3.20 Inline Printer

A Printer option is not included in the standard T-1000 package and must be purchased

separately. Used for product identification, a Printer option prints information, graphic images

or bar codes directly to the surface of the film.

APPI offers two printers as an option: 1) Thermal Inline

Transfer Printer - prints text, graphics and bar codes,

formatted in a separate software program. The label

formats, saved in a database structure can be recalled and

"downloaded" to the printer. 2) Hot Stamp Printer - prints

text (part numbers, date codes, lot numbers, etc.).

Individual characters are placed onto a "grooved plate"

which, when heated will transfer the ink (ribbon) directly

onto the bag. Also, magnetic plates are offered.

Both the Thermal and Hot Stamp printers use ribbon (foil) to transfer ink to the surface of the

bag. To enable Printer operation on the Thermal Transfer (TT) Printer, press the highlighted

Printer button.

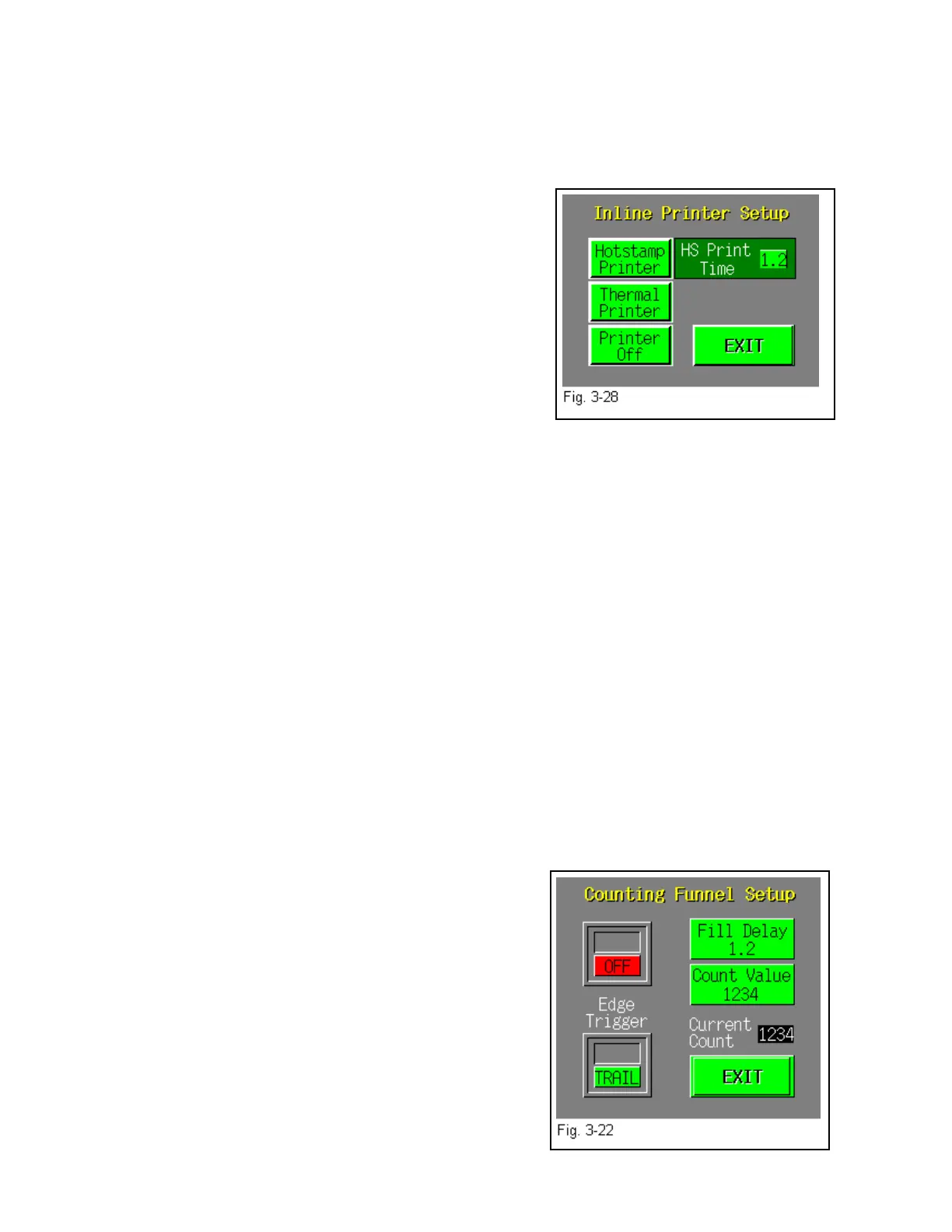

Press the highlighted Hot Stamp (HS) Printer button to enable operation of that Printer and press

Printer Off to disable the operation of the printer. See Fig. 3-28.

If the HS Printer button is pressed, a secondary setup screen will automatically appear for further

settings. To enhance text/graphics print quality, adjust the Print Time (time, in seconds that the

ribbon will be stamped on the bag) until required print quality is met. Press <EXIT> when

finished.

3.21 Counting Funnel

The Counting Funnel option is not included in the standard T-1000 package and must be

purchased separately. Used to count products entering the bag, the counting funnel may operate

in conjunction with the Accumulating Funnel to load a predetermined number of a product into

the bag, manually fed or automatically fed. Products fed into the funnel from a vibratory bowl or

infeed conveyor can be counted while entering the bag or while being collected in the

accumulating funnel. Various infrared "eyes" are available which will "see" even the smallest of

parts. The Eye typically mounts to the top of the funnel seeing the product as it enters the

funnel. Once the preset count is reached, the product is loaded and the bag is sealed and torn off

automatically. Once another bag is in position, the Eye

continues to detect product entering the bag or funnel.

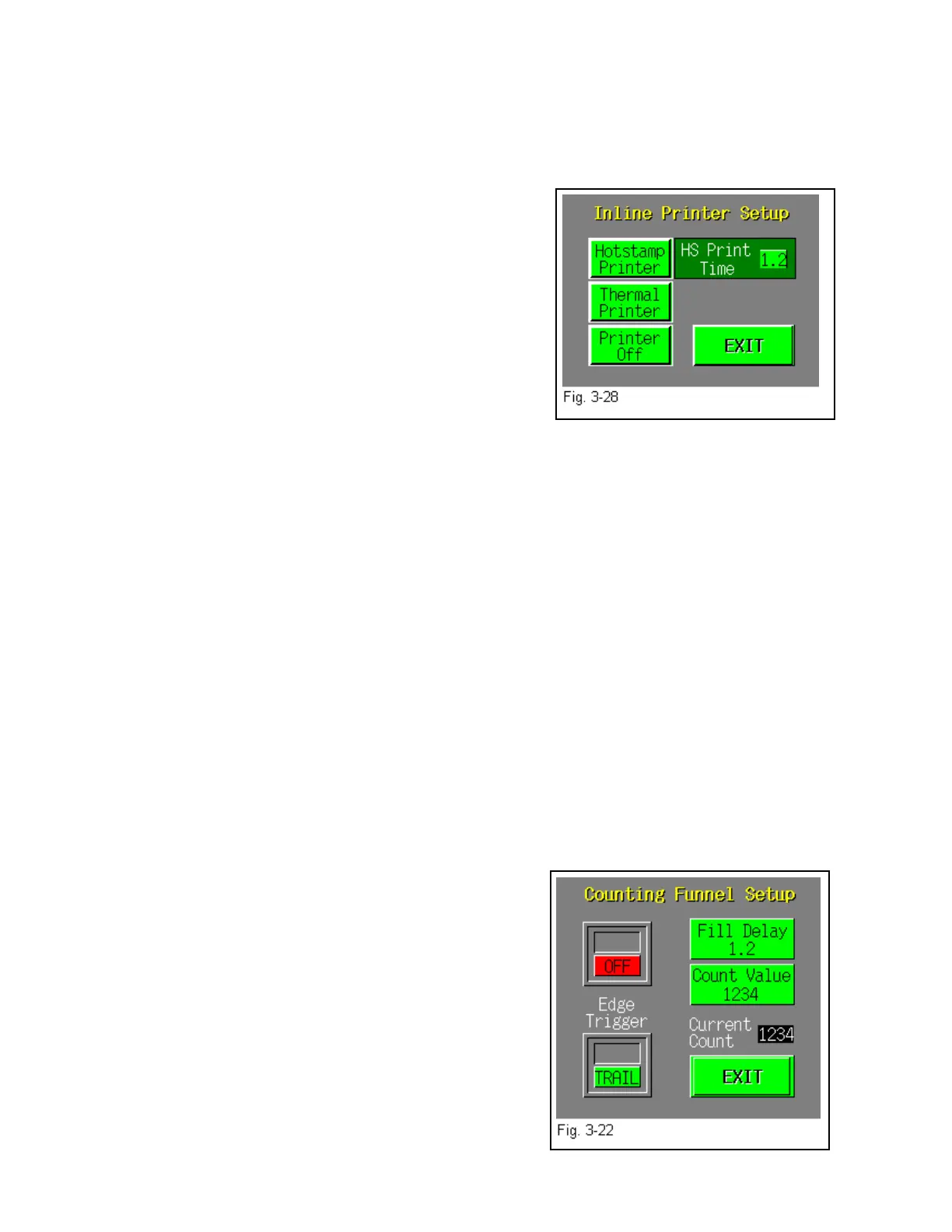

To turn the Counting Funnel ON, press the <Count

Funnel> menu option to bring up the Counting Funnel

Setup screen. The Fill Delay setting is the amount of time

between the point the final count is reached and the

bagger begins the seal operation. To adjust the Fill Delay

value, press the <Fill Delay> button, then use the key pad

to type in the number of parts to be counted. Set the value

of parts to be counted by pressing the <Count Value>

button. See Fig. 3-22.

38

Loading...

Loading...