DrillSaw Highspeed 200™ User’s Guide

DFU-0225-2 Rev. 0 Page 42 of 58

Automatic wash cleaning solutions may include, but are not limited to:

neodisher® Mediclean forte, Thermosept® alka clean, Prolystica® Ultra

Concentrate Enzymatic Cleaner, and ProKlenz NpH Neutral Detegent.

CAUTION: Low acid or high alkaline solutions are not recommended, as they

corrode metal parts and anodized aluminum and compromise polymer

plastics, such as FEP (Fluorinatedethylenepropylene), ABS (Acrylonitrile

Butadiene Styrene), Ultem™, Lexan™, and Cycolac™. If non-neutral pH

cleaning chemistries are utilized, care should be taken to ensure appropriate

rinsing and neutralization steps are taken so as to not negatively impact the fit,

finish, or function of the device.

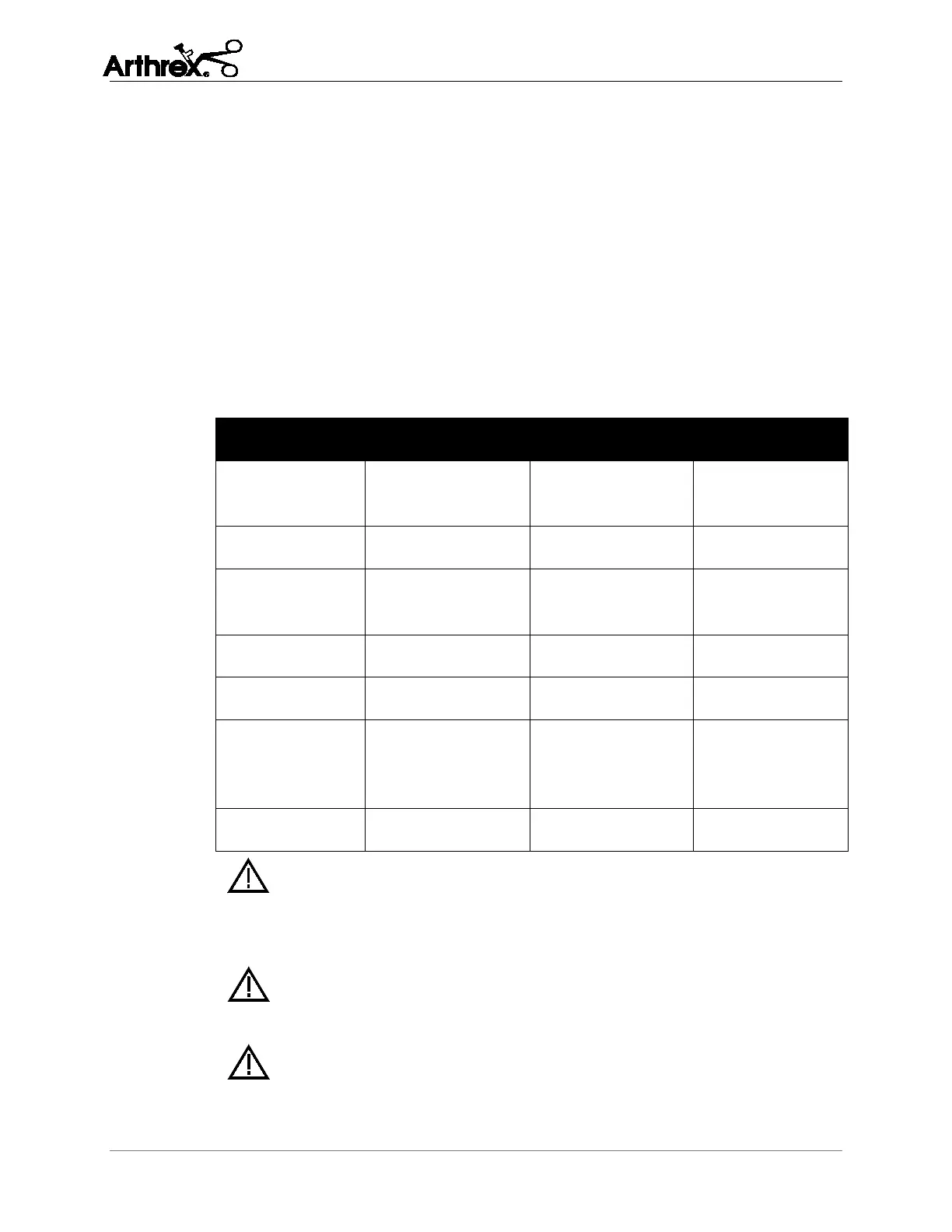

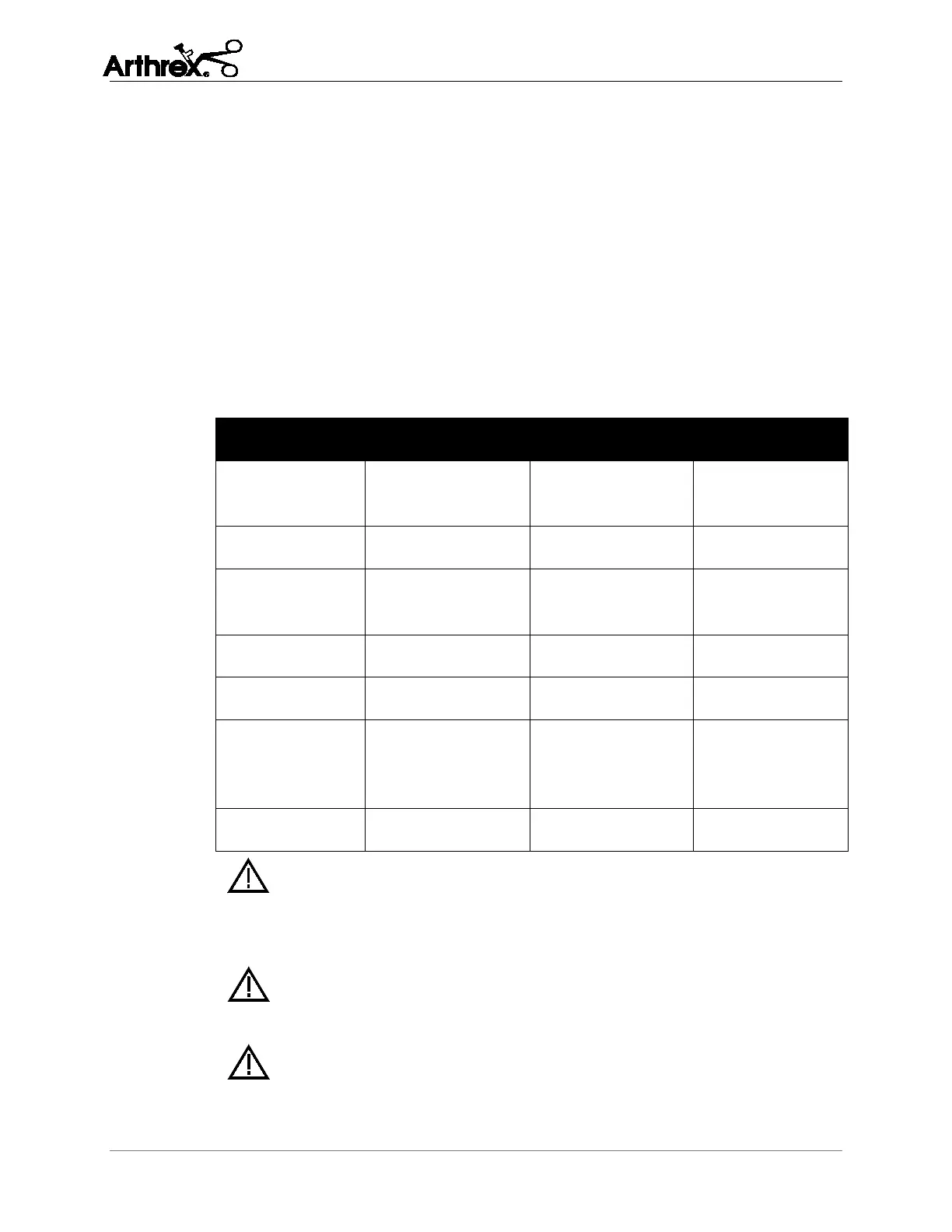

Machine Wash Parameters:

MINIMUM WASHING CYCLE PARAMETERS

Phase

Recirculation

Time

Temperature Detergent

Cold Pre-Wash 3 Minutes 68 ± 9°F (20 ± 5°C) N/A

Cleaning Wash 10 Minutes

150 ± 9°F

(65.5 ± 5°C)

Enzymatic or

alkaline agent

Rinse 1 3 Minutes 122 ± 9°F (50 ± 5°C) N/A

Rinse 2 3 Minutes 122 ± 9°F (50 ± 5°C) N/A

Thermal

Disinfection

Rinse

5 Minutes 194 ± 9°F (90 ± 5°C) N/A

Drying 6 Minutes 239°F (115°C) N/A

NEVER allow the motor with cable receptacles to have any contact

with liquids. If there is dust or moisture on the receptacles, remove

using dry compressed air. ONLY dry connectors should be

plugged into the console.

Before starting operation again: Wait until the motor and cable are

completely dry. Moisture in the plug or motor can lead to a

malfunction. (short circuit)

Do NOT clean the device with abrasive cleaning or disinfectant

compounds, solvents, or other materials that could scratch or

damage the device.

Loading...

Loading...