7. MAINTENANCE

Always carry out maintenance operations when the machine is still and after having removed the key

from the control panel with the platform in rest position.

The maintenance operations described below refer to a machine with ordinary working use. In case of

difficult conditions of use (extreme temperatures, corrosive environments, etc.) or following long

machine inactivity, it will be necessary to contact the AIRO assistance service to change the

intervention schedule.

Repairs and maintenance operations are to be carried out by trained and authorised personnel only. All

maintenance operations should be carried out in compliance with the current work safety regulations

(work places, personal protection equipment, etc...).

Carry out only the maintenance and adjustment operations described in this user manual. If necessary

when replacing parts contact our technical support only.

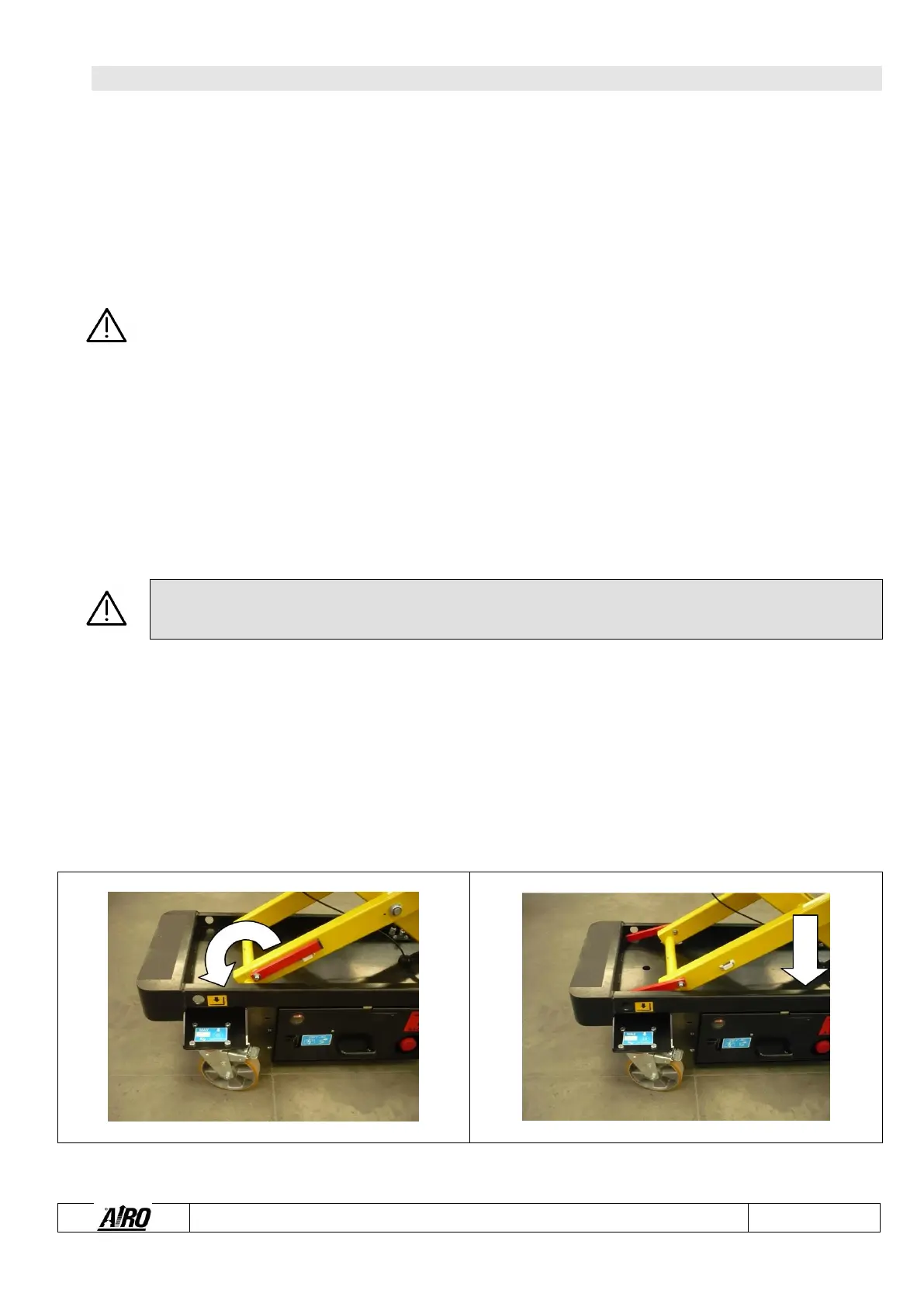

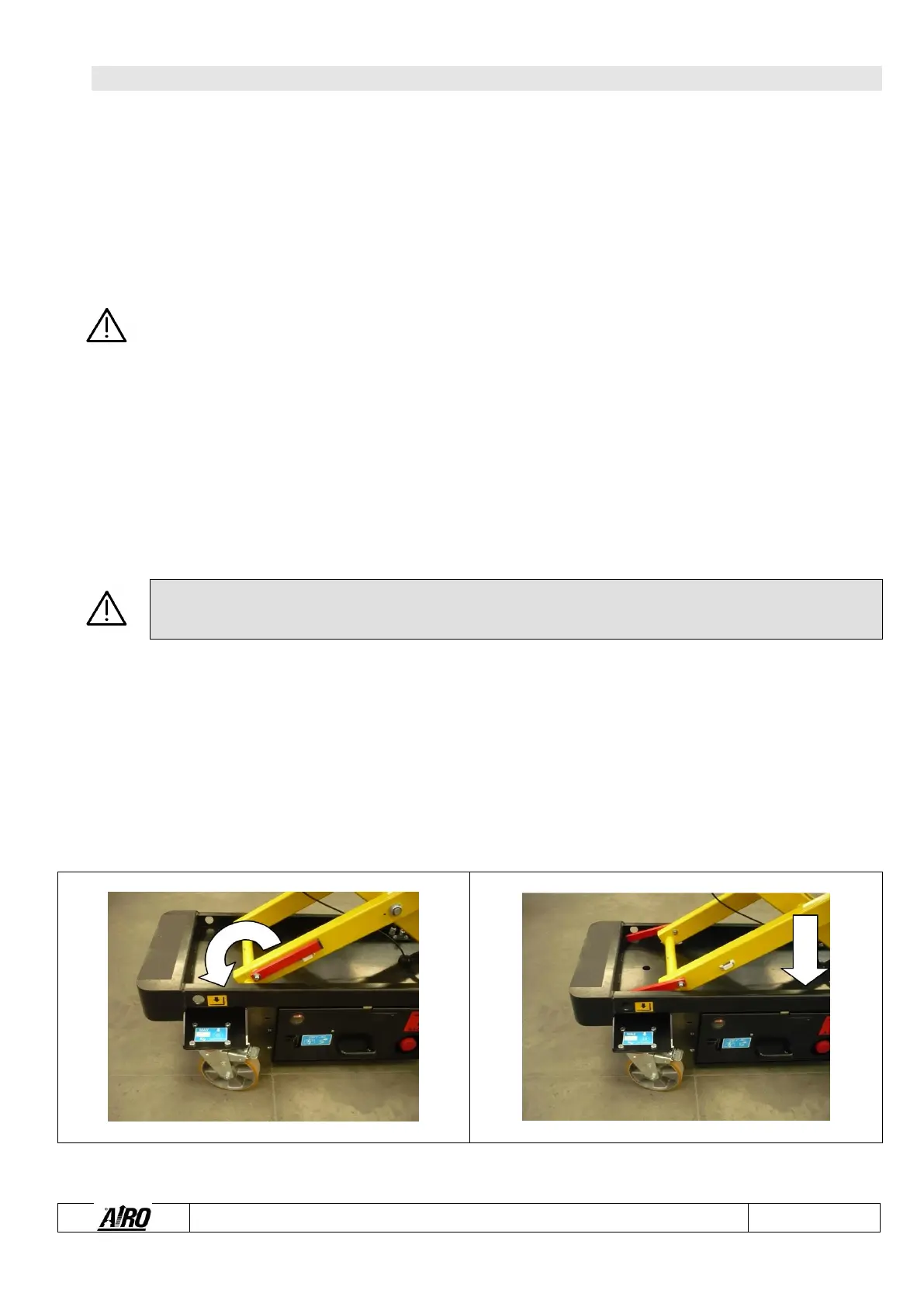

During interventions, check that the machine is completely locked. Before carrying out maintenance

operations inside the lifting structure, check that this is off-line in order to avoid accidental lowering of

the booms (chapter "Safety stop for maintenance").

Remove the battery cables and provide batteries with a suitable protection during welding operations.

In case of replacement, use original spare parts only or spare parts approved by the manufacturer.

Disconnect the 110/230V AC and/or 380V AC sockets, if any.

The lubricants, hydraulic oils, electrolytes and all detergent products should be handled with care and

disposed of in safety according to the current regulations. A prolonged contact with the skin may

cause irritations and dermatosis; wash with water and soap and rinse thoroughly.

Contact with eyes, especially with electrolytes, is also dangerous; rinse with water thoroughly and call

the doctor.

the raised position.

Loading...

Loading...