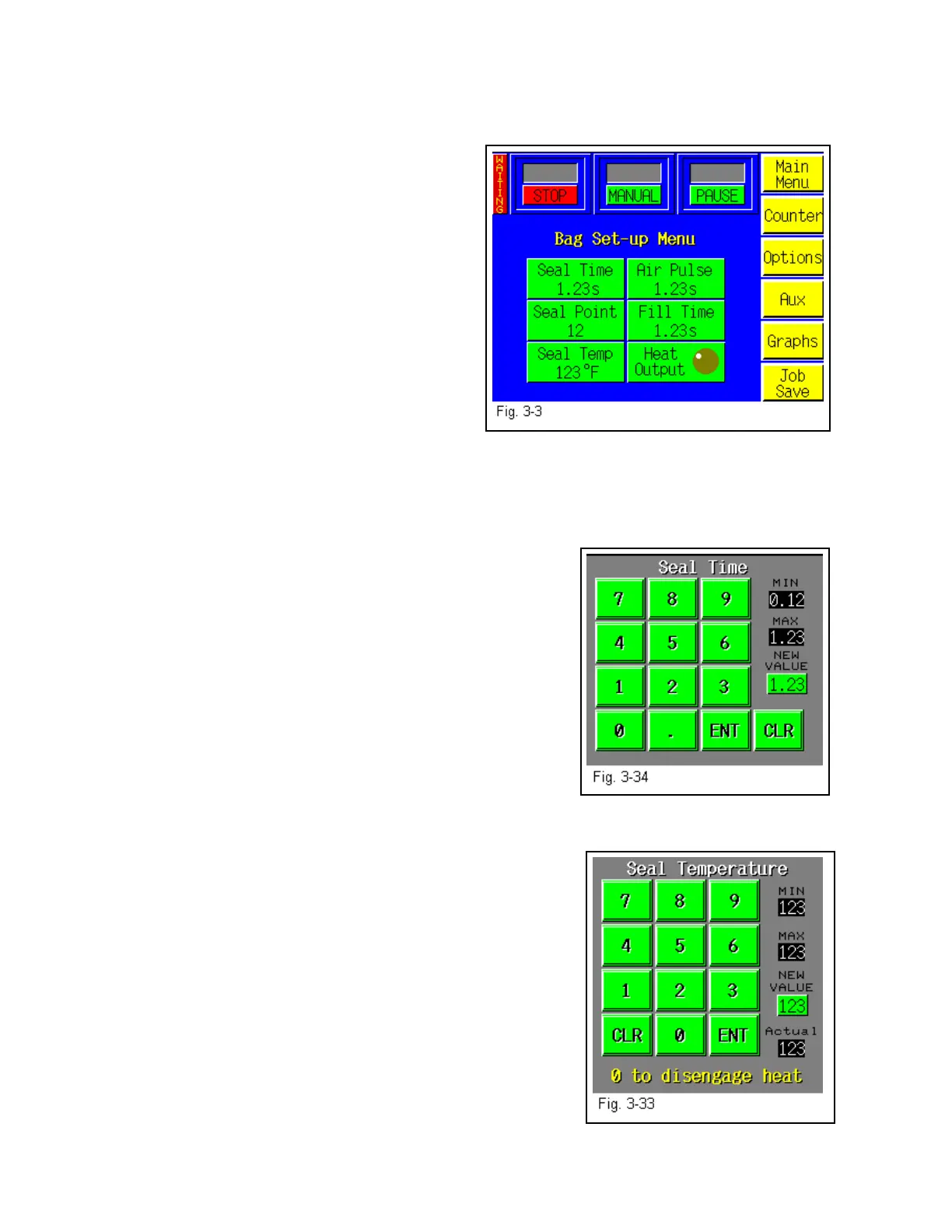

3.8 Bag Setup Menu

The Bag Set Up Menu prompts the operator to input bag timer settings which change seal point,

temperature, fill time (paced rate) and air pulse

time. Bag thickness, length, width and product

characteristics affect these settings. Once set, the

operator may save the bag settings along with

options settings and auxiliary settings for later

recall (Fig. 3-3).

The bag set up menu is the menu where most

entries and machine operation setting will occur.

When a new bag size or thickness is introduced,

the T-1000 must be set up to properly run the

bags

.

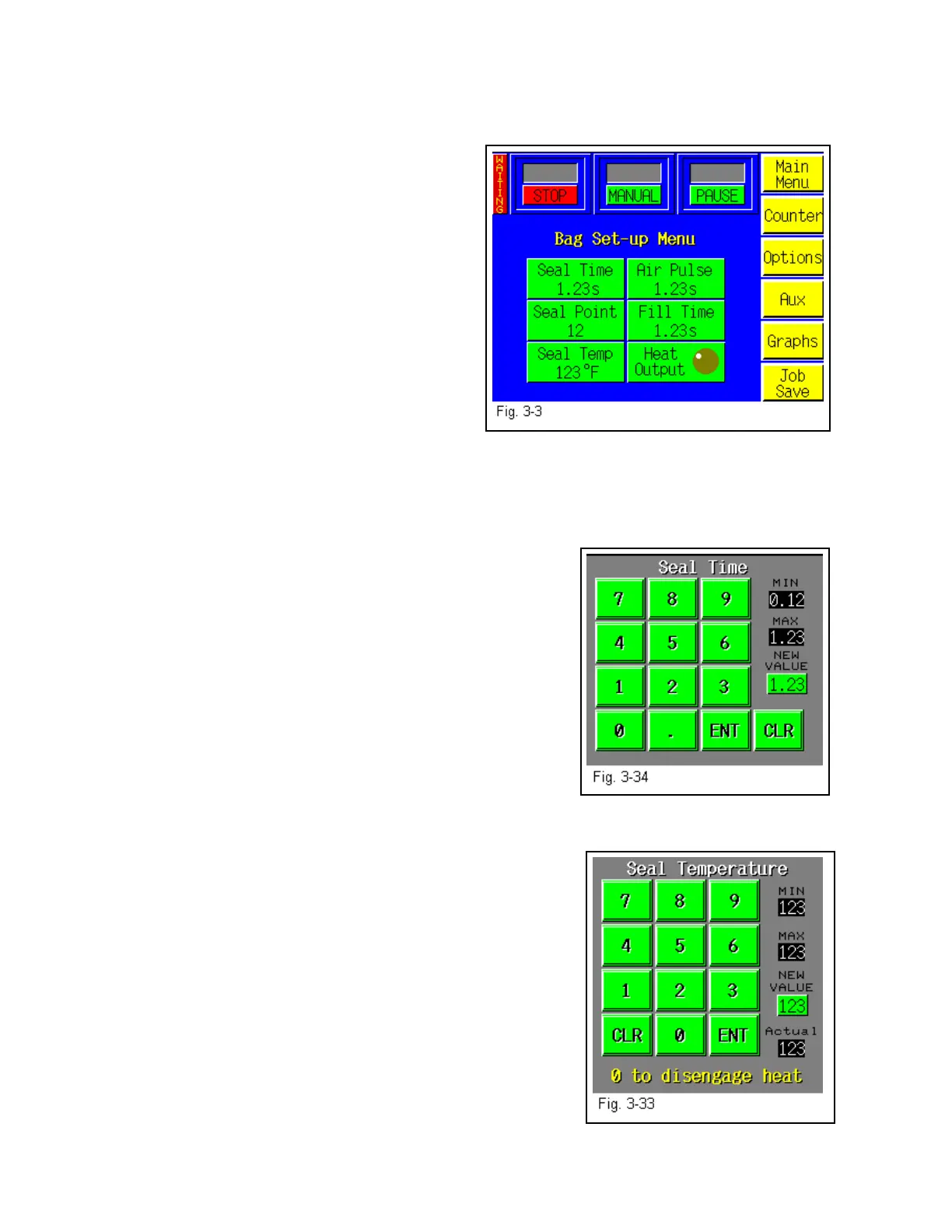

3.9 Seal Time

Displays, in seconds, the time the pressure (rubber) bar will remain touching the surface of the

bag for proper sealing. Sometimes referred to as "dwell time", seal time is one of three critical

components to obtain a strong seal (other critical factors include seal temperature and seal

pressure). To adjust the Seal Time value, touch the

highlighted <Seal Time> menu option to display a number

pad. To change the setting, press the number (decimal point

first, if less than 1) and then press <Enter>. To clear an

incorrectly pressed value, press the highlighted <Clear>

button and retype the correct value. Pressing <Enter> will

return you to the Bag Setup Screen. Test and further adjust if

necessary. See Fig. 3-34.

3.10 Seal Temperature

When the power is ON, the heater bar element receives

electrical current. The PLC pulses electrical current to the

element until the temperature setting is reached. Shorter pulses indicate maintaining the

temperature. An amber indicator lamp illuminates on the Bag

Setup Screen while the element is receiving current. The

longer the light is illuminating, the longer the "pulse" of

current and the further away from the temperature setting. If

the temperature of the heater bar is not within 10% of the set

point, “Waiting” will be flashed on the top left screen. To

adjust the value, press the highlighted <Seal Temp> button to

display the number keypad popup screen. Enter the value and

press <Enter> to return to the Bag Setup Menu. See Fig.

3-33.

NOTE: After making adjustments, test the seal strength prior

to beginning production. It is normal for the indicator light to

illuminate (pulse) during operation. As the actual

temperature approaches the set temperature, the pulses will

get shorter and shorter. When the heater bar is up to temperature, the Waiting LED indicator

32

Loading...

Loading...