hypercharger - Operation Instructions and Installation Guide

Hardware

Version 2-2

3 Packaging, transport and storage

All rights reserved. The reproduction of this document, also partially, is allowed only with authorization by alpitronic Srl

The following table allows for an easy weight calculation of the various hypercharger

configurations depending on the type of housing, number of stacks, number of DC-charging

interfaces and cooling units (max. 1 for HYC_150 and 2 for HYC_300).

Weight of

hypercharger [kg]

HYC_150

s… number of Power-Stacks

c… number of charging interfaces

cu…number of cooling units

~ 200+s*95+c*30+cu*12

<462

HYC_300

s… number of Power-Stacks

c… number of charging interfaces

cu…number of cooling units

~ 250+s*95+c*30+cu*12

<774

Table 17: Maximum weight and threat size for eyebolts for different hypercharger product types

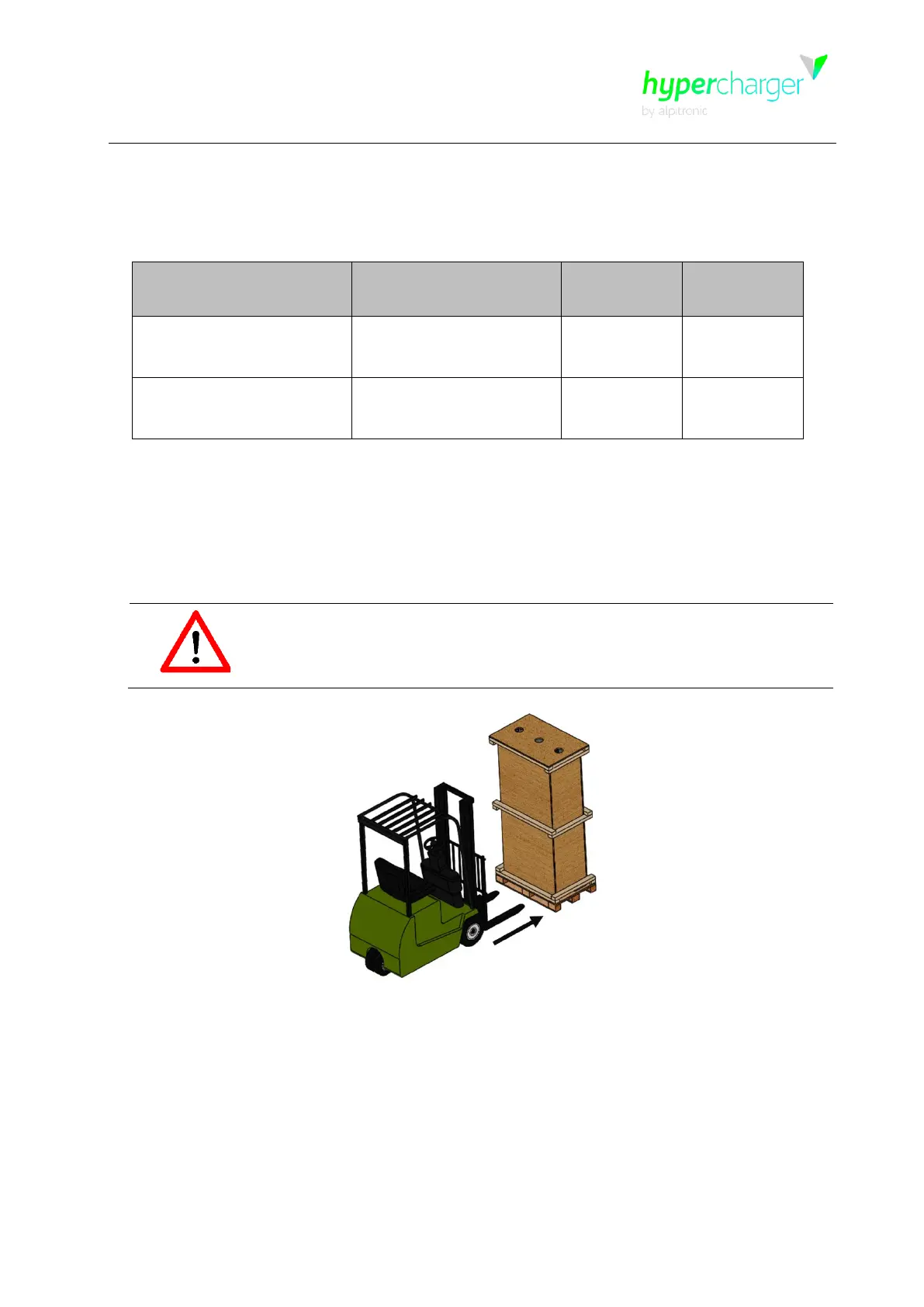

3.2. Transport and storage

Attention

In its wood packaging, the hypercharger must be transported vertically!

Figure 36: Vertical transport with pallet truck or forklift

In addition to the transport with a pallet truck or a forklift, the hypercharger can be moved by

crane, using the two (HYC_150 housing) or four (HYC_300 housing) crane eyelets. These

crane eyelets are mounted directly to the housing and are peeking through the packaging,

allowing the transfer of the charger while in its protective packaging.

Loading...

Loading...