Maintenance GT3000

IMGT30017EN 51

Converters stocked (non-operational) for two (2) years and longer: Use method 2A or method 2B (below) for capacitor reforming.

Reforming Method 2A

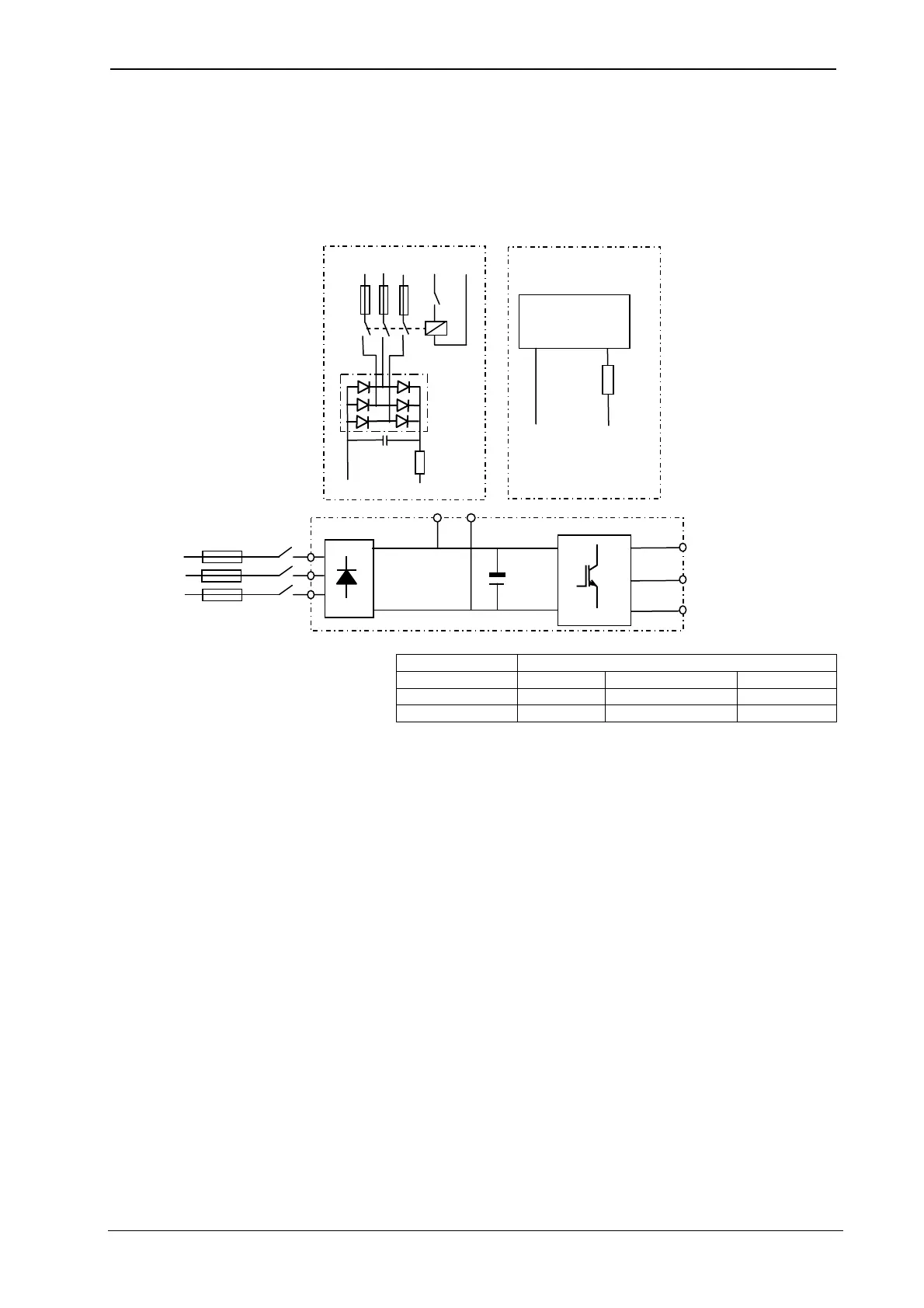

Capacitor reforming is achieved by switching in a rectifier and a resistor circuit, which are connected to the converter DC link. The

reforming circuit (Fig.2A.2.2) is shown below (B = Rectifier; R = Resistor; C = Capacitor).

Circuit component values for different voltages are given in the table 2A.2.1. Refer to the reforming time required from Fig. A.2.1.

WARNING! The converter supply must be disconnected, while reforming circuit is connected.

Figure 2A.2.2

Table 2A.2.1 Component values for reforming.

Components

Diodes R C

380V < Ux < 500V SKD100/16 470 Ohm / 1200W 22Nf /2000V

525V < Ux < 690V SKD100/16 470 Ohm / 1200W 22Nf /2000V

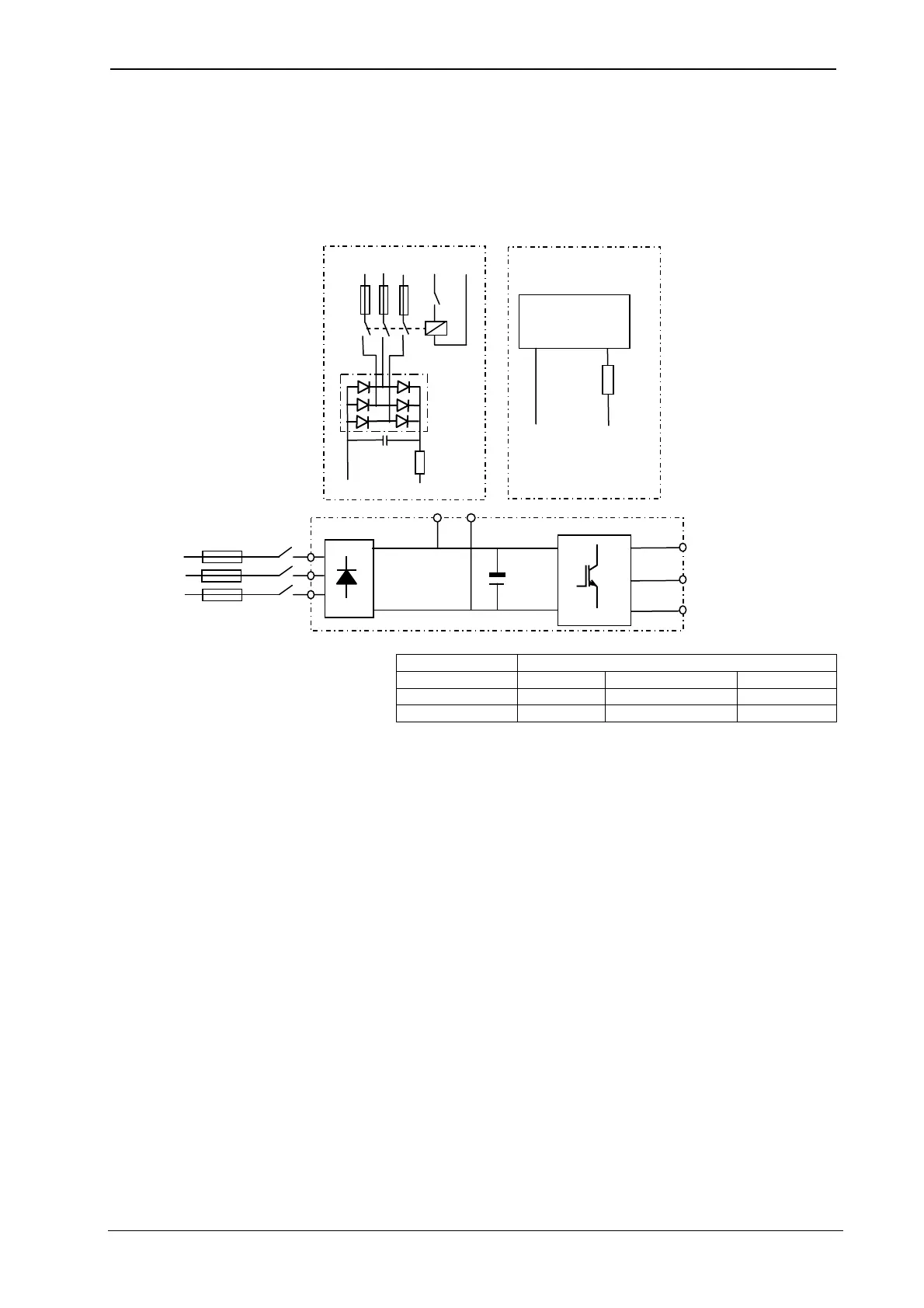

Reforming Method 2B

This capacitor reforming method is based on availability of a DC power supply, which is connected to a converter DC link. An appropriate

reforming voltage is (1.35... 1,8) x UX. Power supply current charges the converter capacitors. The power supply must be able to limit

current to 500mA or less. If the power supply doesn’t provide current limiting, then a resistor (R) should be installed as an option. Again,

refer to reforming time required from Figure 1.

WARNING! The converter supply must be disconnected, while the reforming circuit is connected.

Keeping Drives Ready for Production

Annual reforming of stored or non-used drives ensures that they remain at the ready, to provide the peak capacities and the operational

parameters that were manufactured into the converters originally.

Neglecting this critical maintenance procedure can, in a worst-case scenario, result in the capacitors failing, as well as the drives.

For more detailed help regarding the procedures above, call Answer Drives Customer Service.

4A.4 Disposal

The GT3000 drive does not come under some category of products included in the 2002/96/CE (RAEE) Directive, at which also the

2002/95/CE (RoHS) Directive refers, so it is not subjected to these Directive.

The GT3000 drive cannot be considered a "finished product" according to the 2002/96/CE Directive and the Directive does not cover

being it for industrial plants

The GT3000 drive cannot be used in other equipments/devices that must be compliance to the above European directives.

The Answer Drives products are designed and manufactured with particular attention to the environmental impact. Most part of the

components of the drives are recyclable or easily disposable according the RAEE Directive.

GT3000 contains raw materials that must be recycled to save energy and preserve the environment.

GT3000 does not contain toxic or harmful materials. Packaging materials and all metal parts can be recycled.

Parts of plastic materials can be recycled or burnt in a controlled manner according to local regulations.

The capacitors of the intermediate circuit (DC BUS) contain electrolyte, and the PCBs contain lead that must be removed and treated

according to local laws in force at the time of disposal.

-

Method 2A

Method 2B

DC

Power supply

R1

-

+

C

-

+

Loading...

Loading...