Use and Maintenance Manual - XP - XLP Series

7.3.3 Hydraulic circuit oil level check and change

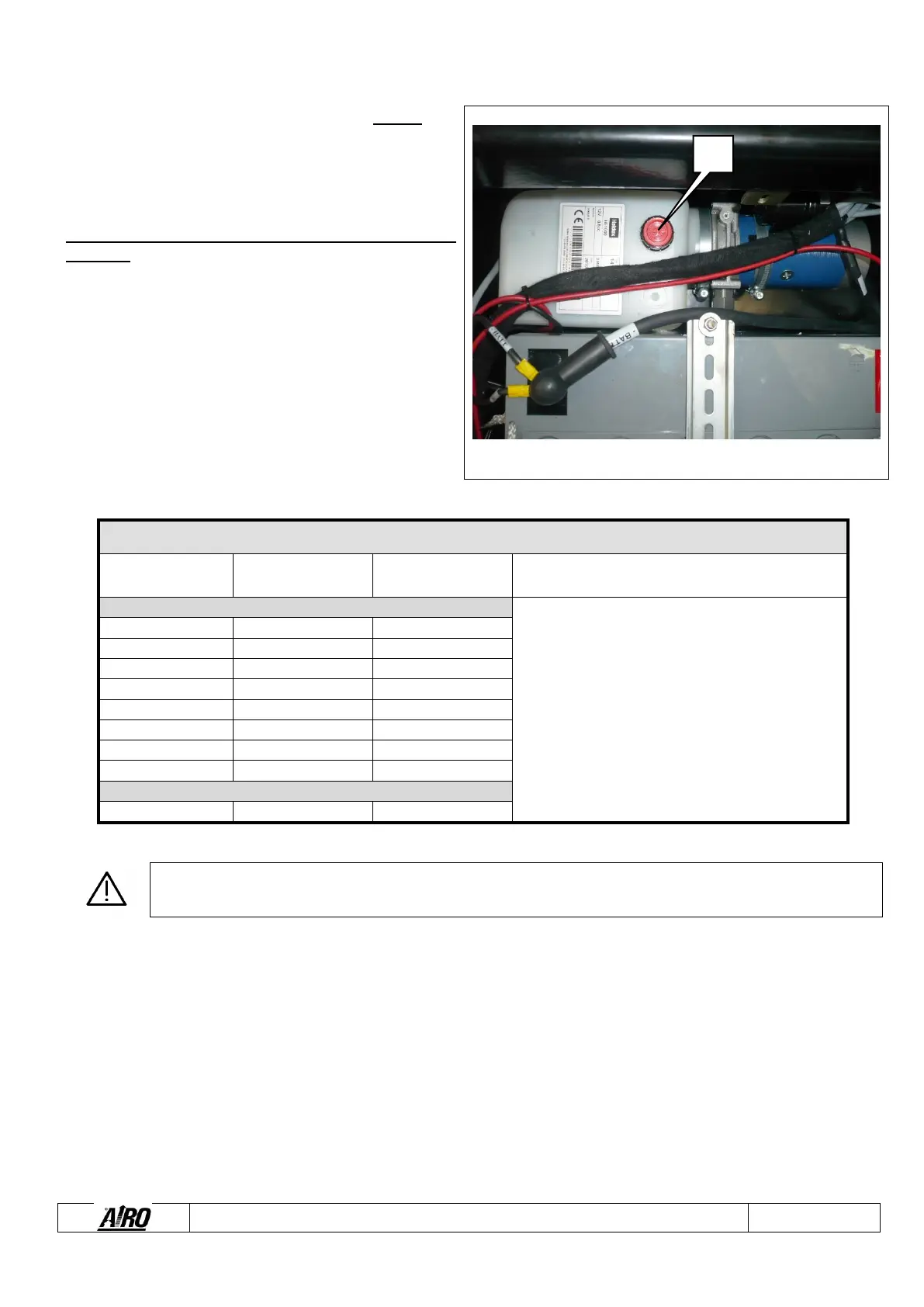

Check the level in the transparent tank at least monthly. The

level is correct because the free surface of the oil is about 5

mm below the upper wall of the tank; if necessary top up until

it reaches the maximum expected level. The oil check should

be carried out when platform is completely lowered.

Completely change the hydraulic oil of the tank at least every

two years.

To empty the tank:

- Lower the platform completely.

- Stop the machine by pressing the emergency stop button

of the ground control panel.

- By means of an external pump, suck the oil from the tank

through filler cap A.

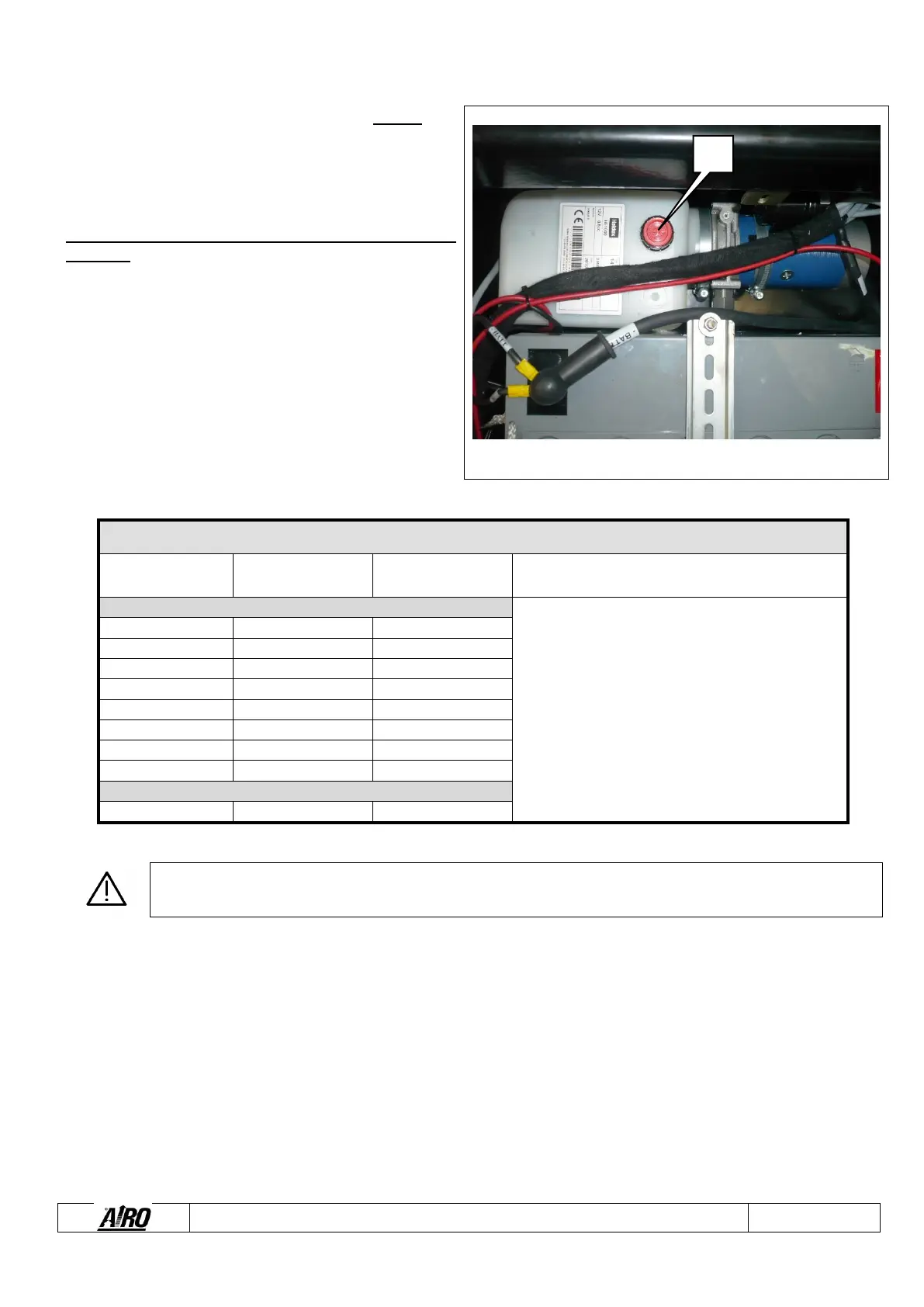

Use only the types of oil and quantity indicated in the table

below.

BIODEGRADABLE OILS - OPTIONAL

Do not dispose of used oil in the environment. Comply with the current local standards.

The lubricants, hydraulic oils, electrolytes and all detergent products should be handled with care and disposed of in safety

according to the current regulations. A prolonged contact with the skin may cause irritations and dermatosis; wash with water and

soap and rinse thoroughly. Contact with eyes, especially with electrolytes, is also dangerous; rinse with water thoroughly and call

the doctor.

Loading...

Loading...