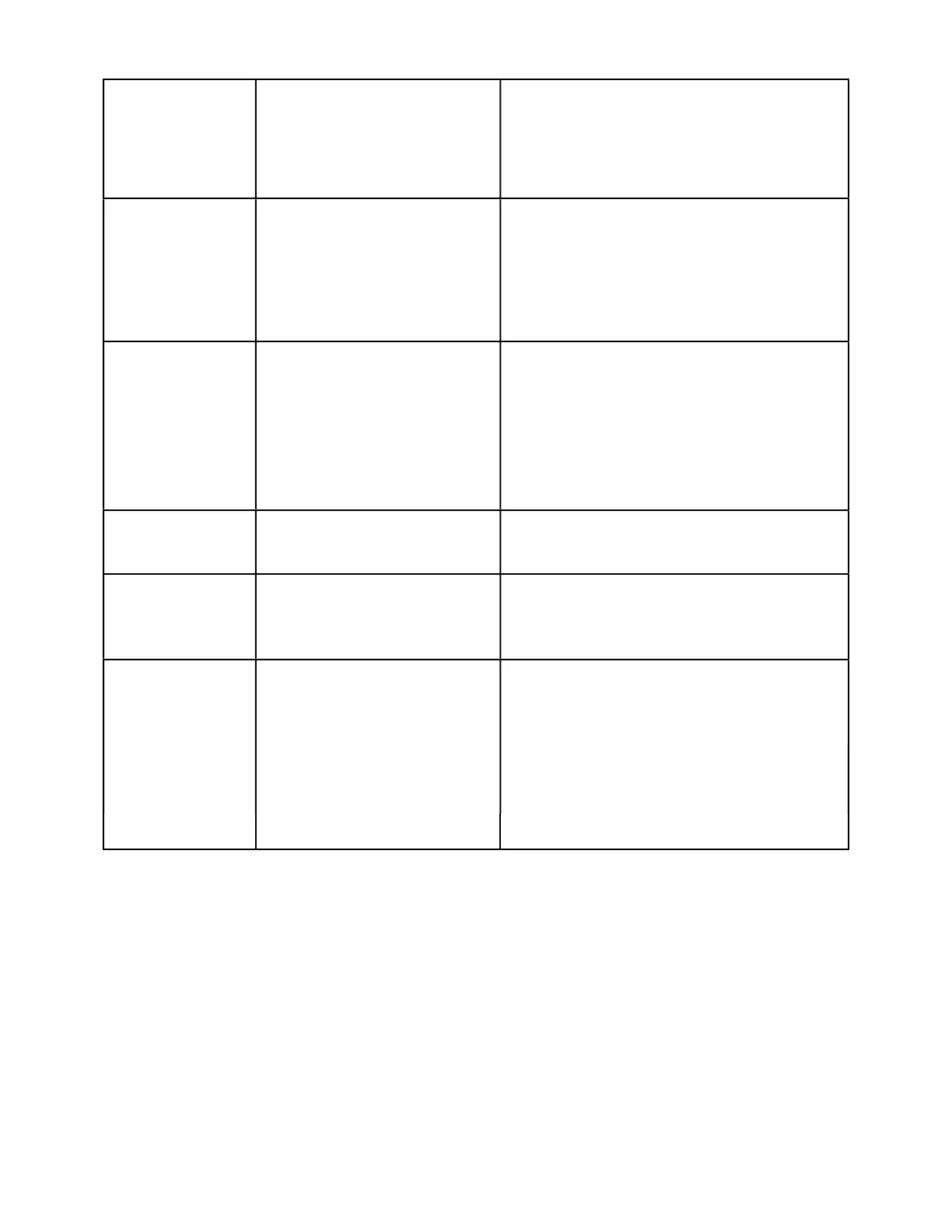

Bag sticks to PTFE

or pressure

(rubber) bar

1. Seal temp. too high

2. Seal time too high

3. PTFE in poor condition

4. Rubber is dirty /

contaminated

1. Decrease temp in bag setup screen

2. Decrease seal time in bag setup

screen

3. Turn / replace PTFE

4. Clean / replace pressure bar rubber

Bag does not tear

off

completely

1. Bag slipping through rollers

2. Compression pressure

insufficient

3. Drive roller not reversing

4. Bag did not index properly

5. Seal rubber dirty / worn

1. Clean upper and lower rollers with

alcohol to remove slip and dirt build-up

2. Adjust roller compression

3. Check tear off cylinder

4. Index another bag for test

5. Clean/ replace rubber

Two bags index

from rollers

1. Bag is folded over

2. Perf sensor dirty / damaged

3. Perf sensitivity out of

adjustment

4. Ungrounded outlet causing

electrical noise

5. Auxiliary equipment - noise

6. Seal point value too high

1. Lower inner frame and straighten bag

2. Clean / replace perf sensor

3. Contact APPI for perf adj.

4. Plug into "clean" power source

5. Contact APPI for solution

6. Set value lower

Bag does not

completely index

1. Perf is sensing hole in bag

(vent)

2. Seal position setting too low

1. Reposition bag

2. Increase seal position in bag setup screen

Bag web indexing

to

floor level without

stopping on bag

1. Perf Sensor not sensing bag

2. Dirty / damaged sensor

3. Perf sensor out of adjustment

2. Clean / replace sensor 1 & 3. Contact

APPI for adjustment

Bags web breaking

prematurely in

machine

1. Improper web tension

2. Web dragging foreign objects

3. Bag roll side-plates bent

inward

1. Adjust tension

2. Remove obstructions

3. Repair / remove side-plates

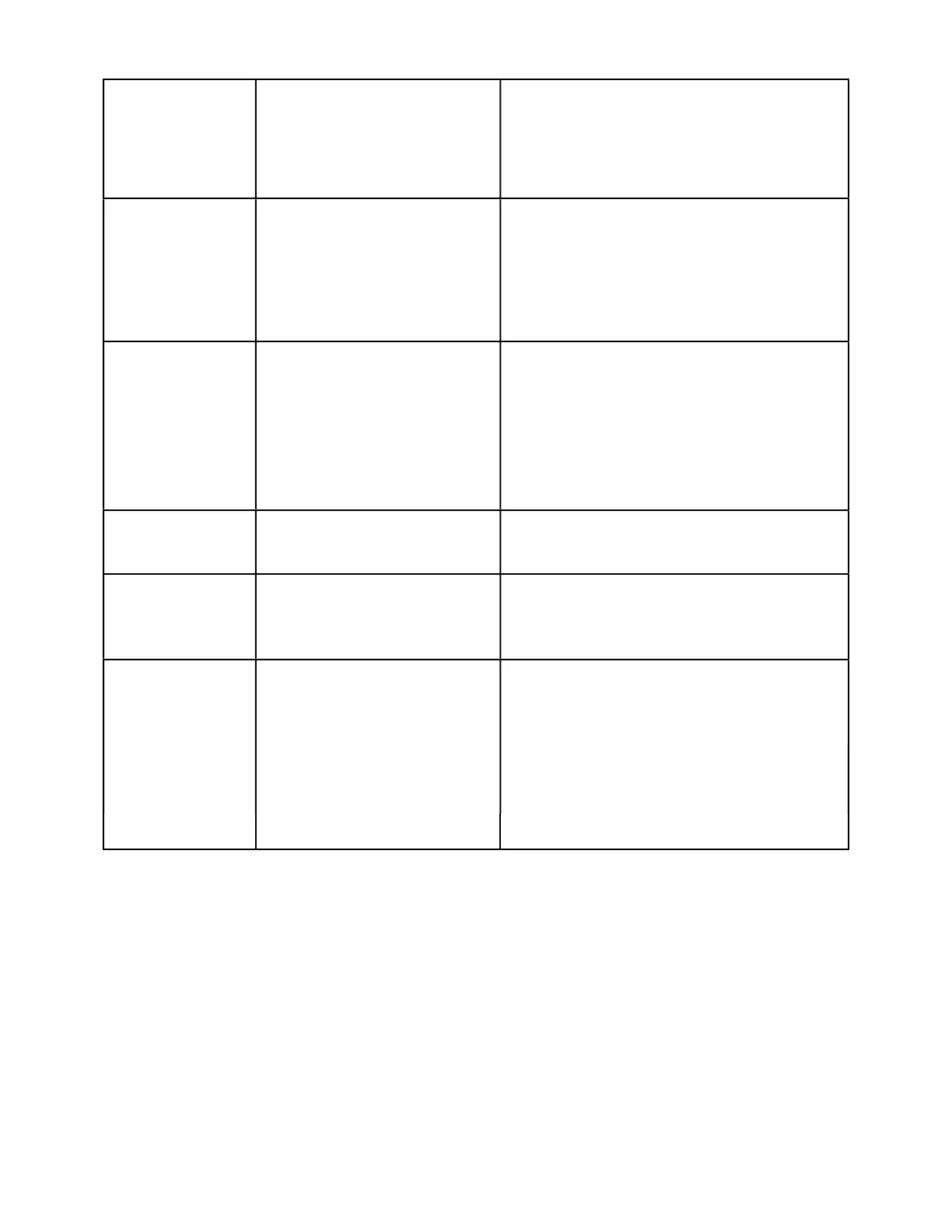

7.3 Interface PCB Voltage Table by Terminal Number

The following chart is provided to assist in further trouble shooting the T-1000.

133

Loading...

Loading...