INSPY. 1003. 4138305_03

11

over time.

Acoustic protection cover

(2)

Standard on all the NS versions, it consists

of a compartment in very thick steel sheet

and insulated entirely with soundproofi ng

material. It permits the acoustic power

emitted by the unit to be reduced and

furthermore protects the compressors from

the atmospheric agents.

4.3. HYDRAULIC COMPONENTS

Circulation pump No. 1/2 for optional

circuit configurator

Depending on the characteristics of the

pump chosen, it offers a useful head to

overcome the pressure drops in the system.

Whenever the reserve pump is present, this

is managed by the electronic board.

Expansion tank 2 per circuit (2x25 l)

(only in the versions with pump)

membrane type with nitrogen preloading.

4.4. SAFETY AND CONTROL COMPONENTS

Differential pressure switch IP54 1 per circuit

Located between the inlet and outlet of

the evaporator, it has the task of checking

that there is water circulation; otherwise,

the unit blocks.

Low pressure transducer

Allows displaying, on the microprocessor

card display, the value of the compressor's

suction pressure (one per circuit) on the

low-pressure side of the refrigerant circuit

High pressure transducer

Allows displaying, on the microprocessor

card display, the value of the compressor's

delivery pressure (one per circuit) On the

high pressure side of the refrigerant circuit

Double high pressure switch (manual + tool)

Factory-calibrated, it is placed on the high

pressure side of the cooling circuit, it shuts

down compressor operation in the case of

abnormal operating pressure.

Refrigeration circuit safety valves (HP, LP)

Calibrated at 22 bar HP - 16.5 LP, they cut

in relieving the overpressure in the case of

abnormal operating pressures.

− Fuses or thermomagnetic switches for

compressors protection to be specified

when ordered

− Fan protection thermomagnetic switch

− Secondary thermomagnetic switch

protection

4.5. ELECTRICAL COMPONENTS

Electrical panel

Contains the power section and the

management of the controls and safety

devices.

Door-block disconnecting switch

IT is possible to access the electrical panel

by disconnecting the voltage, then using

the opening lever of the panel itself. This

lever can be blocked with one or more

padlocks during maintenance, in order to

prevent the machine being powered up

accidentally.

Control keypad

Provides full control functions.

NB

For a detailed description refer to the user

manual.

Remote control panel (PVR3)

This allows the chiller command operations

to be given from a distance.

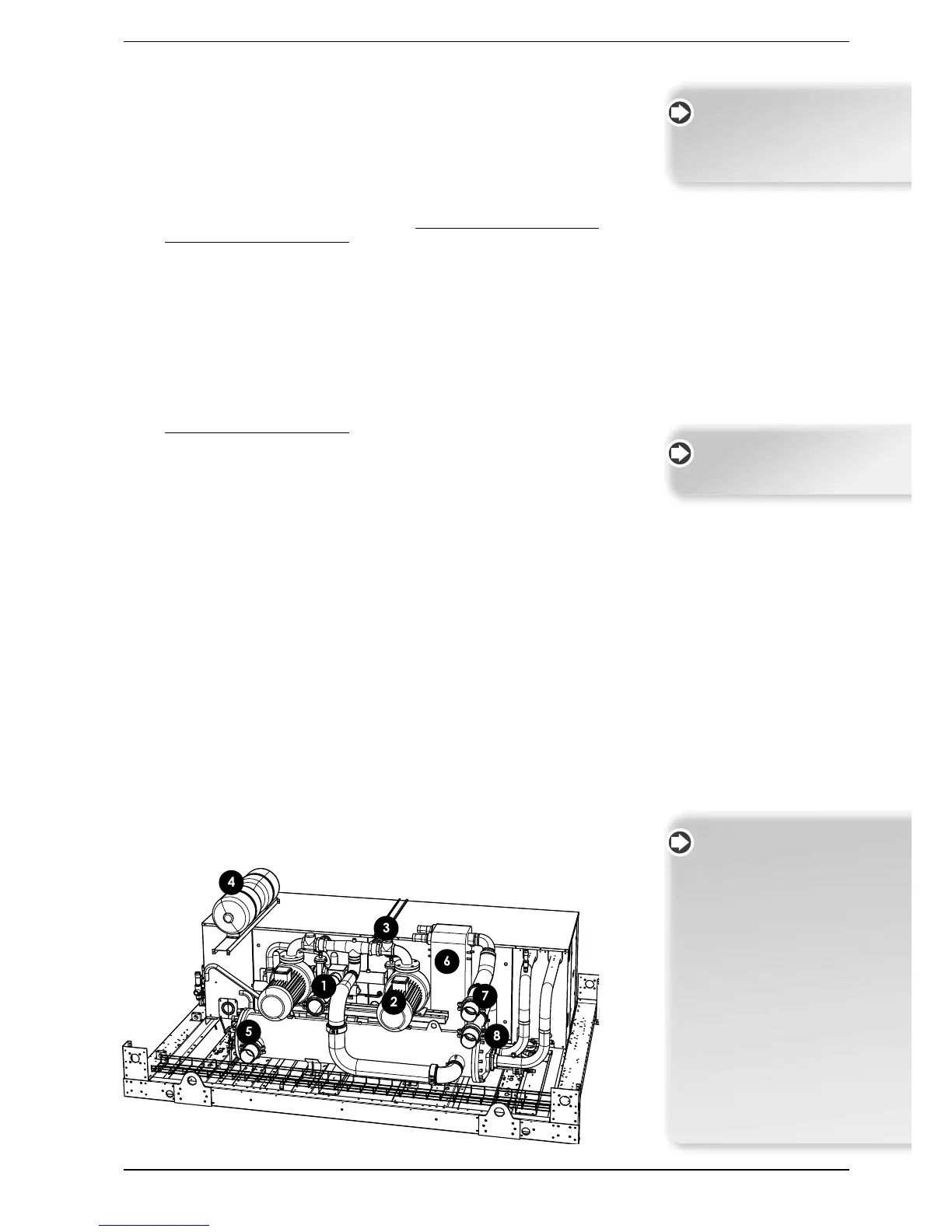

Pump version (example)

(2) IT IS POSSIBLE TO HAVE A FUR-

THER NOISE REDUCTION, WITH

DCPX AND AK ACCESSORIES.

For further information refer to

the chapter ACCESSORIES.

HYDRAULIC CIRCUIT KEY:

1. Evaporator input

2. Pump unit

3. Shut-off valves

4. Expansion tanks 2x25 litres

5. Water outlet with attachment

6. Total recovery

7. Inlet total recovery

8. Output total recovery

In any versions with or without

pumps, desuperheater and total

recovery, the water connections

are VICTAULIC with supplied joint

to weld

N.B.: the drawing is only an example

and reflects only the version with

pumps and total recovery.

All the electric cables are wired

for immediate recognition of

the electrical components

Loading...

Loading...