Rockwell Automation Publication 22C-IN002E-EN-P - November 2010

Chapter 5

Electrical Installation

Chapter Objectives

This chapter provides information on electrical installation of a PowerFlex

Drive Package for Fan and Pump Applications.

Power Wire Size

Requirements

Wire size should be determined based on the size of the conduit openings,

and applicable local, national and international codes such as NEC/CEC.

Power Terminal Block

Specification

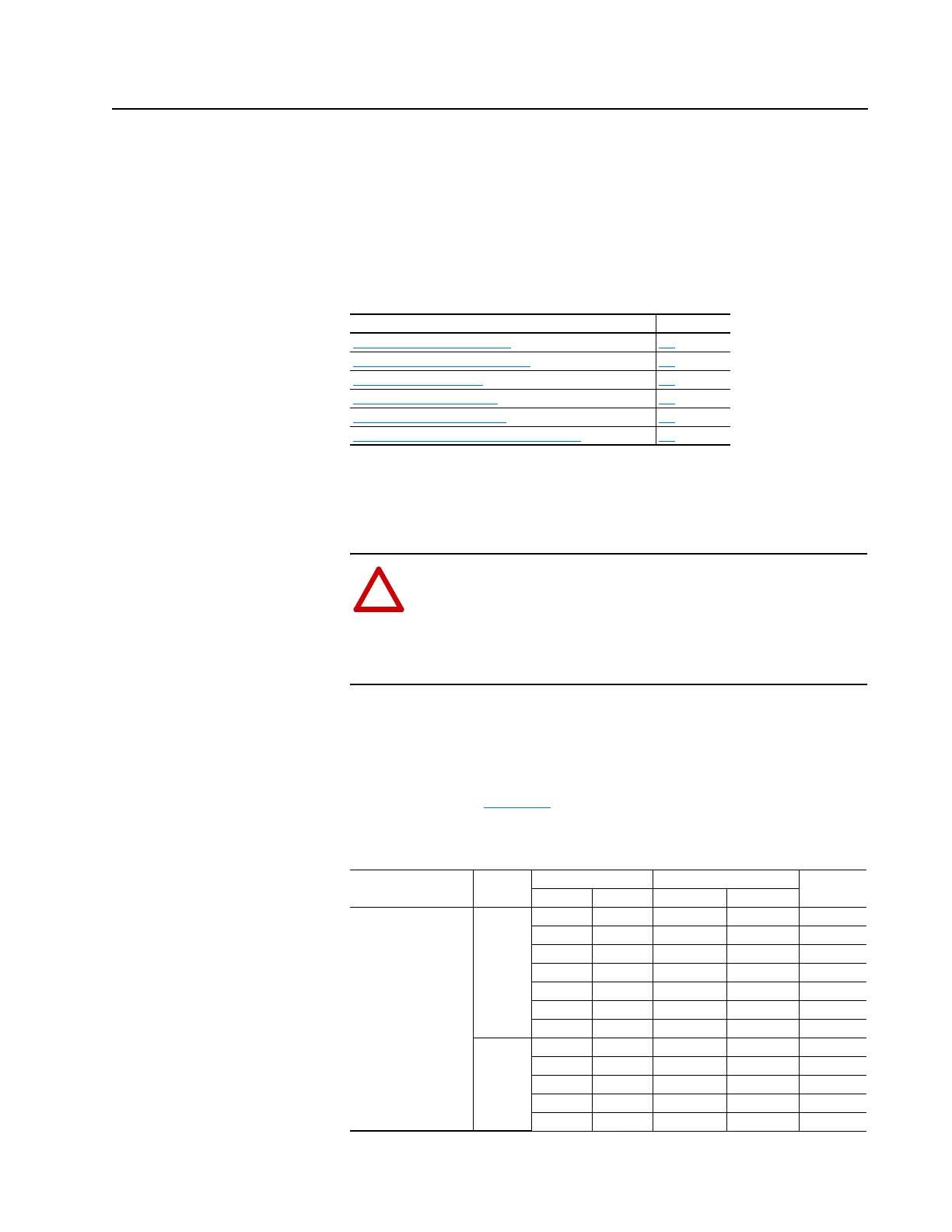

Input power wiring should be sized according to applicable codes to handle

the drive's continuous-rated input current. Output wiring should be sized

according to applicable codes to the handle the drive's continuous-rated

output current. See Table 5.A

for the range of power wire sizes that the

terminals can accommodate.

Table 5.A Power Wire Sizes

For information on . . See page

Power Wire Size Requirements

5-1

Power Terminal Block Specification 5-1

Control and Signal Wiring 5-2

Installing Input Power Wiring 5-2

Installing Output Power Wiring 5-3

Installing an Optional Transformer or Reactor 5-3

ATTENTION: National codes and standards (NEC, VDE, BSI,

etc.) and local codes outline provisions for safely installing

electrical equipment. Installation must comply with specifications

regarding wire types, conductor sizes, branch circuit protection,

and disconnect devices. Failure to do so may result in personal

injury and/or equipment damage.

Name Package

Hp Wire Size Range

Torque208V AC 480V AC Minimum Maximum

Input Power

L1(R), L2 (S), L3 (T)

A, B 3…5 1…10 14 AWG 8 AWG 12

7.5…10 15…25 14 AWG 4 AWG 35

15…20 30…50 14 AWG 2 AWG 35

25…40 60…100 6 AWG 250 MCM 275

50 125…200 (2) 1/0 350 MCM 275

– 250…300 (2) 2/0 350 MCM 275

– 350 (3) 3/0 350 MCM 275

C – 3…7.5 22 AWG 8 AWG 13

– 10…30 14 AWG 4 AWG 19

– 40 12 AWG 1/0 AWG 40

– 50…60 12 AWG 2 AWG 90

– 75…100 6 AWG 250 MCM 275

Loading...

Loading...