27 Rev. 00

5.5 How to work a profil

The machine can work profiles with various sizes and features. Therefore, the user must carry out

the machine set up in order to adjust the various tools according to the profile to be machined.

The machine adjustings are the following:

— adjusting vertical cylinder;

— adjusting the eccentric guides;

— mounting and adjusting the bracing clamp;

— mounting and adjusting the crimping knives;

— adjusting the reference forks.

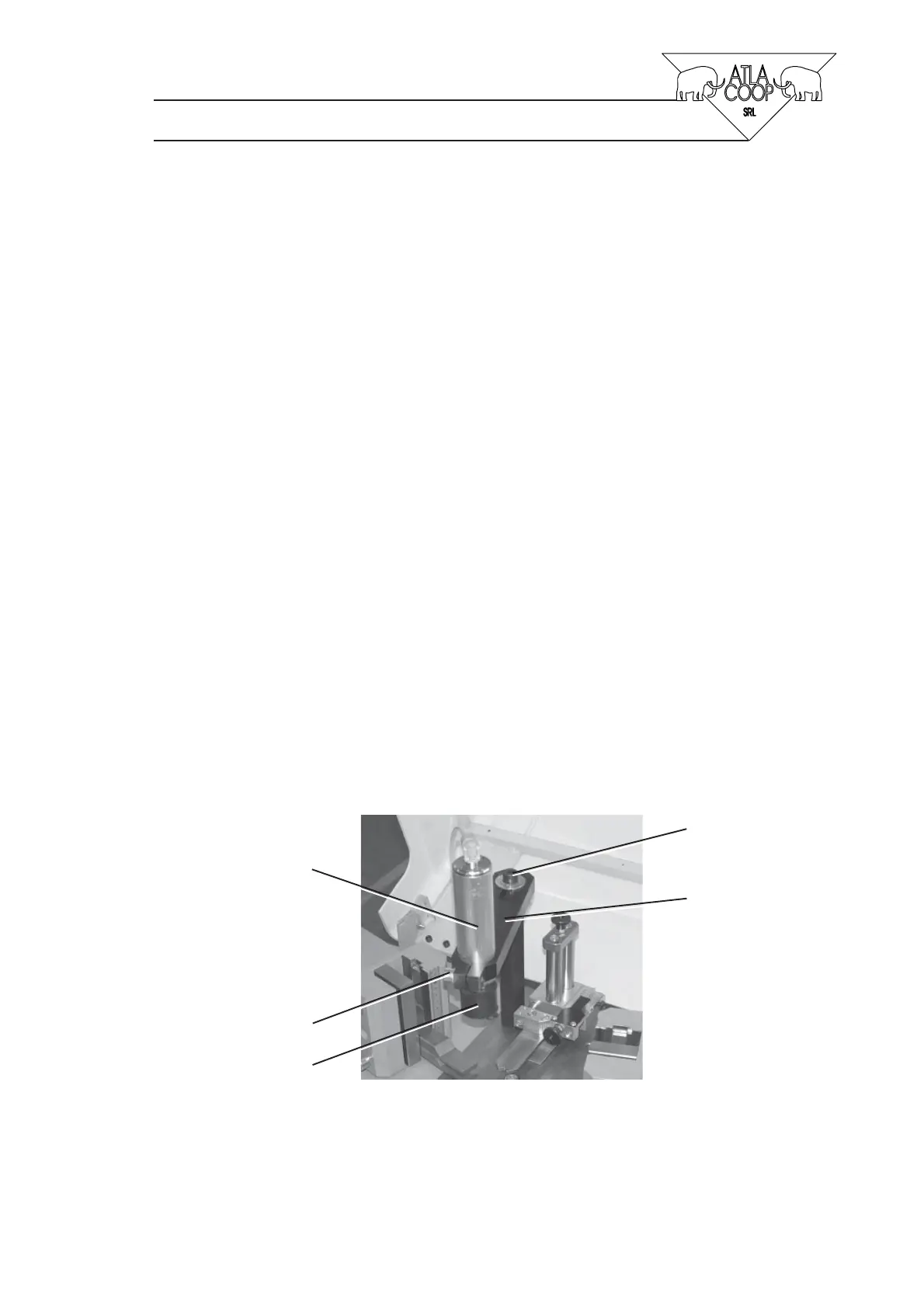

5.5.1 HOW TO ADJUST THE VERTICAL CYLINDER

— Open the safety guard.

— Position a sample profile on the worktable.

— Loose the screw (1, fig. 5.3).

— Swing the profile clamp holder (2) until the cylinder (3) is aligned with the profile.

— Tighten the screw .

— Loose the screw (4).

— Move downward the cylinder (5) until its plunger is at a distance of 5÷10 mm from the profile.

— Tighten the screw (4).

Fig. 5.3

3

5

1

2

4

Loading...

Loading...