GT3000 Installation

42 IMGT30004EN

3A.6 ENCODER CONNECTION

3A.6.1 General data

"FOC" control needs an incremental encoder installed on the motor shaft (zero impulse is not necessary for standard applications).

It is possible to manage the encoder either line driver or push-pull electronic circuit. The GT3000 foresees two terminals for the feeding at 5V of

the encoder. For the connection of the encoder and the customization of the card see chapter 3A.2.4.5 and 3A.3 of the this Manual.

Encoders with whatever pulses/revolution can be used.

Maximum input frequency of the control card: FMAX = 100KHz.

The duration of the zero impulse must be included between electrical 90° and 360°.

Termination resistor for encoder line-driver: 120Ω

The maximum speed in rpm of the encoder (motor) can be calculated using the following formula:

3A.6.2 Connection modes

Mount the eventual external feeder as close as possible to the encoder following the instructions given in chapter 3A. 4.

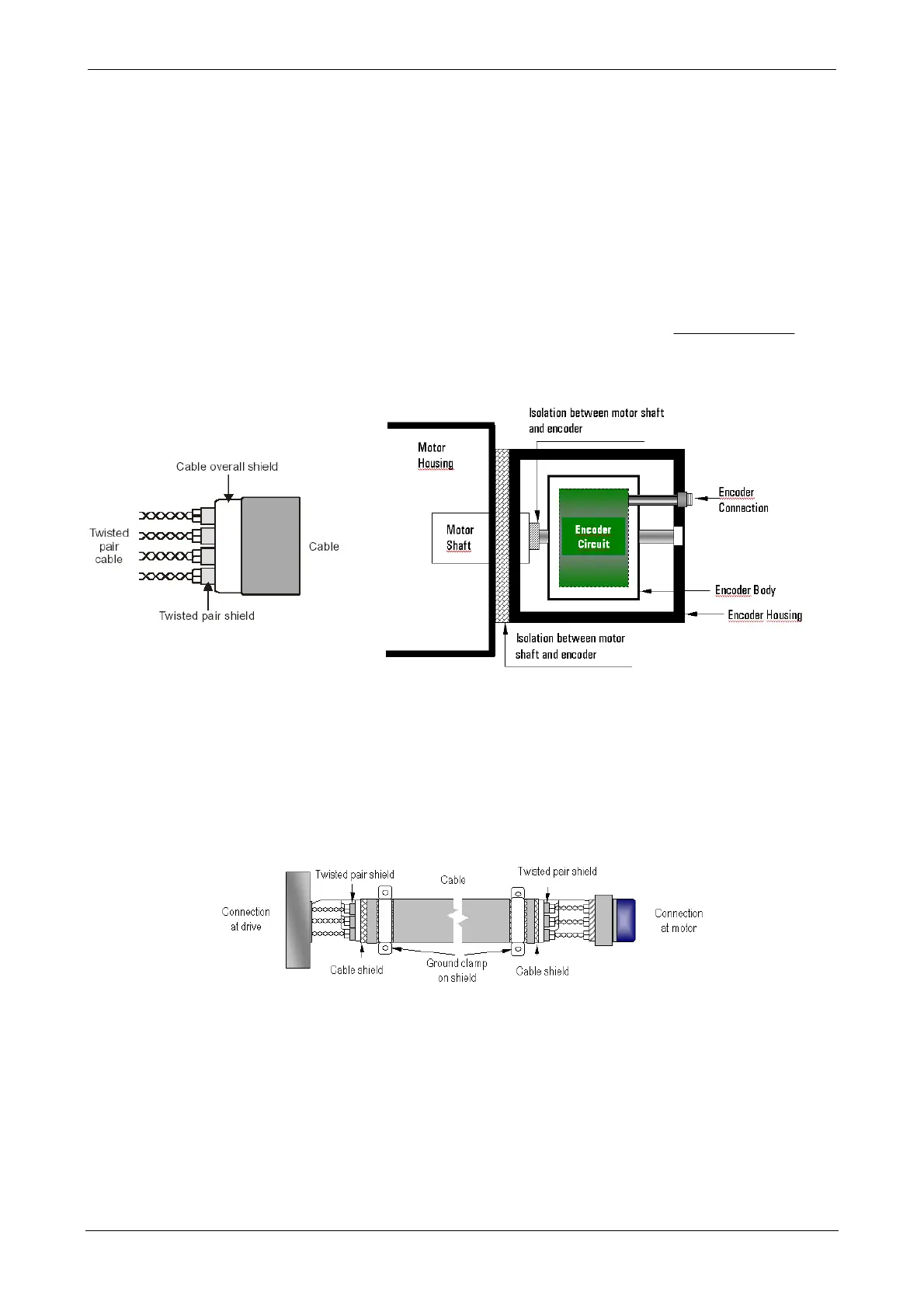

For the connection of the encoder, a cable with twisted

singularly shielded pairs shall be used.

Typical value:

single cable section: AWG24 ( 0,22mm

2

)

capacity between the cables : 50 pF/ m

capacity between cable and shied: 90 p/F m

SAP code: ELP20470101

It is compulsory:

to use an encoder with galvanic insulation between its structure and its

electronic circuits.

to use an encoder with protection against polarity inversion of power supply

and against short circuit at output.

to assembly the encoder on the motor so that to have galvanic insulation

between the motor housing/shaft and encoder.

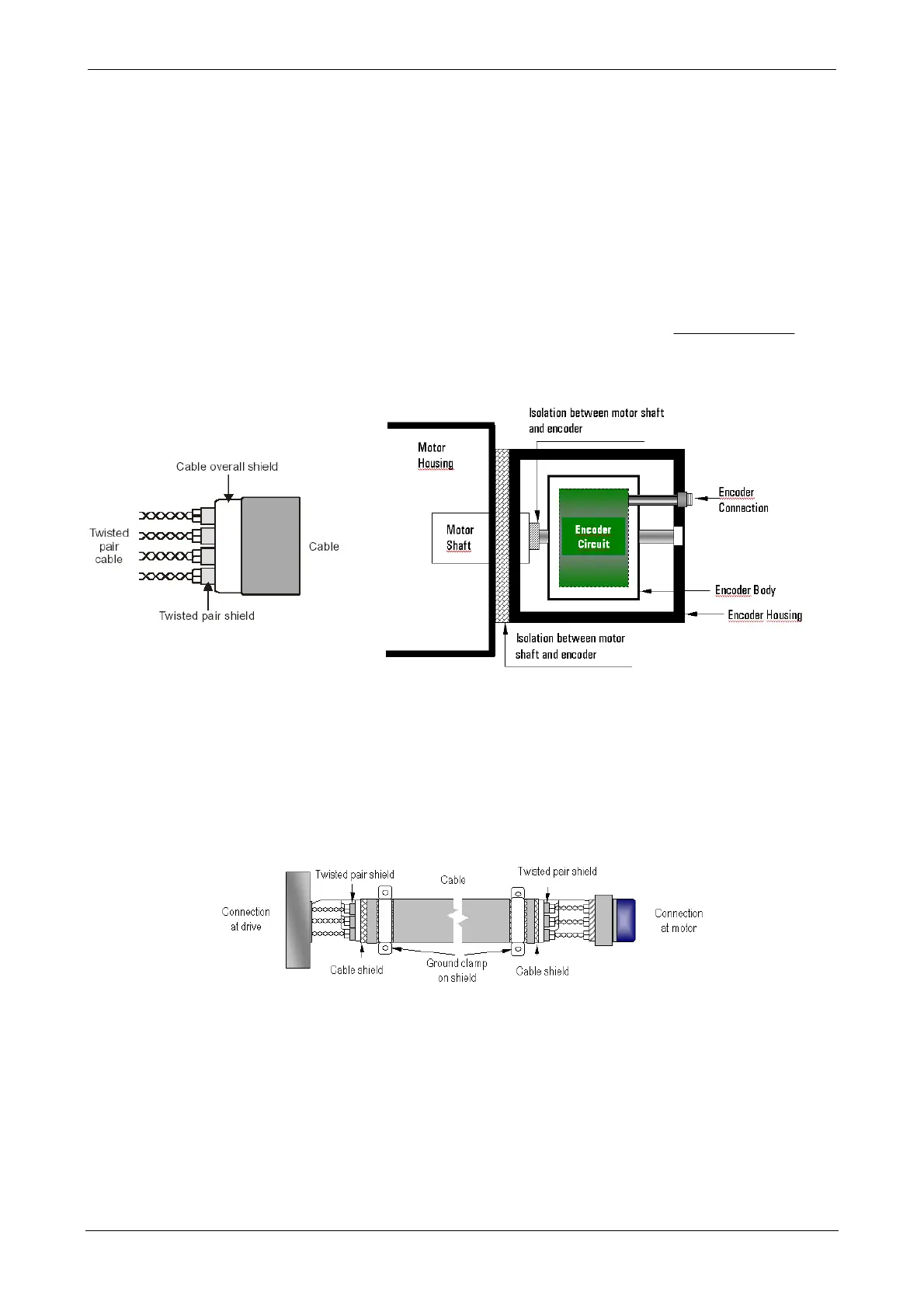

Connect the shields of the cable to the shield bar in the converter using connections of the shortest length as possible (“pigtails”).

The ground connection of the shield is optional. It can be required to reduce the emission of radio frequency noise emitted both from the drive and

from the encoder. The connection must be performed connecting directly the shield to metallic parts (for example to the body of the encoder

avoiding pigtails) and to the ground terminal of the converter.

The cable must not be interrupted. Should it not be possible to avoid interruptions, provide for the absolute minimum length of the “pigtail” in the

connections of the shield in correspondence of each interruption. Preferably use a connection method with sturdily-built metallic terminals for the

terminations of the cable shield.

This can be obtained by blocking the single shields, or by supplying an additional total shield to be blocked by means of the terminal.

The external sheath of the cable must be removed as necessary to allow the installation of the terminal. The shield must not be broken nor open in

this point. The terminals must be installed close to the converter or to the feedback device with ground connections performed on a proper plate or

on a similar metallic surface.

Note: 1 In the multidrive applications, if an external power supply is used, we suggest to use a power supply for every encoder.

2 If the encoder cables are longer than 60m we suggest to use encoder supplied at 24V.

3 The failure to ground connect the shield to both ends, due to noise voltage, can cause the breakage of the line driver of the

encoder and/or of the drive receiver.

olutionpulses/revN

60*F

Rev

MAX

MAX

Loading...

Loading...