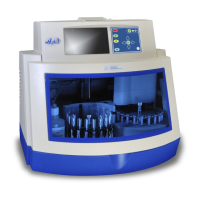

OsmoPRO MAX Automated Osmometer User Guide

68

9.1 The Diagnostics Menu

Use the Diagnostics menu to check the performance of

dierence instrument components.

1. From the Home screen, press > Diagnostics.

2. Select one of the following diagnostics functions:

Function Description/Use

A/D Analog-to-digital circuit testing

Assurance Tag Test scanning an assurance on the

assurance tag readers

Sample Probe Measure the sample probe resistance

Barcode Test the barcode scanner

LCD Inspect screen for dead pixels

Printer Test the printer

Motors/

Sensors

1

Test instrument motors and sensors

Cleaning

1

Supervisors can log fluidics cleaning and

pipettor priming.

Maintenance Supervisors can perform and log routine

cleaning, preventative maintenance, and

repairs of the instrument, and save to the

events database.

1 This function is covered in Instrument Maintenance.

9.2 Testing the Analog-to-Digital Converter

Use the A/D feature to test the analog-to-digital

converter (A/D), sample probe, block probe, cooling

assembly, and the eciency of heat transfer between the

cooling assembly components. Results are presented as

resistance (ohms), temperature (°C), and power

level(%).

1. From the Home screen, press Diagnostics > A/D.

2. Select the Probe option.

3. Select a Set Point temperature to adjust the

temperature for the cooling assembly (sample block,

freeze block, and cold block).

4. Press Start.

After five minutes, the block temperature should

roughly equal the set point temperature.

NOTE: Power level is expressed as a percentage,

indicating how much power the thermoelectric

cooler uses to reach a temperature set point

sensed by the block probe. An increasing

power-level requirement indicates deteriorating

performance of the cooling assembly.

Chapter 9: Diagnostics

Loading...

Loading...