4-4 Mechanical Installation

Rockwell Automation Publication 22C-IN002E-EN-P - November 2010

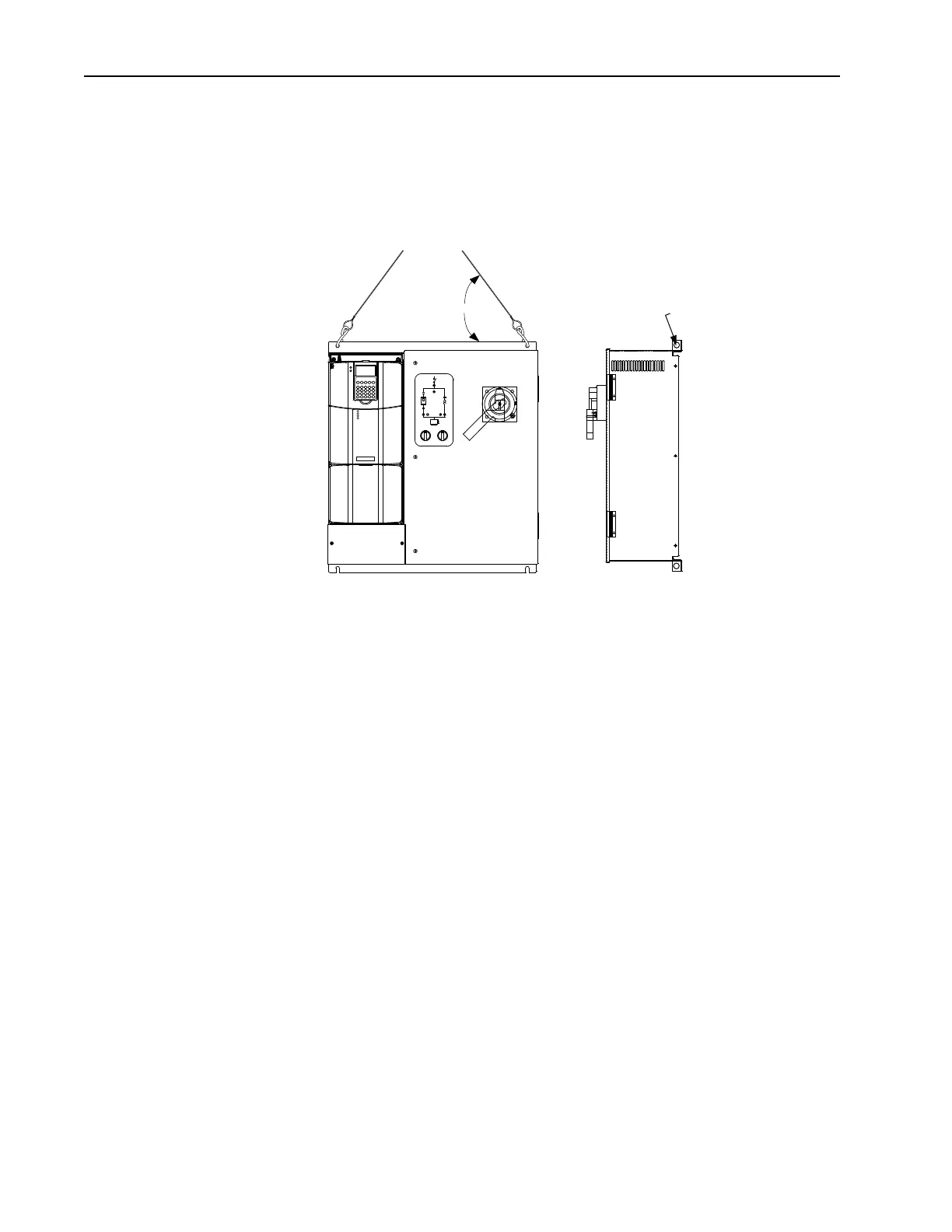

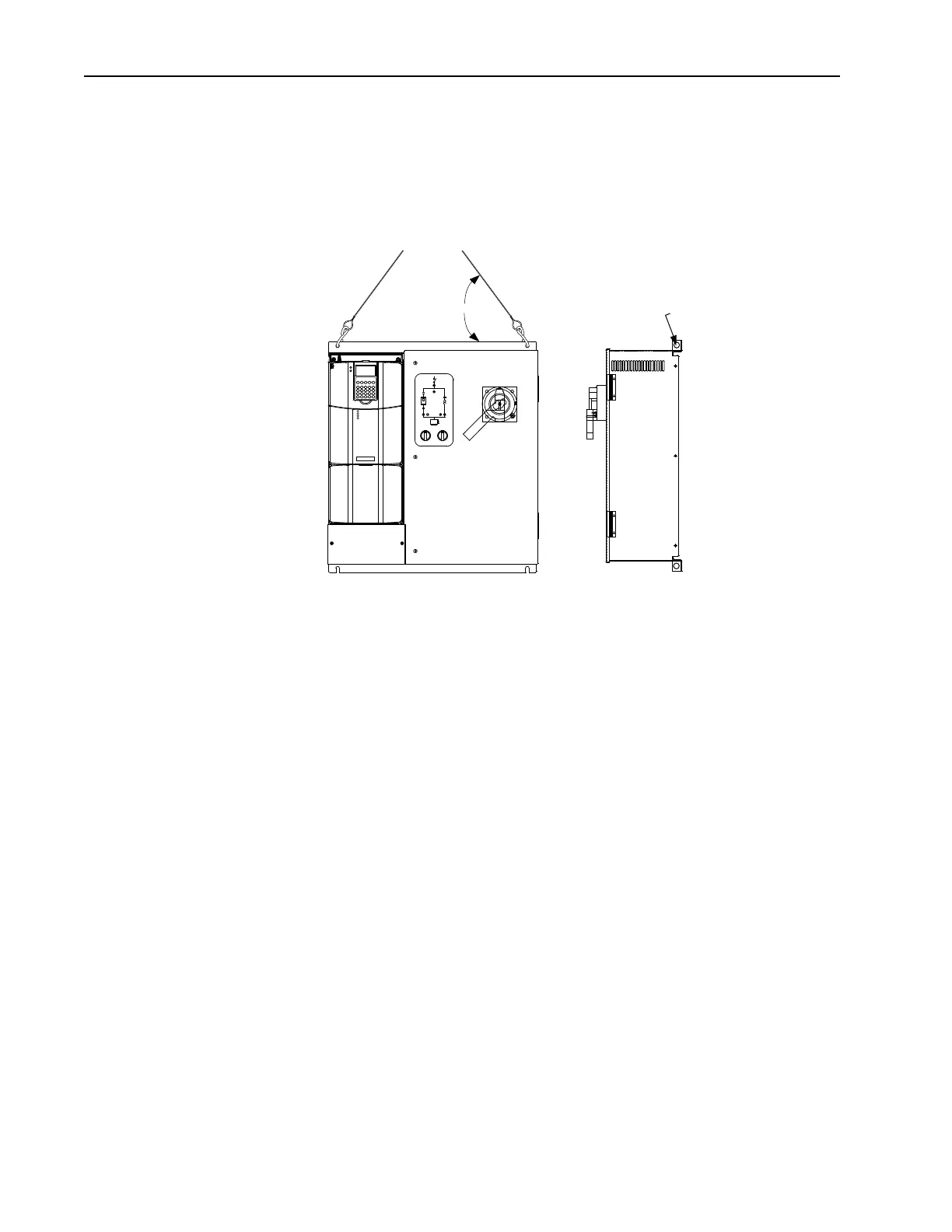

Lifting and Mounting the

Drive

Care should be used to prevent damage due to dropping or jolting when

moving the drive. A fork lift truck or similar means of lifting and

transporting may be used. Sling in a manner that will equalize the load at

the pickup points. Use a spreader bar if the angle of the sling is less than 45

degrees relative to horizontal. Do not jolt while lifting.

Figure 4.5 Lifting the Drive

Use the following procedure to lift and mount the drive.

1. Attach a sling with safety hooks or clevis clamps to the two lifting holes.

Make certain that the angle of the sling is not less than 45 degrees

relative to horizontal.

2. Using an overhead or portable hoist, attach a free-fall chain to the chain

secured to the drive. Take up any vertical slack in the chain.

3. Using the hoist, lift the drive from the horizontal shipping pallet.

4. Position the drive.

5. Attach the drive to a vertical surface using the mounting holes provided.

Use washers under the bolt heads.

DRIVE

OFF

HAND AUTO

MOTOR

TEST

BYPASS

DRIVE

MOTOR

BYPASS

RUN

SEE DRIVE DISPLAY

FOR DRIVE STATUS

READY

PURGE

DO C

DRIVE

DIC

OL

BYPASS

TRIP

BC

OUPUT

ENABE

DRIVE

Lifting Hole

45˚ Min.

Front View Right Side View

INTERLOCK

OPEN

Loading...

Loading...