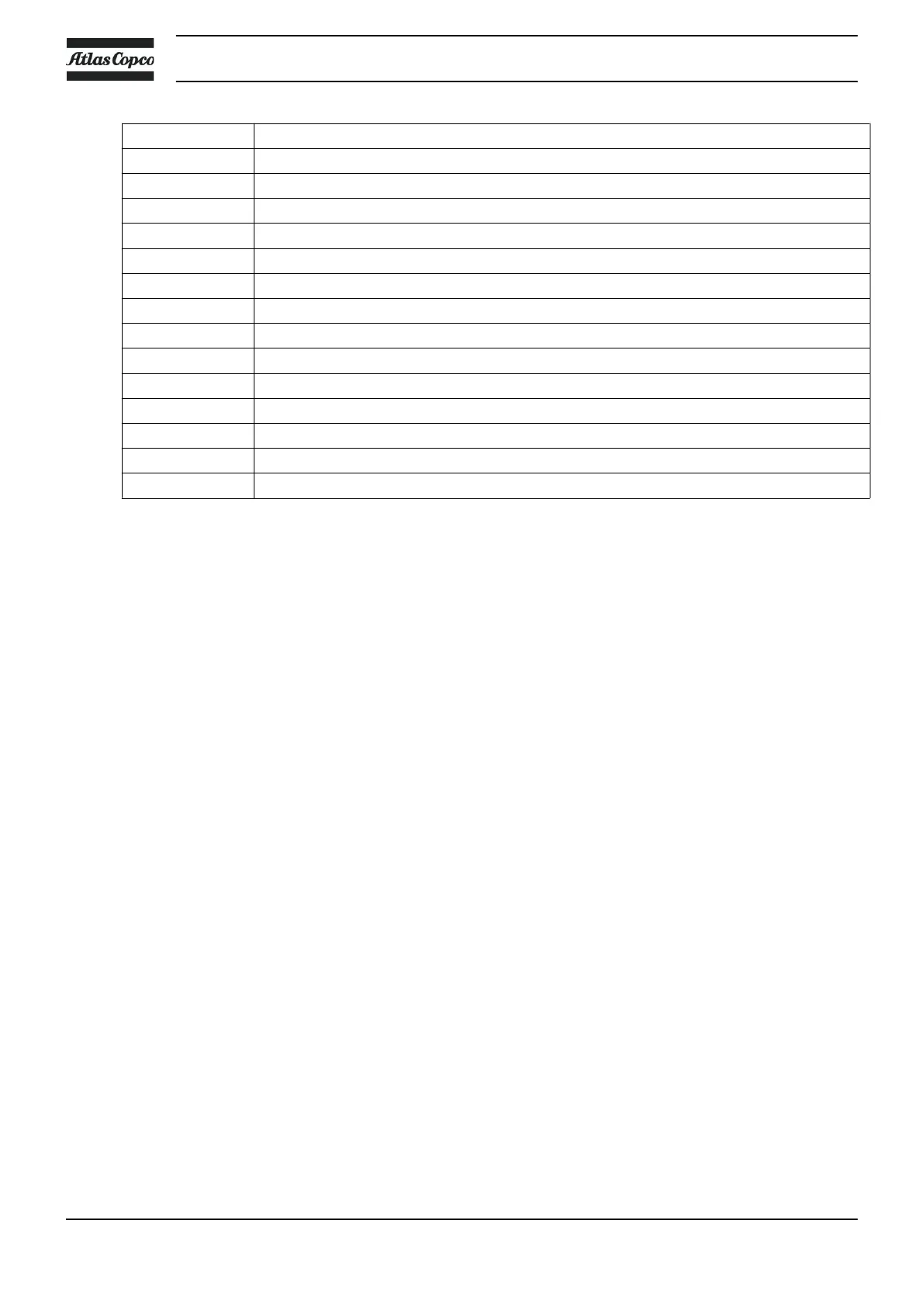

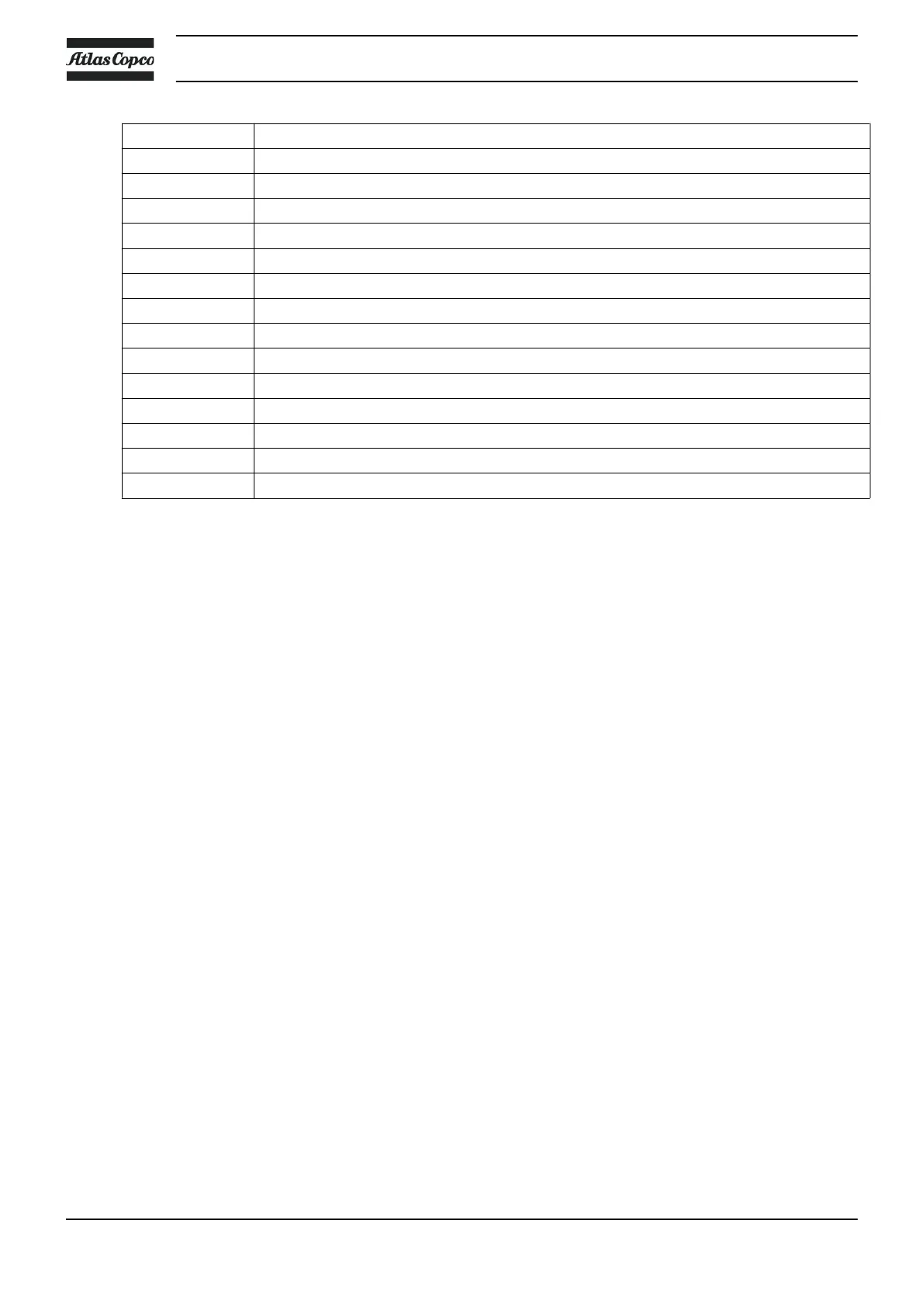

Reference Designation

1 Water inlet pipe

2 Water outlet pipe

3 Temperature sensor, water inlet pipe

4 Temperature sensor, water outlet pipe

5 Oil drain plug

6 Oil flexible from compressor oil separator vessel to ER unit

7 Oil flexible from ER unit to oil filter housing

PRV Pressure relief valve

BV2 Location of heat exchanger by-pass valve (BV2)

HE Heat exchanger

V1 Selector valve

AR Oil separator tank

OF Oil filter housing

BV1 Location of oil cooler bypass valve (BV1)

Field installation

The main components are assembled ex-factory as a compact unit which fits inside the bodywork of the

compressor. Consult your dealer for installing and connecting the energy recovery unit.

5.2 Energy recovery systems

General

The energy recovery systems can be applied as low temperature rise/high water flow systems or as high

temperature rise/low water flow systems.

Low temperature rise/high water flow systems

For this type of application, the temperature difference between the water in the energy recovery system

and the compressor oil is low. As a consequence, a high water flow is needed for maximum energy

recovery.

Example: The heated water is used to keep another medium at a moderately high temperature, in a closed

circuit, e.g. central heating.

High temperature rise/low water flow systems

For this type of application, a high water temperature rise in the energy recovery system is obtained, which

consequently brings on a low flow rate.

Example: An open circuit where cold water from a main supply is heated by the energy recovery system

for use in a factory, e.g. pre-heating of boiler feed water.

Recovery water flow

For the references, see section Energy recovery data.

Instruction book

120 2920 7180 30

Loading...

Loading...