6.4. Accessories for electrical connection

6.4.1. Actuator controls on wall bracket

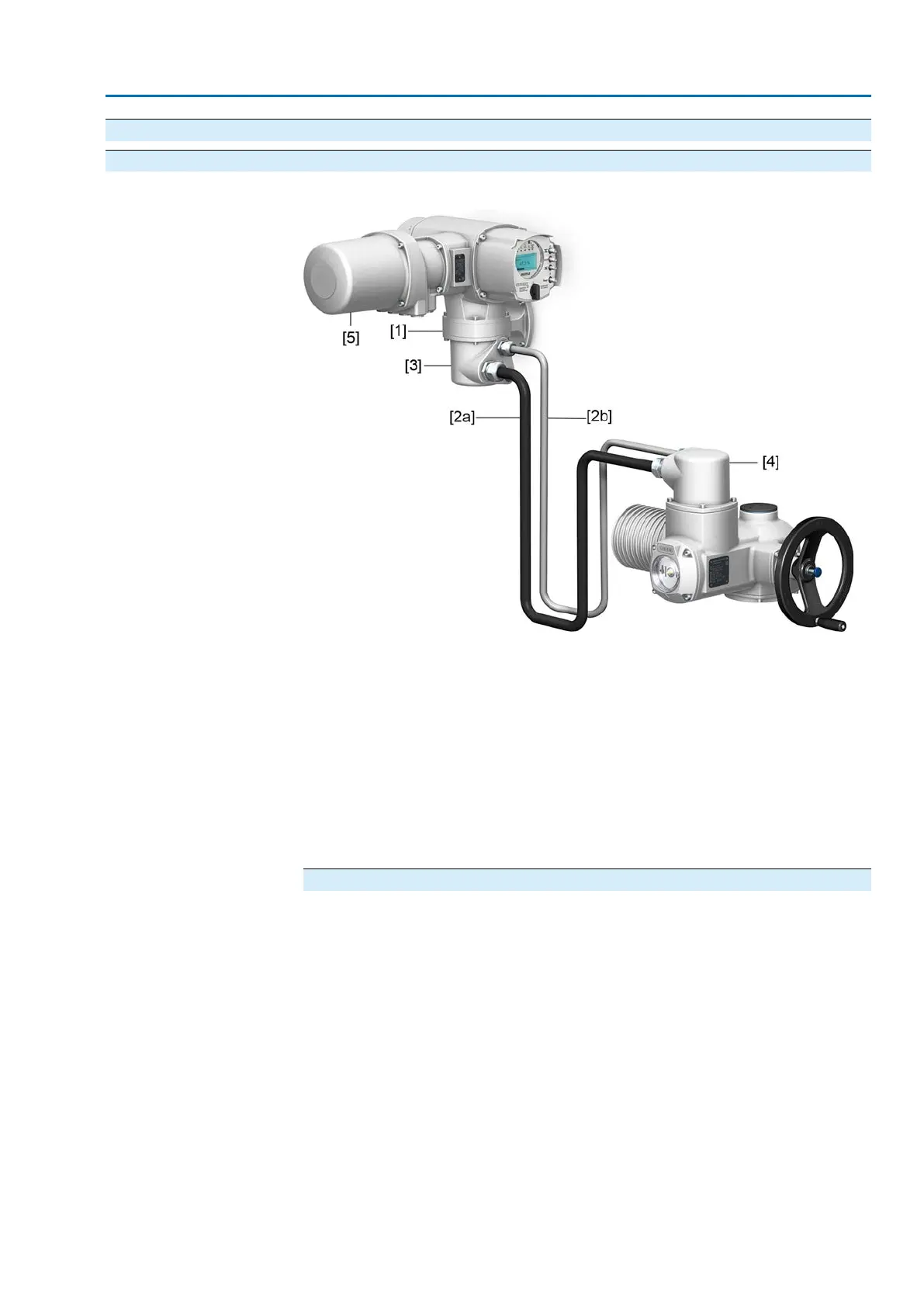

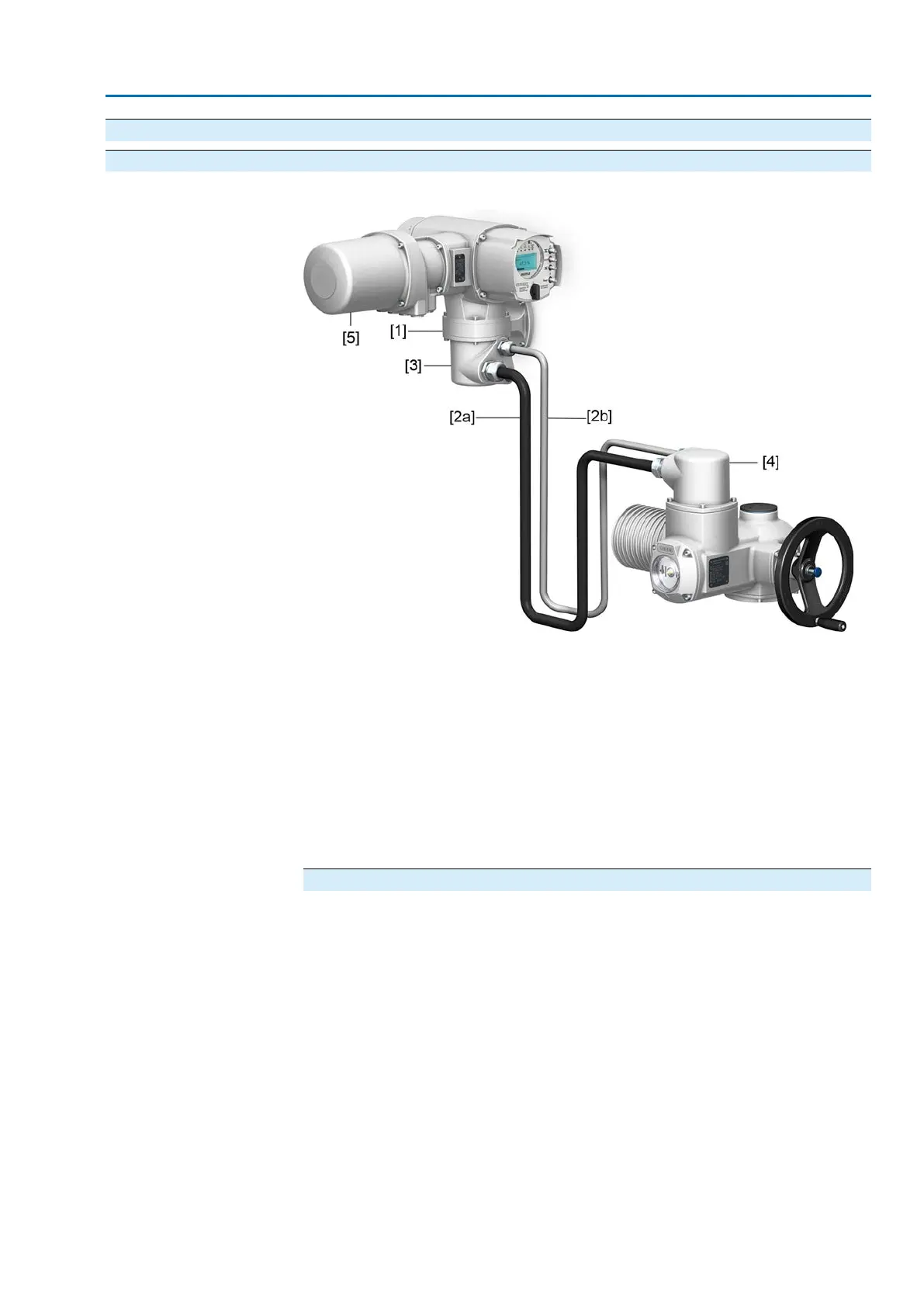

Design Figure 32: Design principle with wall bracket (example)

[1] Wall bracket

[2a] Motor connection/motor control

[2b] Feedback signals from actuator

[3] Electrical connection of wall bracket (XM)

[4] Electrical connection of actuator (XA)

[5] Electrical connection of actuator controls (XK)

Application

The wall bracket allows separate mounting of actuator controls and actuator.

●

If the actuator cannot be accessed safely.

●

If the actuator is subjected to high temperatures.

●

In case of heavy vibration of the valve.

Information on installation with wall bracket

●

The permissible cable length between actuator controls on wall bracket and

the actuator amounts to 100 m maximum.

●

We recommend using an AUMA “LSW” cable set.

●

If the AUMA cable set is not used:

- Use suitable flexible and screened connecting cables.

- Use separate CAN bus cable of 120 Ohm character impedance for MWG

(e.g. UNITRONIC BUS-FD P CAN UL/CSA - 2 x 2 x 0.5 mm², manufacturer:

Lapp).

- Data cable connection: XM2-XA2 = CAN L, XM3-XA3 = CAN H.

- Voltage supply MWG: XM6-XA6 = GND, XM7-XA7 = + 24 V DC (refer to

wiring diagram).

35

SA 07.2 – SA 16.2 / SAR 07.2 – SAR 16.2 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive DeviceNet Electrical connection

Loading...

Loading...