hypercharger - Operation Instructions and Installation Guide

Hardware

Version 2-2

All rights reserved. The reproduction of this document, also partially, is allowed only with authorization by alpitronic Srl

8. Maintenance

Attention

Attention

Observe all hazard warnings in chapter 1.3

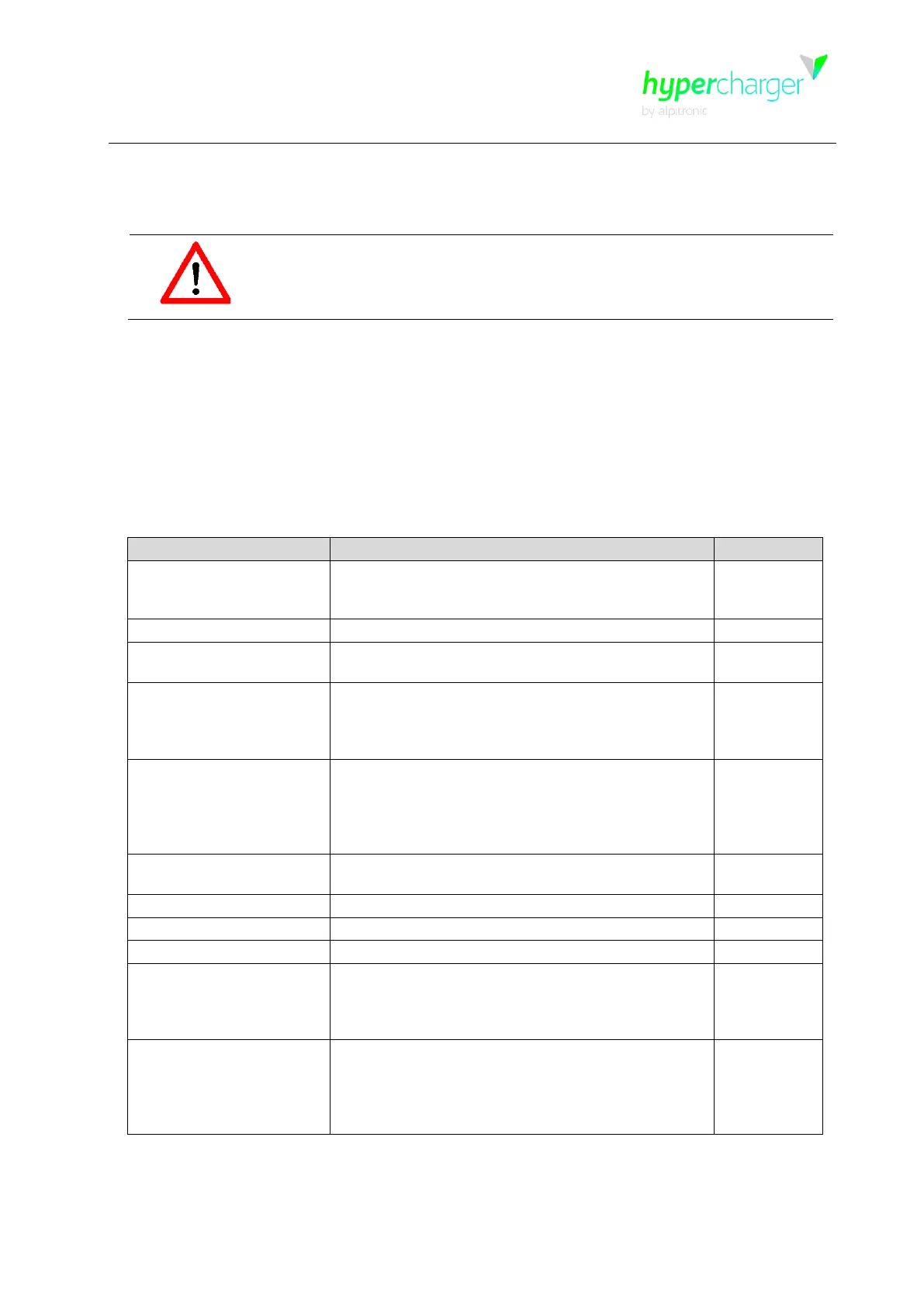

8.1. Overview of maintenance work

For the safe operation of the charging station, regular maintenance or control of the safety

equipment is required. All the points listed below are considered mandatory and must be

carried out by the operator at the intervals described.

Table 25 gives an overview of the required maintenance work. Depending on the individual

operating conditions of the hypercharger, further maintenance work may still be necessary

so the list below cannot be considered complete.

Replacement of the complete charging cable set

After 10000

charging

cycles

Function test of residual current circuit breaker

Main switch, voltage

release switch

Verify the correct function

Verification of protective

measures

With the charging station switched off, check the

resistance between the ground of the supply and all

externally accessible, non-insulated cabinet parts

(housing, add-on parts, screws)

Check for cleanliness and

condensation

Check if the interior of the control cabinet is clean

and without any traces of condensation.

Check the water run-off on cable plug holder and AC-

socket.

Check the seal for damage and correct positioning.

Random or complete testing of tightening torques at

terminals and mechanical screw connections.

Check the surge arrester for full function

Check the cooling liquid level (fill level indicator)

Concentration of cooling

liquid

Check the concentration (test with refractometer) of

the coolant liquid.

If the concentration is below 50 %, this can be

remedied by adding coolant concentrate.

Check the pH (optimal value - pH between 8 and 9)

of the coolant liquid.

If the pH is below pH 7.7, replace the coolant liquid.

Replacement of the majority of cooling liquid is

sufficient to ensure protection.

Table 25: Periodic maintenance work

Loading...

Loading...