Corrective actions

39

12

Corrective actions

12.1

Faults during operation/commissioning

Table20: Faults during operation and commissioning

Fault Description/cause Remedy

Mechanical position indicator cannot

be set.

Reduction gearing is not suitable for actuator

swing angle.

Set gear stage of the reduction gearing.

In spite of correct setting of mechani-

cal limit switching, actuator operates

into the valve or actuator end position.

The overrun was not considered when setting the

limit switches.

The overrun is generated by the inertia of both the

actuator and the valve and the delay time of the

actuator controls.

• Determine overrun: Overrun = travel covered

from switching off until complete standstill.

• Set limit switches again considering the over-

run. (Turn handwheel back by the amount of

the overrun)

No value can be measured at measur-

ing points of the RWG.

Current loop across RWG is open.

(Position feedback 0/4 – 20 mA is only possible if

the current loop is closed across the RWG.)

• Connect link across RWG to XK (terminals

23/24)

• Connect external load to XK, e.g. remote indi-

cation.

• Observe max. load R

B

.

Measuring range 0/4 – 20mA or maxi-

mum value 20mA at position transmit-

ter cannot be set or supplies an incor-

rect value.

Reduction gearing is not suitable for actuator

swing angle.

Set gear stage of the reduction gearing.

The measuring range 0/4 – 20mA at

EWG position transmitter cannot be

set.

The LED on the EWG either flashes in setting

mode a) single flash or b) triple flash:

a) EWG is not calibrated.

b) Magnet positions of EWG are not aligned.

Request AUMA Service.

Limit and/or torque switches do not

trip.

Switches are defective or switch setting is incor-

rect.

Check setting, if required, reset end positions.

Refer to Switch check [}39], replace switches if

required.

Handwheel rotates on the shaft with-

out transmitting torque.

Actuator in version with overload protection for

manual operation: Shear pin rupture due to exces-

sive torque at handwheel.

Dismount handwheel. Replace overload protection

and remount handwheel.

Switch check

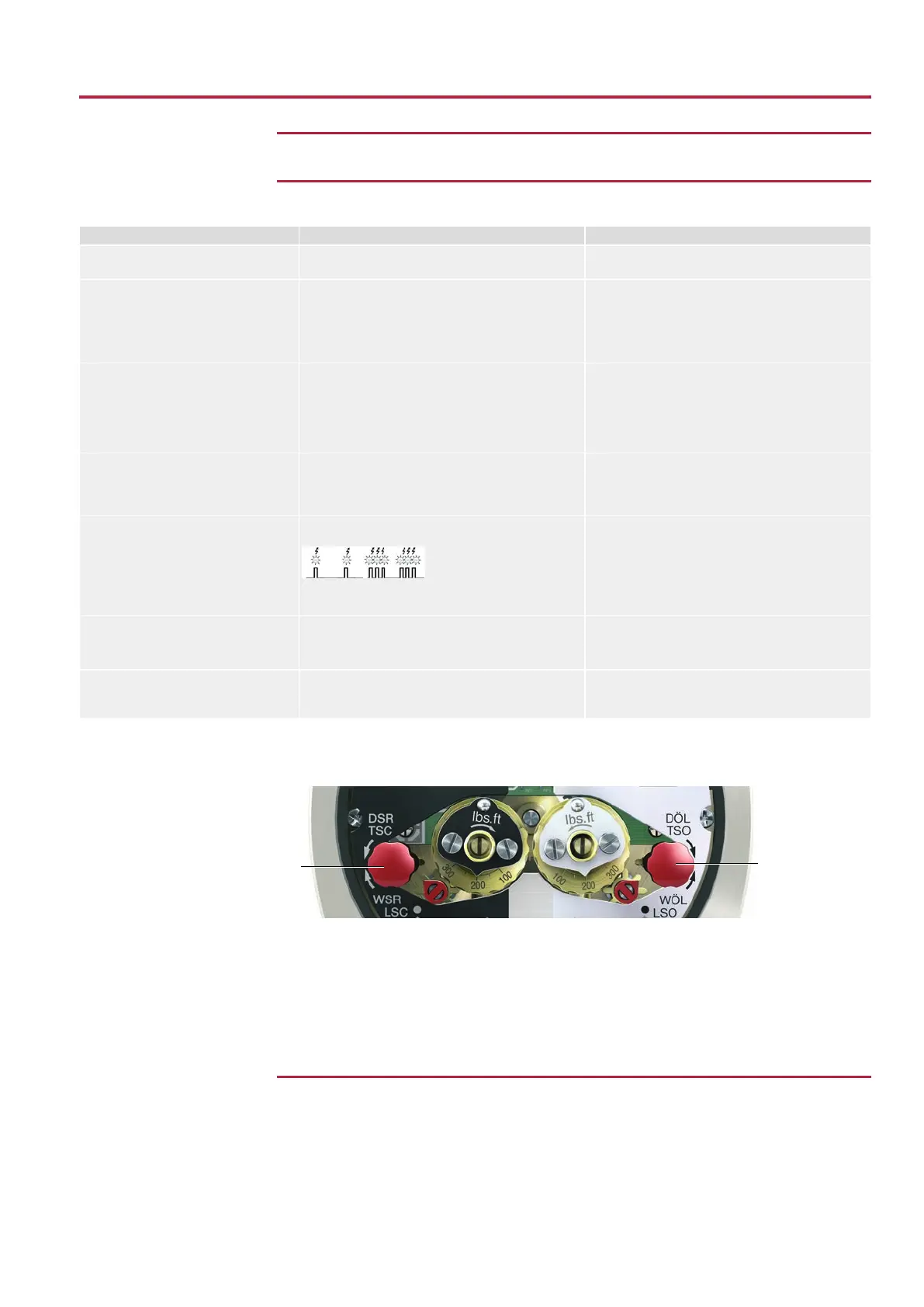

The red test buttons [1] and [2] are used for manual operation of the switches:

Figure37: Test buttons

1. Turn test button [1] in direction of the TSC arrow: Torque switch CLOSED trips.

2. Turn test button [2] in direction of the TSO arrow: Torque switch OPEN trips.

If the actuator is equipped with DUO limit switches (option), the intermediate position

switches (LSA and LSB) will be operated at the same time as the torque switches.

1. Turn test button [1] in direction of the LSC arrow: Limit switch CLOSED trips.

2. Turn test button [2] in direction of the LSO arrow: Limit switch OPEN trips.

12.2

Motor protection (thermal monitoring)

Thermal switches are provided in the motor winding to monitor the motor winding tem-

perature. The thermal switches trip as soon as the max. permissible winding tempera-

ture has been reached.

Possible causes Overload, running time exceeded, max. number of starts exceeded, ambient tempera-

ture exceeded.

Loading...

Loading...