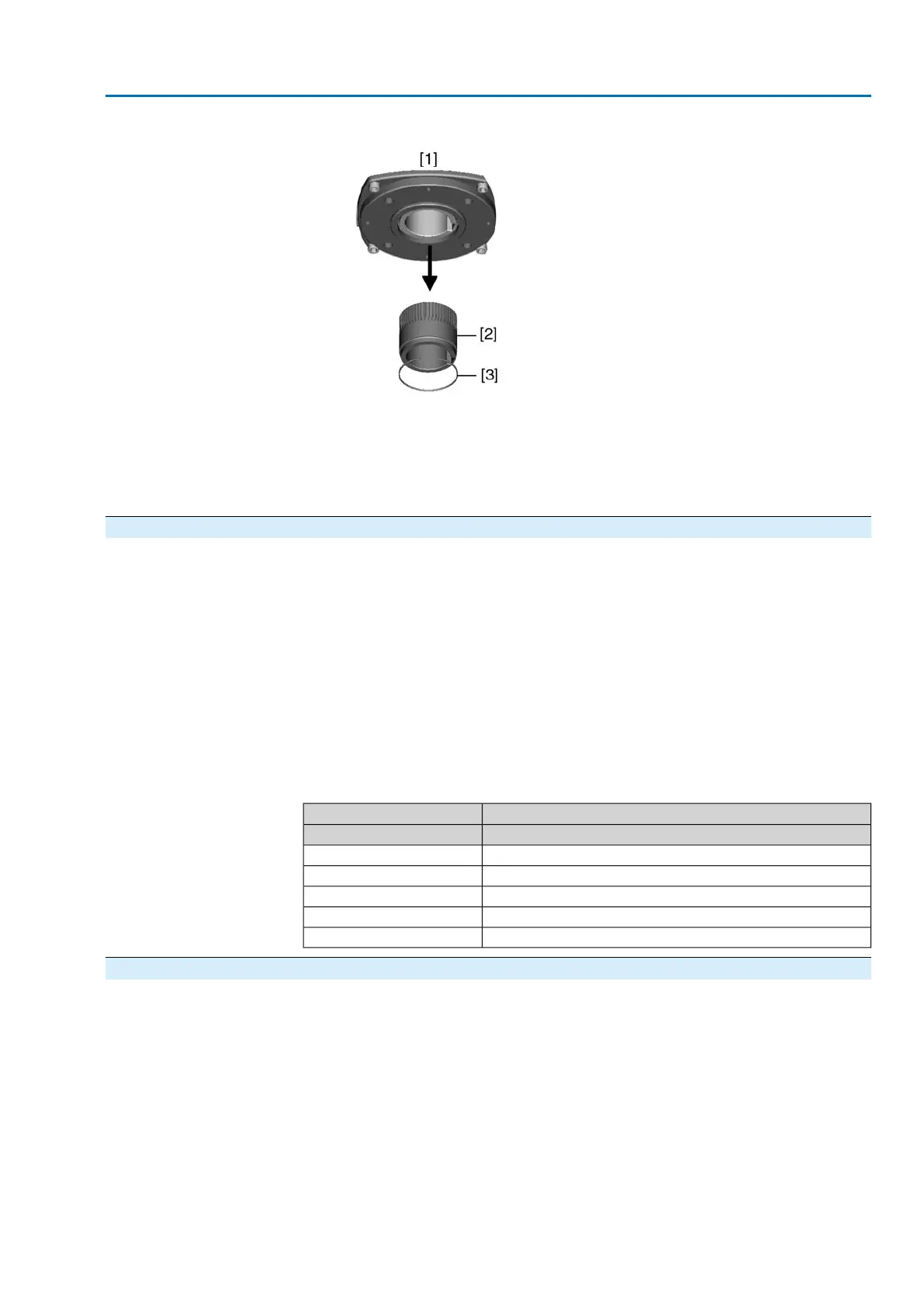

Figure 6: Output drive

[1] Output drive types B, B1 – B4, E and C

[2] Output drive sleeve/output drive plug sleve with bore and keyway

[3] Circlip

Information Spigot at flanges should be loose fit.

4.3.1.1 Multi-turn actuator (with output drive types B1 – B4 or E): mount to valve/gearbox

1. Check if mounting flanges fit together.

2. Check whether bore and keyway match the input shaft.

3. Apply a small quantity of grease to the input shaft.

4. Place multi-turn actuator.

Information: Ensure that the spigot fits uniformly in the recess and that the

mounting faces are in complete contact.

5. Fasten multi-turn actuator with screws according to table.

Information: We recommend applying liquid thread sealing material to the

screws to avoid contact corrosion.

6. Fasten screws crosswise to a torque according to table.

Table 2: Tightening torques for screws

Tightening torque T

A

[Nm]Screws

Strength class 8.8Threads

25M8

51M10

87M12

214M16

431M20

4.3.2 Output drive type A

Application

●

Output drive for rising, non-rotating valve stem

●

Capable of withstanding thrust

Information To adapt the actuators to output drive types A available on site with flanges F10 and

F14 (year of manufacture: 2009 and earlier), an adapter is required. The adapter

can be ordered from AUMA.

13

SA 07.2 – SA 16.2/SAR 07.2 – SAR 16.2 Control unit: electromechanic

AC 01.2 Intrusive Assembly

Loading...

Loading...