Planning the cabinet assembly

27

EMC requirements

Generally, the fewer and smaller the holes in the cabinet, the better the interference

attenuation. The maximum recommended diameter of a hole in galvanic metal

contact in the covering cabinet structure is 100 mm. Special attention must be paid

to the cooling air inlet and outlet gratings.

The best galvanic connection between the steel panels is achieved by welding them

together as no holes are necessary. If welding is not possible, the seams between

the panels are recommended to be left unpainted and equipped with special

conductive EMC strips to provide adequate galvanic connection. Usually, reliable

strips are made of flexible silicon mass covered with a metal mesh. The non-

tightened touch-contact of the metal surfaces is not sufficient, so a conductive

gasket between the surfaces is required. The maximum recommended distance

between assembly screws is 100 mm.

Sufficient high-frequency grounding network must be constructed in the cabinet to

avoid voltage differences and forming of high-impedance radiator structures. A good

high-frequency grounding is made with short flat copper braids for low inductance.

One-point high-frequency grounding cannot be used due to the long distances inside

the cabinet.

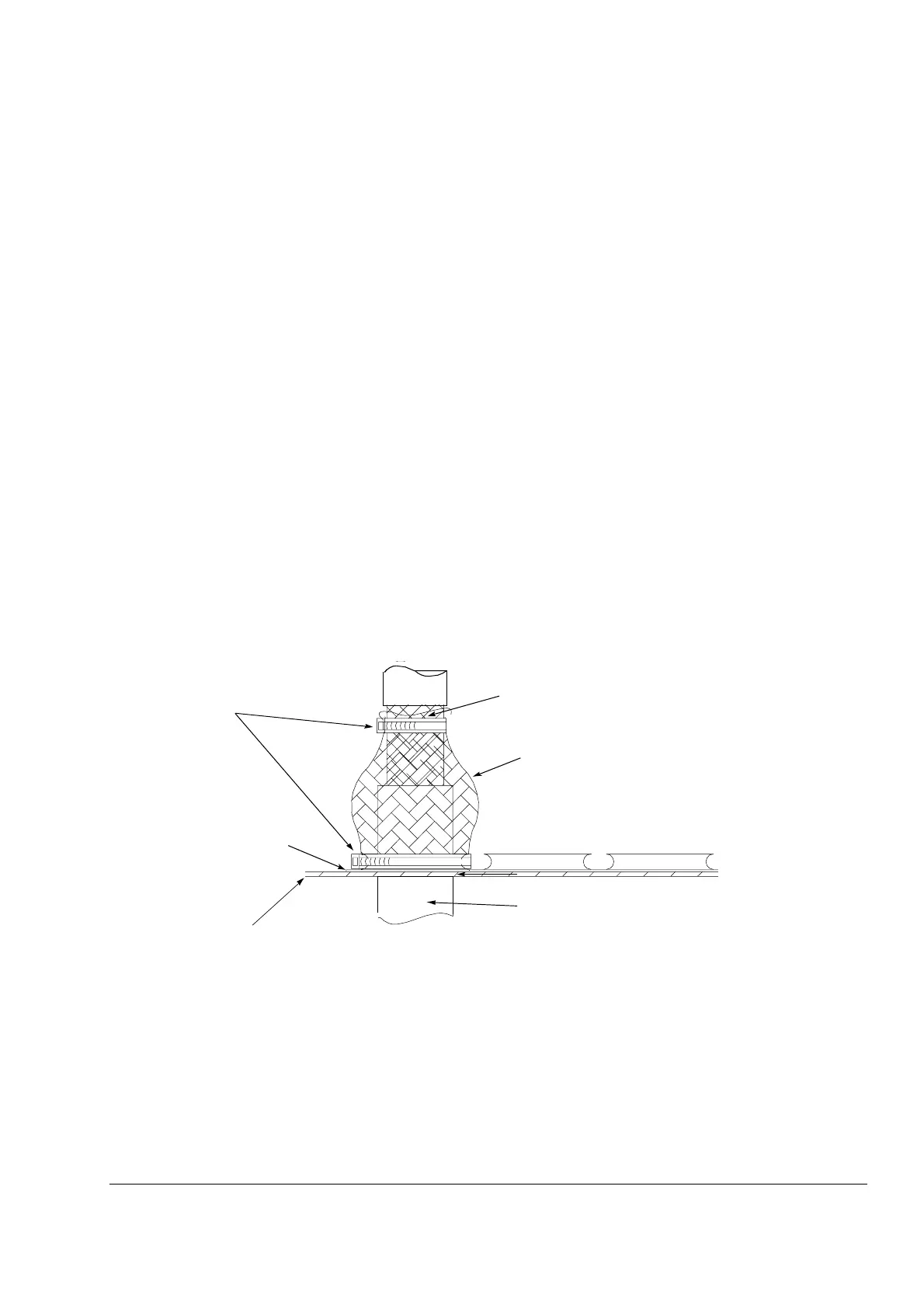

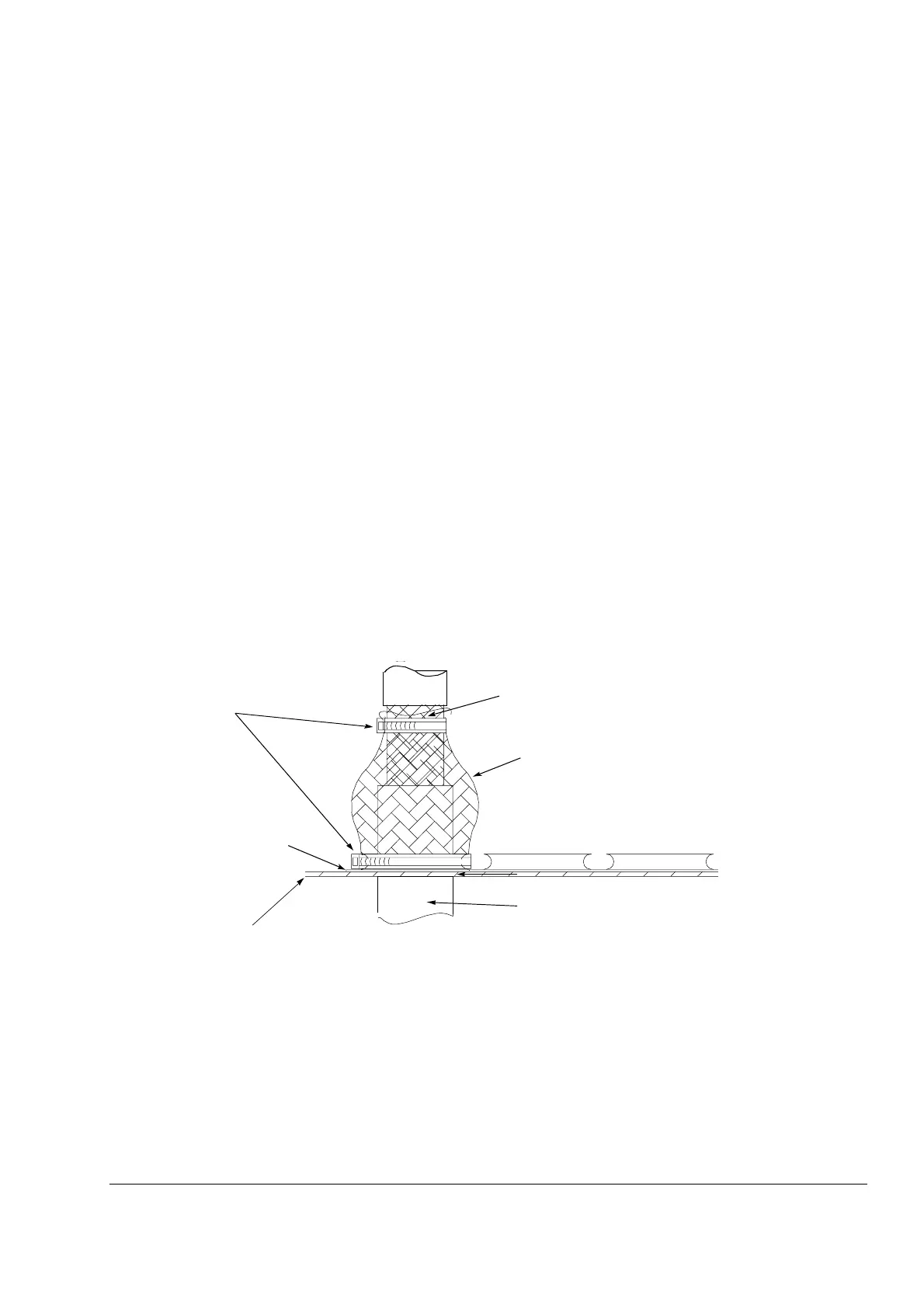

First environment EMC compliance (defined under Compliance with the European

EMC Directive in the chapter Technical data) of the drive requires 360° high

frequency grounding of the motor cable shields at their entries. The grounding can

be implemented by a knitted wire mesh shielding as shown below.

Cable ties

Knitted wire mesh

Bare cable shield

Cabinet bottom plate

Lead-through plate

Cable

Loading...

Loading...