Use and Maintenance Manual - XP - XLP Series

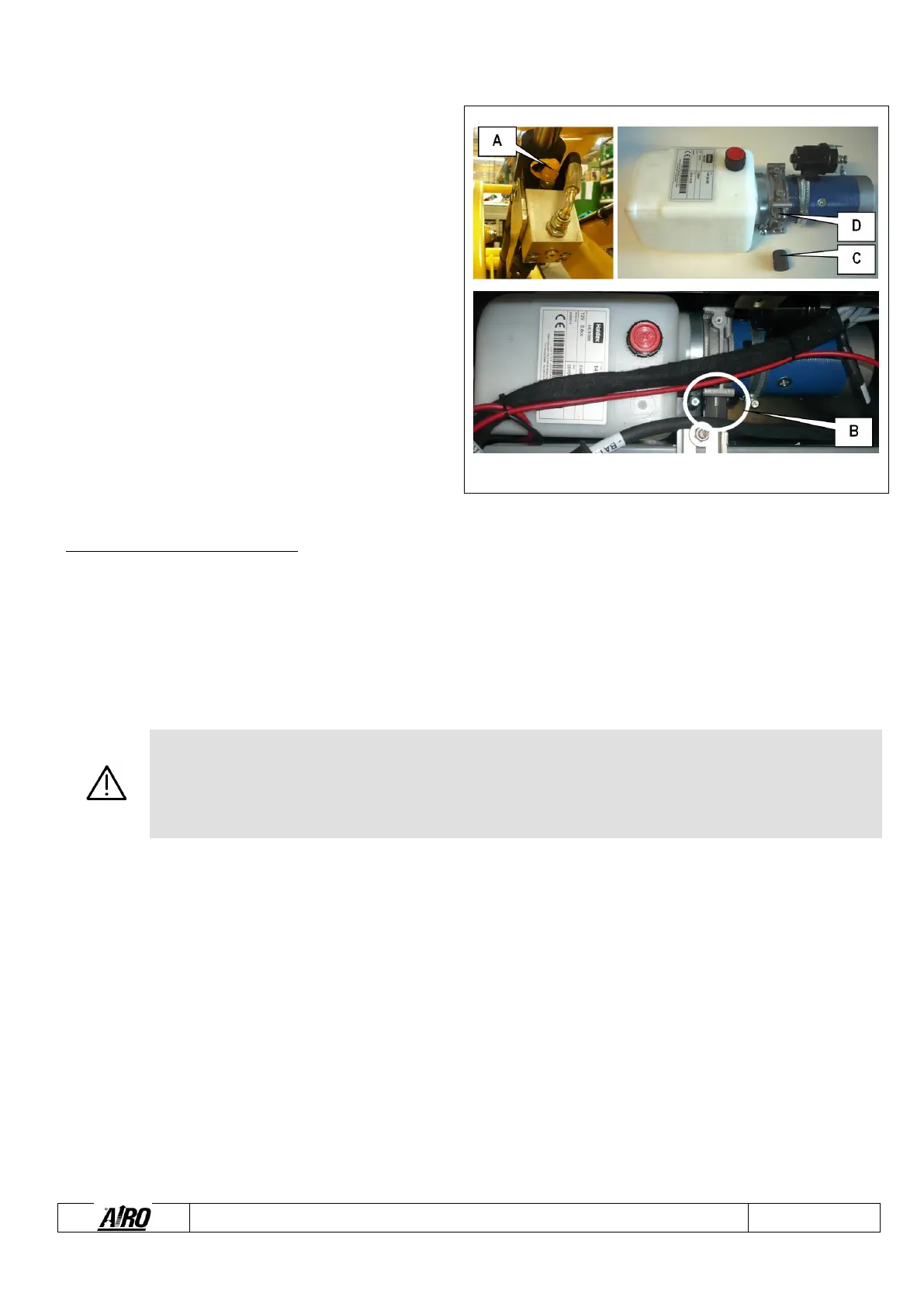

7.3.5 Pressure relief valve operation check

The self-propelled platforms, XP-XLP series, have a main

relief pressure valve on the lifting circuit to avoid dangerous

overpressure values. Normally, this valve does not require any

adjustment, since it is calibrated in the factory before the

machine is delivered.

The system needs calibration:

in case of replacement of the mini control unit

in case of replacement of the pressure relief valve only.

To check the pressure relief valve on the lifting circuit:

Introduce a pressure gauge with full scale of at least 200

bars in the special quick coupling A (1/4” BSP).

Bringing the push-button station to the ground lift the

machine up to the end stop.

Check the pressure value. The correct value is indicated in

the chapter “Technical features".

Check operation at least once a year.

To calibrate the pressure relief valve on the lifting circuit:

Introduce a pressure gauge with full scale of at least 200 bars in the special quick coupling A (1/4” BSP).

Locate the maximum pressure valve B and remove the cap C by unscrewing it;

Bringing the push-button station to the ground lift the machine up to the end stop.

Adjust the pressure relief valve by means of the adjusting screw D so as to reach the pressure value indicated in chapter

"Technical Features".

Once calibration has been carried out, lock the adjusting dowel by means of the lock-nut C.

WARNING!

AS THIS OPERATION IS VERY IMPORTANT IT IS TO BE CARRIED OUT BY SPECIALIZED TECHNICIANS

ONLY.

Loading...

Loading...