INSPY. 1003. 4138305_03

32

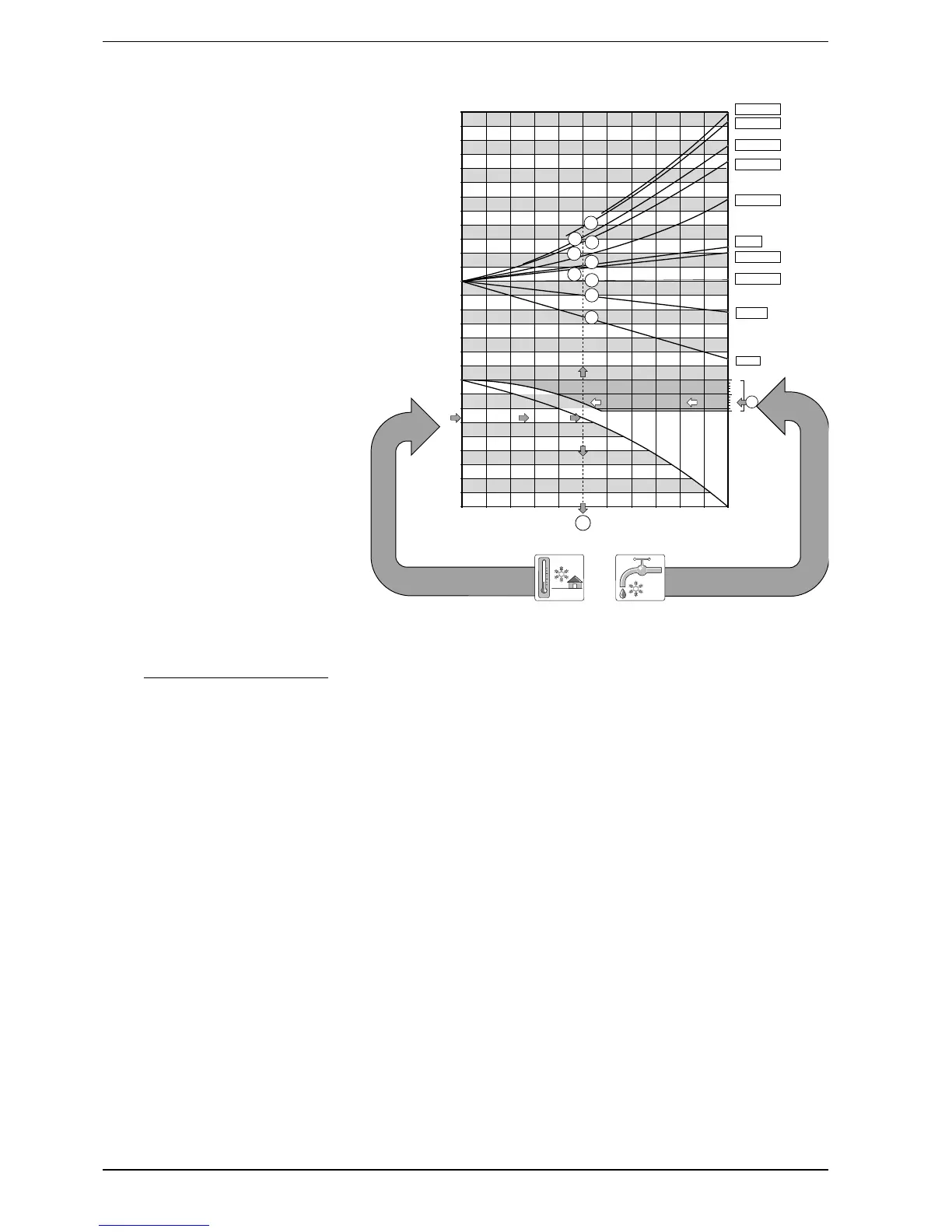

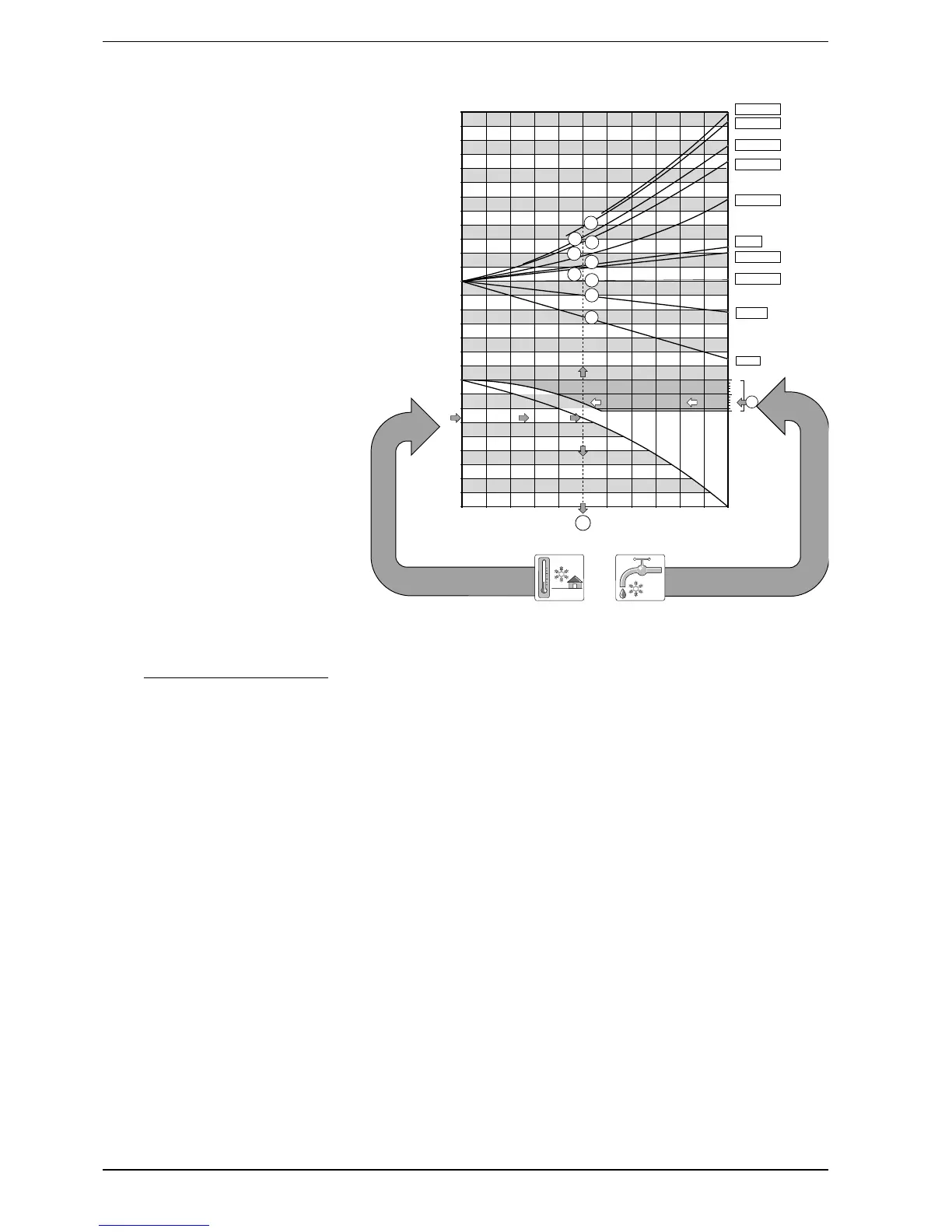

9. GLYCOL

−

The cooling capacity and input

power correction factors make al-

lowance for the presence of glycol

and the different evaporation tem-

perature.

− The pressure drop correction factor

already takes account of the dif-

ferent flow rate deriving from the

application of the water flow rate

correction factor.

− The correction factor of the water

flow rate is calculated so as to

maintain the same ∆t that would be

used in the absence of glycol.

NOTE

To make it easier to read the following

graph, an example is given.

By using the diagram below it possible

to establish the percentage of glycol

necessary; this percentage can be

calculated taking into account one of

the following factors:

On the basis of the fluid considered

(water or air), it will be necessary to en-

ter the graph from the right or left side,

from the intersection of the outside

air temperature or processed water

temperature straight lines and the rela-

tive curves, a point is obtained through

which the vertical line that will identify

both the percentage of glycol and the

relative correction coefficients will have

to pass.

9.1. HOW TO READ THE GLYCOL

CURVES

The curves shown in the figure summa-

rise a notable quantity of data, each

of which is represented by a specific

curve. In order to use these curves

correctly, it is necessary to make some

initial considerations:

− If you want to calculate the per-

centage of glycol on the basis of

the outside air temperature, you

must enter from the left-hand axis

and, once you have intersected

the curve, trace a vertical line

which, in turn, will intercept all the

other curves; the points obtained

from the upper curves represent the

coefficients for the correction of the

cooling capacity and input power,

for the flow rates and the pressure

drops (remember that these coef-

ficients must anyway be multiplied

by the rated value of the sizes ex-

amined); the lower axis advises the

percentage of glycol necessary on

the basis of the outside air tempera-

ture considered.

− If you want to calculate the percent-

age of glycol on the basis of the

temperature of the processed water,

you must enter from the right-hand

axis and, once you have intersected

the curve, trace a vertical line which,

in turn, will intercept all the other

curves; the points obtained from the

upper curves represent the coef-

ficients for the cooling capacity

and input power, for the flow rates

and the pressure drops (remember

that these coefficients must anyway

be multiplied by the rated value of

the sizes examined); the lower axis

advises the percentage of glycol

necessary to produce water at the

required temperature.

− Remember that the initial sizes “OUT-

SIDE AIR TEMPERATURE” and “PROC-

ESSED WATER TEMPERATURE”, are not

directly linked to each other, so it is

not possible to enter the curve of one

of these sizes, and obtain the cor-

responding point on the other curve.

KEY:

FcGPf Correction factor of the cooling capacity

FcGPa Correction factor of the input power

FcGDpF (a) Correction factor of the pressure drops (evaporator) (average temp. = -3.5°C)

FcGDpF (b) Correction factor of the pressure drops (average temp. = 0.5°C)

FcGDpF (c) Correction factor of the pressure drops (average temp. = 5.5°C)

FcGDpF (d) Correction factor of the pressure drops (average temp. = 9.5°C)

FcGDpF (e) Correction factor of the pressure drops (average temp. = 47.5°C)

FcGQF Correction factor of the outputs (evaporator) (average temp. = 9.5°C)

FcGQC Correction factor of the outputs (condenser) (average temp. = 47.5°C)

NB:

Although the graph reaches outside air temperatures of -40°C, it is necessary to maintain the machine's

operating limits as reference.

Loading...

Loading...