WARNING!

Usually the inclinometer does not need to be adjusted unless the electronic control unit is replaced. The

equipment necessary for the replacement and adjustment of this component is such that these operations

should be carried out by skilled personnel.

AS THIS OPERATION IS VERY IMPORTANT IT IS TO BE CARRIED OUT BY SPECIALIZED TECHNICIANS

ONLY.

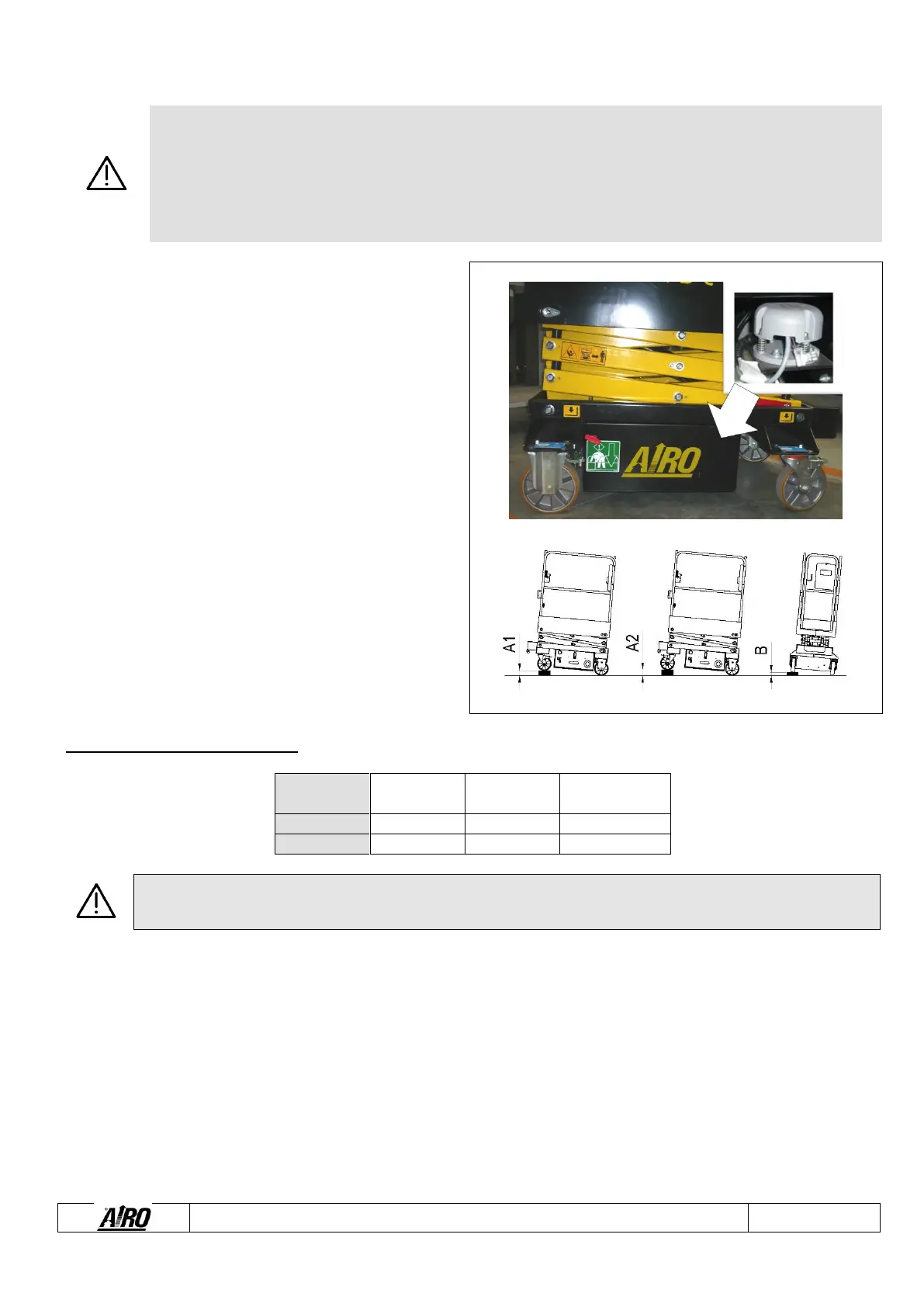

The inclinometer (see figure aside) does not require any

adjustment since it is calibrated in the factory before the

machine is delivered.

This device is located on the chassis and controls the chassis

inclination. If the chassis is inclined beyond the allowed:

1) It disables lifting.

2) It signals the instability condition through the alarm

(see “Use instructions”).

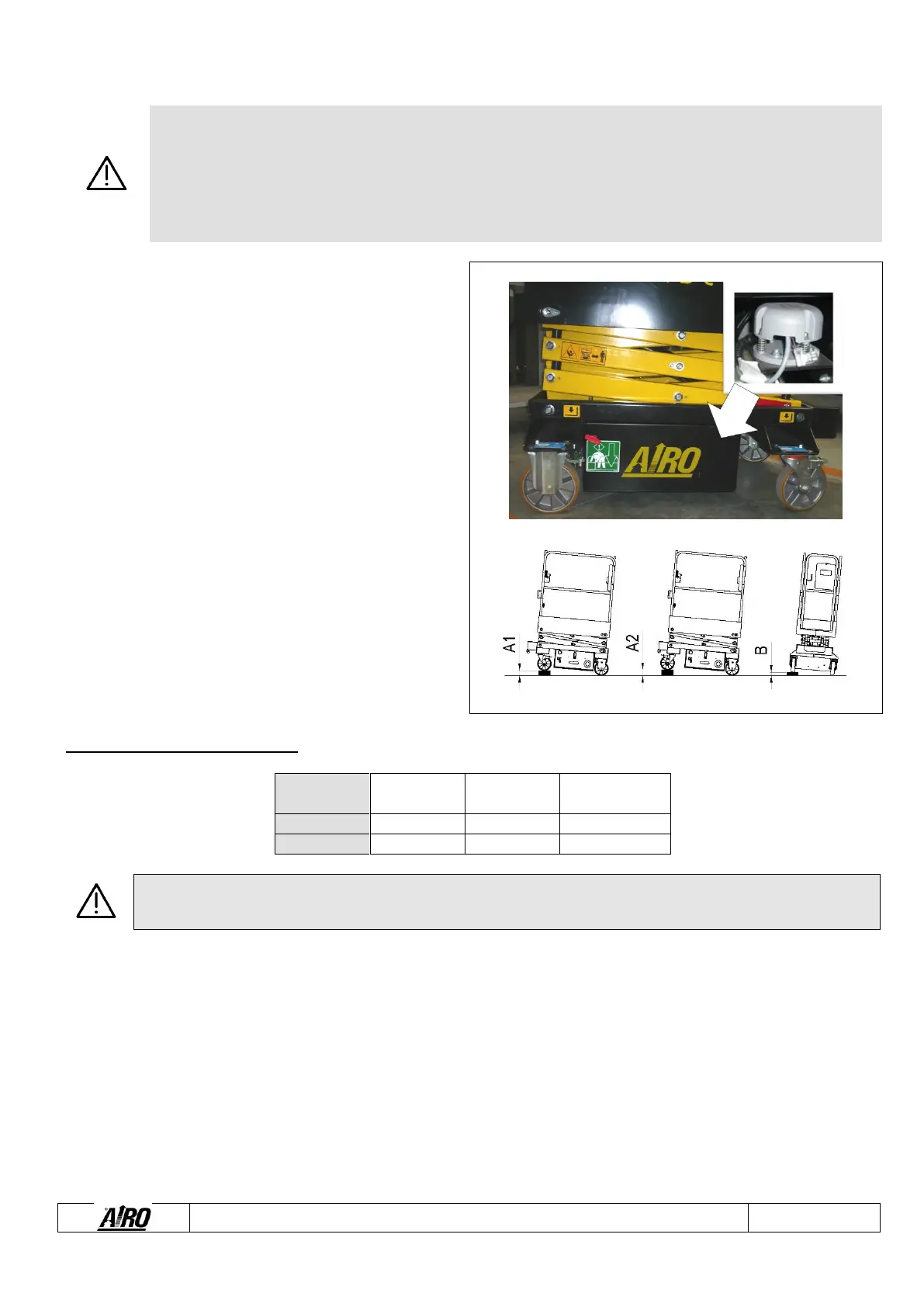

The inclinometer checks the inclination with respect to the two

axes (X; Y). On machine models that have the same

transversal and longitudinal inclination limits, the control is

carried out with reference to one axis only (X-axis).

To adjust the inclinometer according to the transversal axis

(normally X-axis):

Set the machine so as to place a shim of dimension (B+5

mm) under the two side right or left wheels (see following

table).

Wait three seconds (intervention delay set at factory) until

the audible alarm turns on;

If the alarm does not go off CALL THE TECHNICAL

ASSISTANCE.

WARNING! The dimensions of shims A1, A2 and B refer to max. allowed inclination as indicated in table

“TECHNICAL FEATURES”. To be used during the inclinometer calibration.

Loading...

Loading...