Commissioning (basic settings)

26

10

Commissioning (basic settings)

10.1

End stops in part-turn actuator

The internal end stops limit the swing angle. They protect the valve in case of limit

switching failure during motor operation and serve the purpose as limitation for manual

operation via handwheel. They may not be used for torque tripping in end positions

during standard operation.

End stop setting is generally performed by the valve manufacturer prior to installing

the valve into the pipework.

CAUTION

Exposed, rotating parts (discs/balls) at the valve!

Pinching and damage by valve or actuator.

à End stops should be set by suitably qualified personnel only.

à Never completely remove the setting screws [2] and [4] to avoid grease leakage.

à Observe dimension T

min.

The swing angle set in the factory is indicated on the name tag:

Figure21: Example of swing angle on name tag

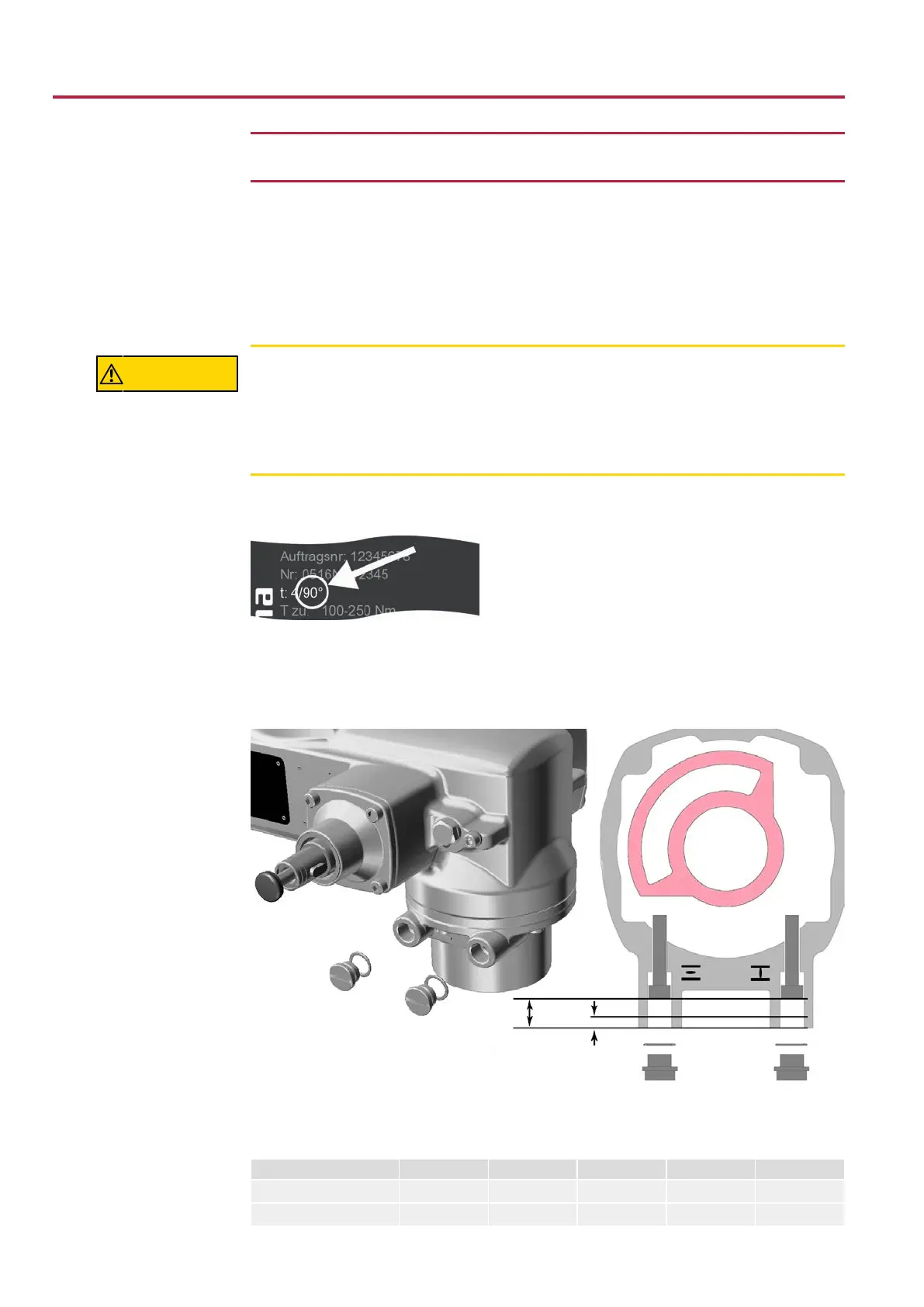

The setting sequence depends on the valve:

• Recommendation for butterfly valves: Set end stop CLOSED first.

• Recommendation for ball valves: Set end stop OPEN first.

Figure22: End stop

T T min.

[1]

[2]

[3]

[4]

[1]

[3]

[1] Screw plug for end stop OPEN [2] Setting screw for end stop OPEN

[3] Screw plug for end stop CLOSED [4] Setting screw for end stop CLOSED

Table15: Dimensions/size (mm)

Dimensions/size (mm) 05.2 75.0 [07.2] 75.0 [10.2] 75.0 [12.2] 75.0 [14.2]

T (for 90°) 17 17 20 23 23

T

min.

11 11 12 13 12

Loading...

Loading...