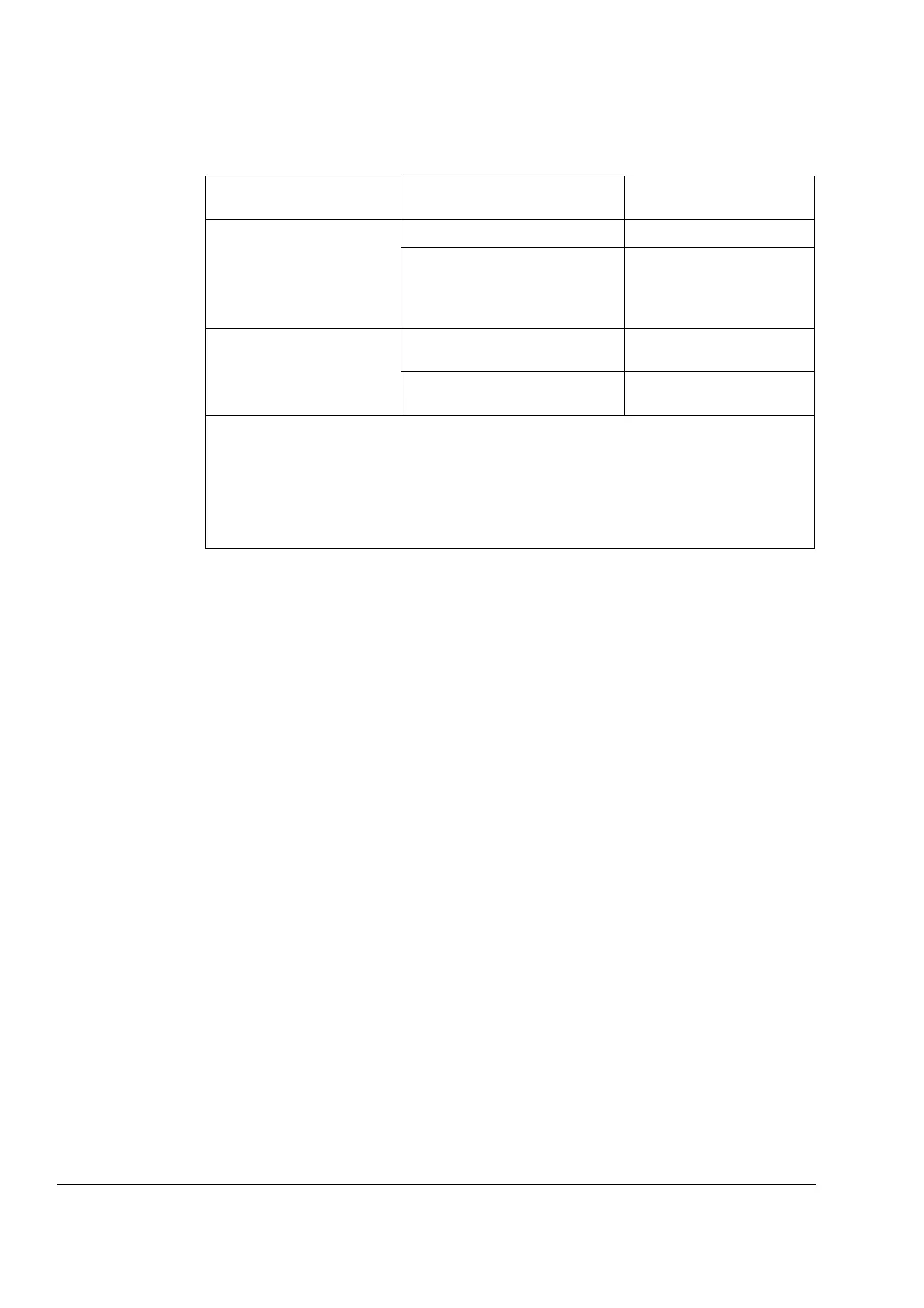

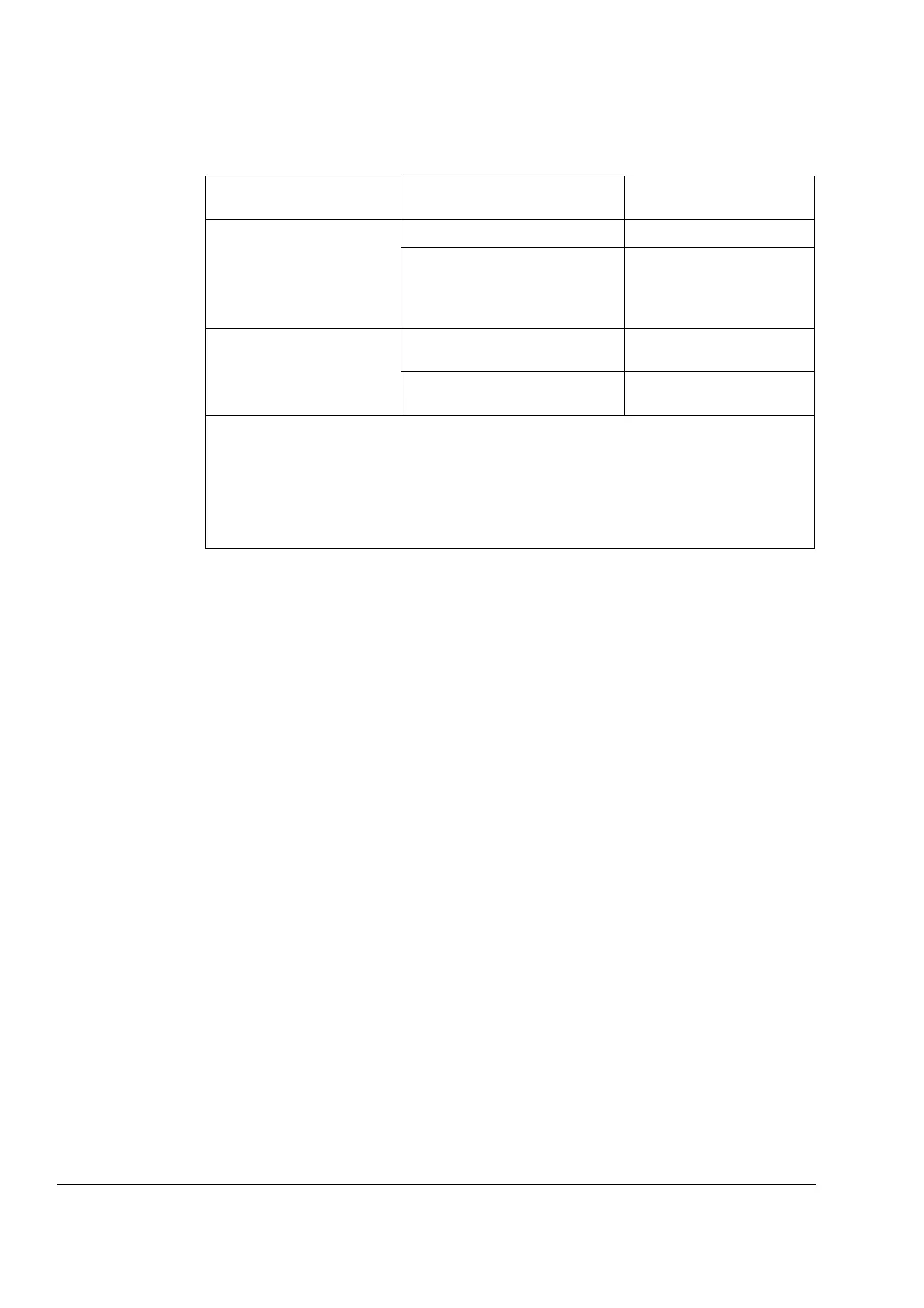

If the drive is equipped with … … and … … then the motor voltage

rating should be …

diode supply

(ACS800-01, ACS800-U1,

ACS800-02, ACS800-U2,

ACS800-04, ACS800-04M,

ACS800-U4, ACS800-07,

ACS800-U7)

no resistor braking is used U

N

frequent or long-term brake cycles

are used

U

ACeq1

IGBT supply

(ACS800-11, ACS800-U11,

ACS800-17, ACS800-37)

DC link voltage is not increased from

nominal (through parameter settings)

U

N

DC link voltage is increased from

nominal (through parameter settings)

U

ACeq2

U

N

= Rated input voltage of drive

U

ACeq1

= U

DC

/ 1.35

U

ACeq2

= U

DC

/ 1.41

U

ACeq

= Equivalent AC power source voltage of drive in V AC

U

DC

= Maximum DC link voltage of drive in V DC. For resistor braking, U

DC

= 1.21 × nominal DC link

voltage. For units with IGBT supply: see the parameter value. Note: Nominal DC link voltage is U

N

× 1.35 or

U

N

× 1.41 in V DC.

Loading...

Loading...