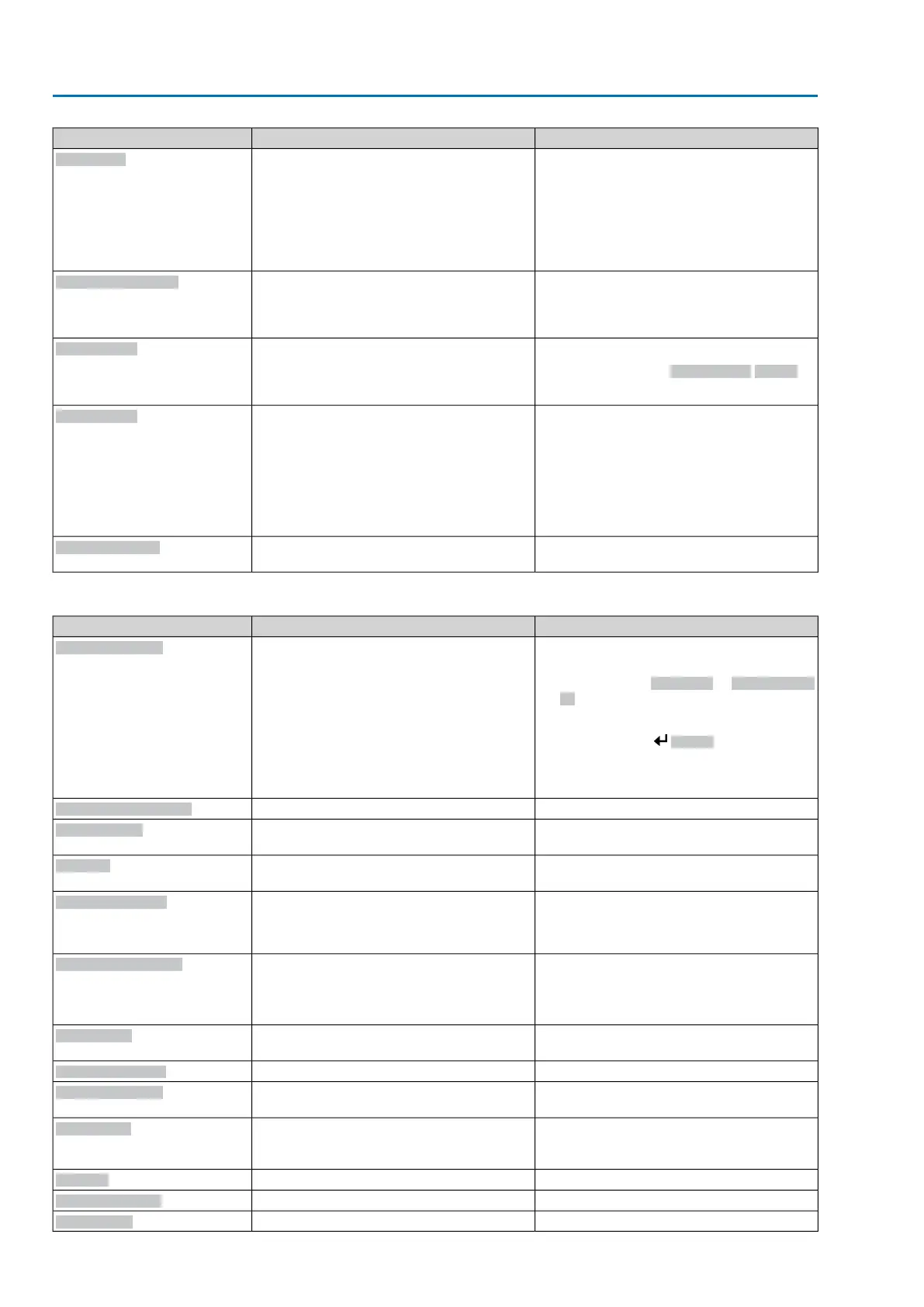

RemedyDescription/causeIndication on display

Test/connect phases.

●

When connecting to a 3-ph AC system and

with internal 24 V DC supply of the electro-

nics: Phase 2 is missing.

●

When connecting to a 3-ph or 1-ph AC

system and with external 24 V DC supply

of the electronics: One of the phases L1,

L2 or L3 is missing.

Phase fault

Correct the sequence of the phase conductors

L1, L2 and L3 by exchanging two phases.

The phase conductors L1, L2 and L3 are

connected in the wrong sequence.

Only applicable if connected to a 3-ph AC

system.

Incorrect phase seq

●

Check mains voltage.

●

Check parameter Tripping time M0172,

extend time frame if required.

Due to insufficient mains quality, the controls

cannot detect the phase sequence (sequence

of phase conductors L1, L2 and L3) within the

pre-set time frame provided for monitoring.

Mains quality

●

Cool down, wait.

●

If the fault indication display persists after

cooling down:

-

Set selector switch to position Local

control (LOCAL) and reset fault indica-

tion via push button RESET.

●

Check fuses.

Motor protection tripped

Thermal fault

Check movement at actuator.No actuator reaction to operation commands

within the set reaction time.

Fault no reaction

Table 14: Not ready REMOTE and Function check (collective signal 04)

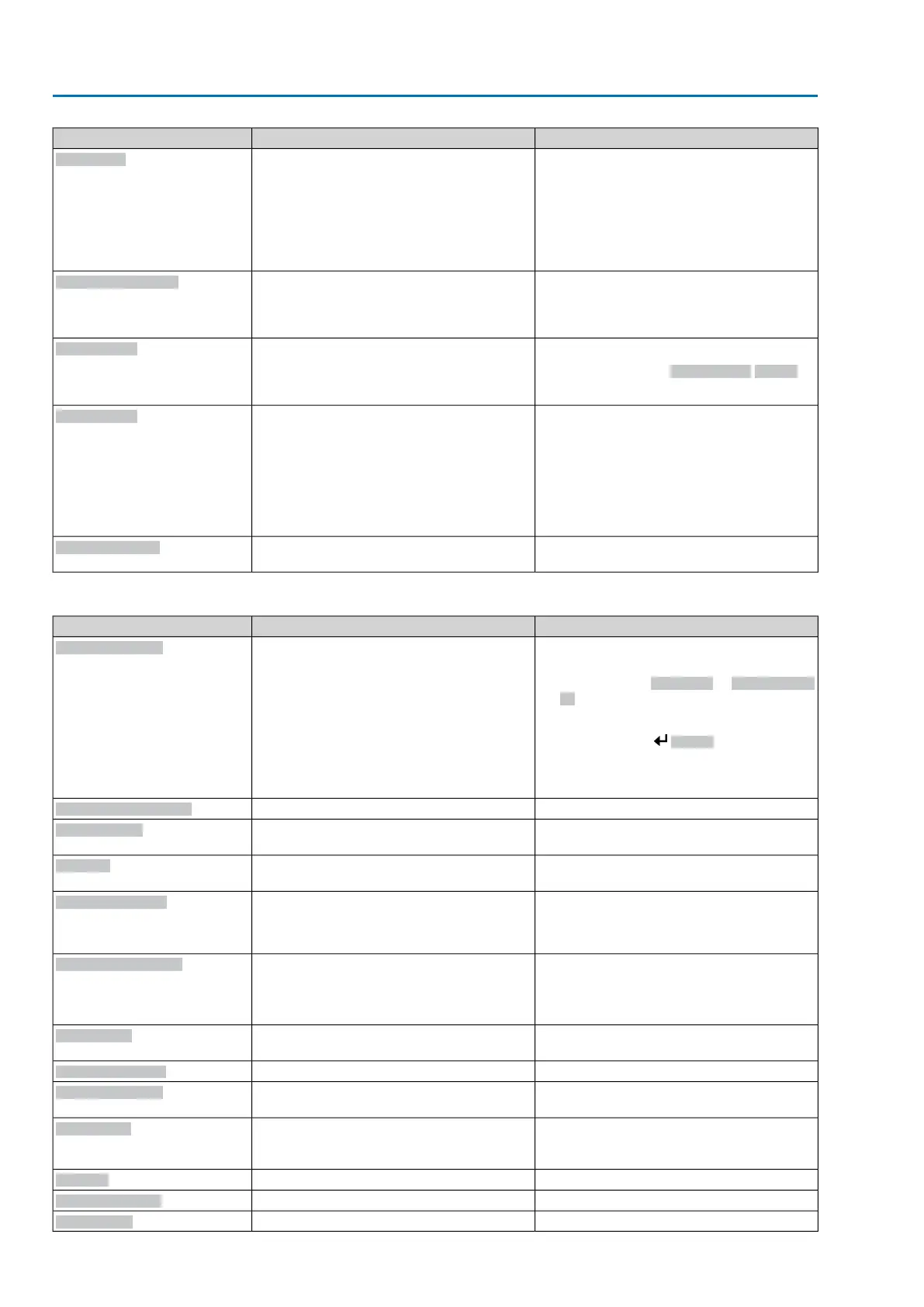

RemedyDescription/causeIndication on display

●

Check operation commands (send one

operation command only).

●

Set parameter Positioner to Function acti-

ve.

●

Check setpoint.

Press push button Details to display a list

of individual indications.

For a description of the individual signals, refer

to Manual (Operation and setting).

Collective signal 13:

Possible causes:

●

Several operation commands (e.g. OPEN

and CLOSE simultaneously, or OPEN and

SETPOINT operation simultaneously)

●

A setpoint is present and the positioner is

not active

●

For fieldbus: Setpoint exceeds 100.0 %

Wrong oper. cmd

Set selector switch to position REMOTE.Selector switch is not in position REMOTE.

Sel. sw. not REMOTE

Exit service software.Operation via service interface (Bluetooth) and

service software AUMA ToolSuite.

Service active

Check setting and status of function <Local

controls enable>.

Actuator is in operation mode Disabled.

Disabled

●

Enable EMERGENCY stop switch.

●

Reset EMERGENCY stop state by means

of Reset command.

The EMERGENCY stop switch has been

operated.The motor control power supply

(contactors or thyristors) is disconnected.

EMCY stop active

●

Detect cause for EMERGENCY signal.

●

Verify failure source.

●

Apply +24 V DC at EMERGENCY input.

Operation mode EMERGENCY is active

(EMERGENCY signal was sent).

0 V are applied at the EMERGENCY input.

EMCY behav. active

Check I/O interface.The actuator is controlled via the I/O interface

(parallel).

I/O interface

Start motor operation.Manual operation is activated.

Handwheel active

Verify master configurationFieldbus connection available, however no

process data transmission by the master.

FailState fieldbus

Release push button STOP.A local STOP is active.

Push button STOP of local controls is opera-

ted.

Local STOP

Check interlock signal.An interlock is active.

Interlock

Check states of main and by-pass valve.By-pass function is interlocked.

Interlock by-pass

Wait until PVST function is complete.Partial Valve Stroke Test (PVST) is active.

PVST active

54

SA 07.2 – SA 16.2/SAR 07.2 – SAR 16.2 Control unit: electromechanic

Corrective action AC 01.2 Intrusive

Loading...

Loading...