Adtech CNC Technology Co., Ltd. 9. Program saving & editing

- 38 -

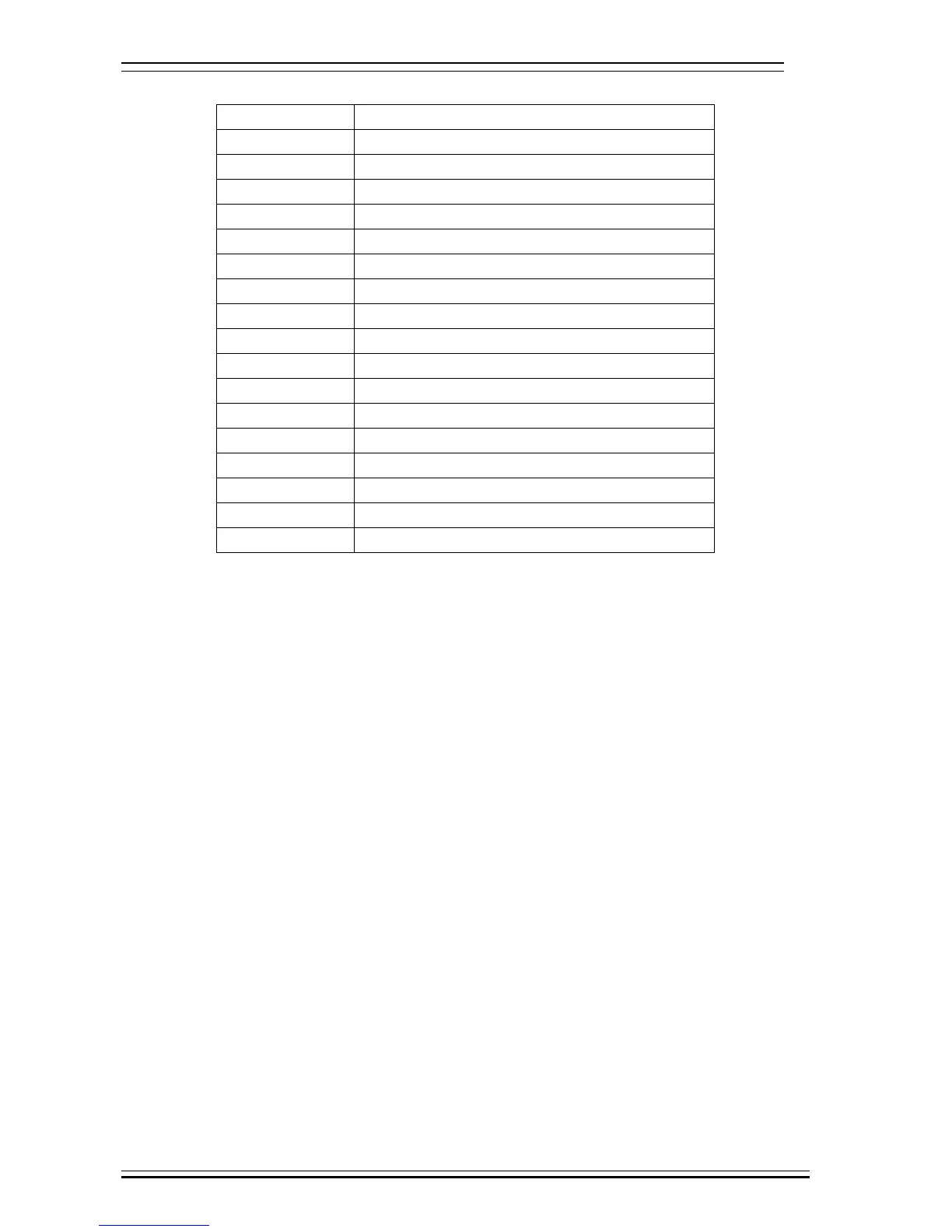

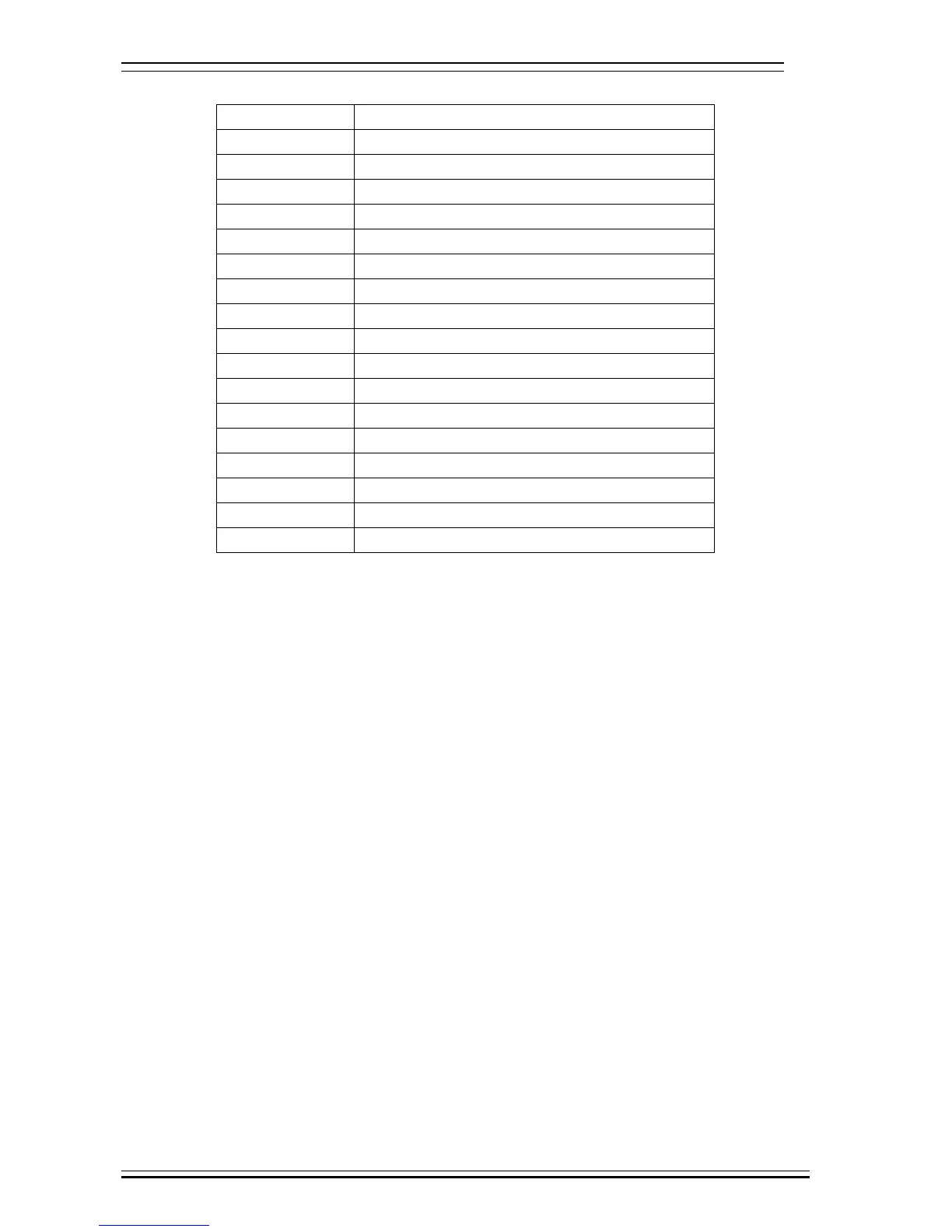

The detailed auxiliary parameters are described in the table below:

1 X coordinates offset

2 Y coordinates offset

3 Z coordinates offset

4 A coordinates offset

5 X coordinates of tool regulator

6 Y coordinates of tool regulator

7 Z coordinates of tool regulator

8 Axis selection symbol of tool regulator

9 Effective voltage level of tool regulator

10 Set tool automatically after changing

11 Tool regulator machine tool X limit

12 Tool regulator machine tool Y limit

13 Tool regulator machine tool Z limit

14 Tool regulator X search direction

15 Tool regulator Y search direction

16 Tool regulator Z search direction

17 Tool regulator limit effective signal

18 Add offset to coordinates automatically

⑴ Origin offset

¾ The origin offset is added to current machine tool coordinates when setting the coordinate system; this parameter

setting is available in next tool setting;

¾ The application of this parameter is for the processing of certain parts that require several working procedures. The first

processing procedure may damage the tool setting position of the workpiece, and the next procedure can’t locate the

proper tool setting position. Therefore, a reference tool setting point is required, and the offset from reference point to

actual tool setting position can be set to this parameter. No matter tool setting in which procedure, you only need to set

to this reference point and it is same like setting to home position of the workpiece.

⑵ Tool regulator coordinates, effective signal, automatic tool setting, machine tool Z negative limit of

tool regulator:

¾ The X, Y coordinates are the mechanical coordinates of the tool regulator on machine tool; the tool regulator can

position automatically only when the coordinate is set properly.

¾ Effective voltage level of tool regulator is to set the signal interface level of the tool regulator, which should be set

according to the actual interface of the tool regulator.

¾ Automatic tool setting after changing is that the tool regulator function executes automatically after tool changing

instruction is returned successfully to improve the processing efficiency.

¾ Z negative limit is used to prevent crash caused by not in place of Z axis error checking. Once negative limit alarm

occurs, the tool regulator stops working immediately. If the system is in processing state, the system will send abnormal

alarm; during separate setting of the tool regulator, the alarm won’t occur.

Loading...

Loading...