Do you have a question about the Assa Abloy ACCENTRA 6000 Series and is the answer not in the manual?

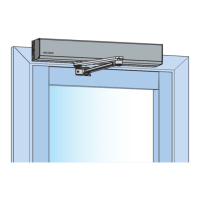

The 6000 Series Motorized Electric Latch Retraction (MELR) Exit Device is a commercial-grade solution designed to provide remote-controlled latch retraction for various 6000 series exit devices (including 6100, 6130, 6150, 6160, 6170, 6200, 6210, 6250, and 6220). This system offers enhanced security and convenience through its electrical control capabilities and compatibility with several monitoring options. The MELR option is also compatible with hex key, cylinder key, and fire-rated mechanical configurations, offering flexibility in application.

The MELR option can be configured to operate in two distinct modes:

The MELR system integrates with several optional monitoring switches to provide comprehensive status feedback:

| Brand | Assa Abloy |

|---|---|

| Model | ACCENTRA 6000 Series |

| Category | Door Opening System |

| Language | English |

Loading...

Loading...