Servicing and maintenance

41

13.2.1

Disconnection from the mains with KES-d electrical connection

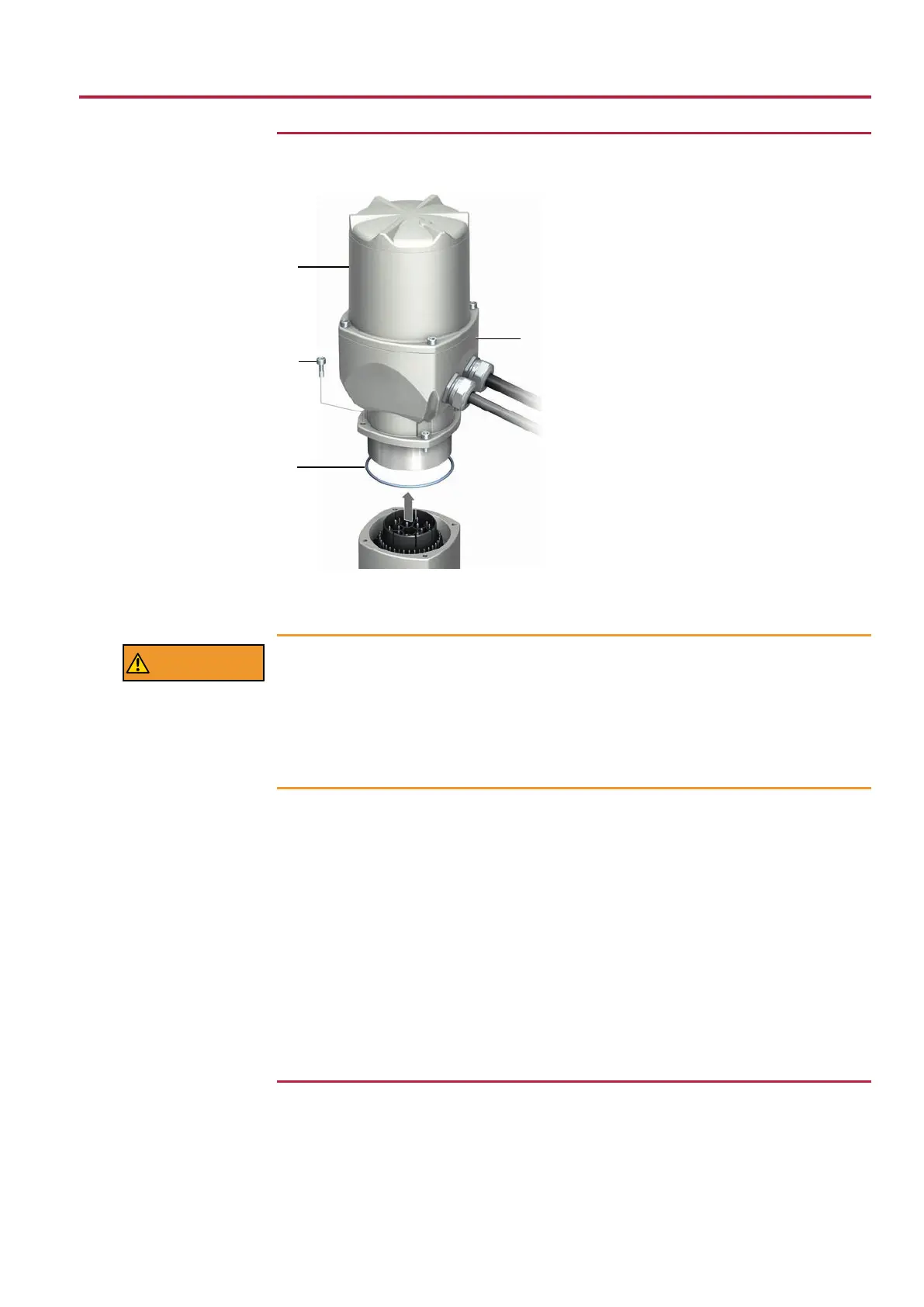

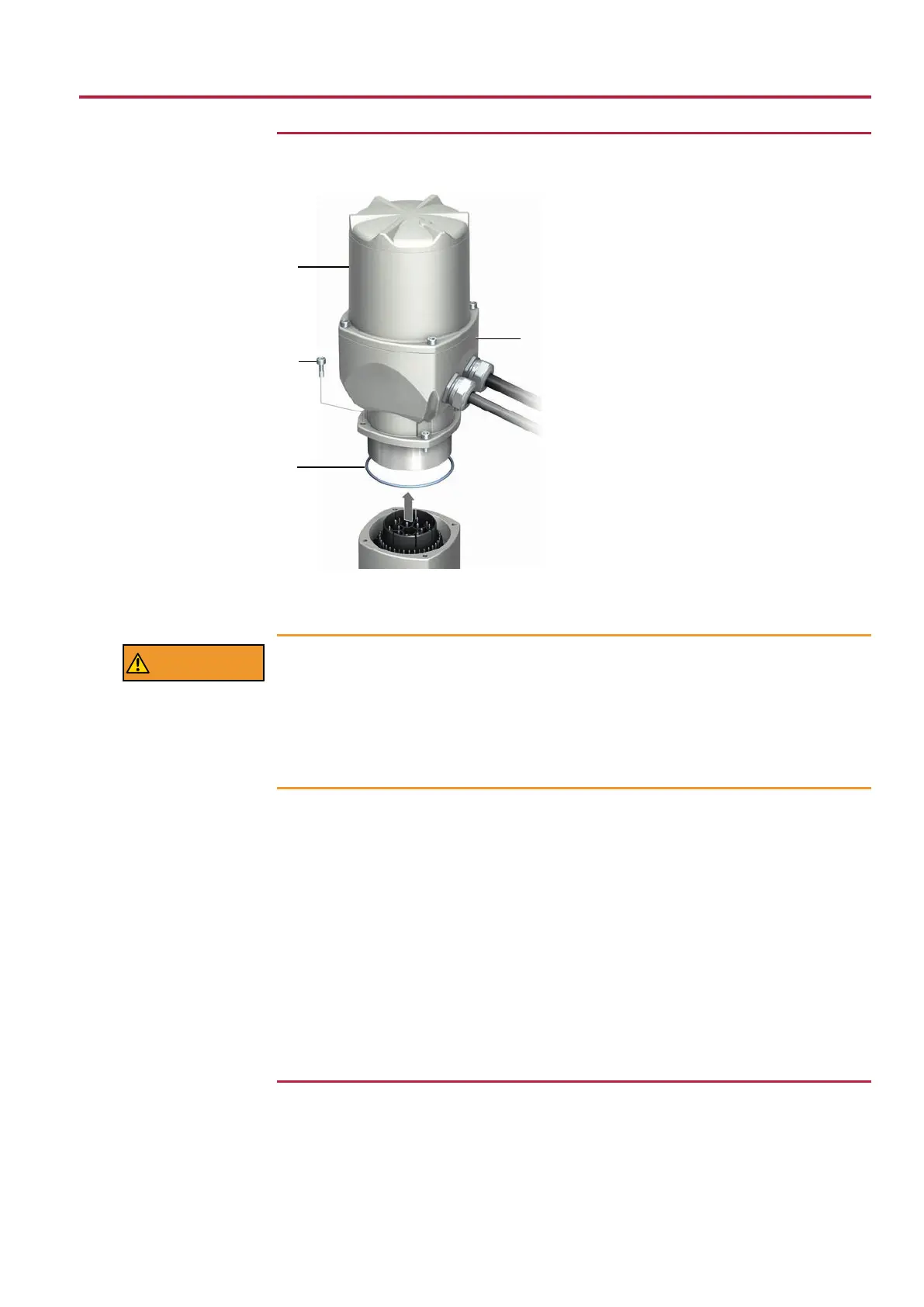

Figure38: KES Ex d electrical connection

[1] Cover [2] Screws for housing

[3] O-ring [4] Plug-in frame (KES)

WARNING

Ignition of potentially explosive atmospheres caused by sparks

Risk of death or serious injury

à Before opening the flameproof enclosure, ensure absence of gas and voltage.

à Handle cover and housing parts with care.

à Joint surfaces must not be damaged or soiled in any way.

à Do not jam cover during fitting.

Removing the plug 1. Loosen the screws [2].

2. Remove electrical connection.

ð For electrical connections of KES type, cover [1] and connection frame [4] re-

main assembled.

3. Seal open plug/socket connection, e.g. using AUMA protection cover and parking

frame.

Fitting the plug 4. Clean sealing faces of plug/socket connector and housing.

5. Preserve joint surfaces with an acid-free corrosion protection agent.

6. Check whether O-ring [3] is in good condition, replace if damaged.

7. Apply a thin film of non-acidic grease (e.g. petroleum jelly) to the O-ring and insert

it correctly.

8. Replace electrical connection and fasten screws evenly crosswise.

13.3

Maintenance

Manual operation During maintenance, the mechanical parts of the handwheel activation, in particular

motor coupling and retaining spring, must be checked. Replace the parts in case of

visible wear.

Lubrication • In the factory, the gear housing is filled with grease.

• Additional lubrication of the gear housing is not required during operation.

• Grease change is performed during maintenance

Loading...

Loading...