46

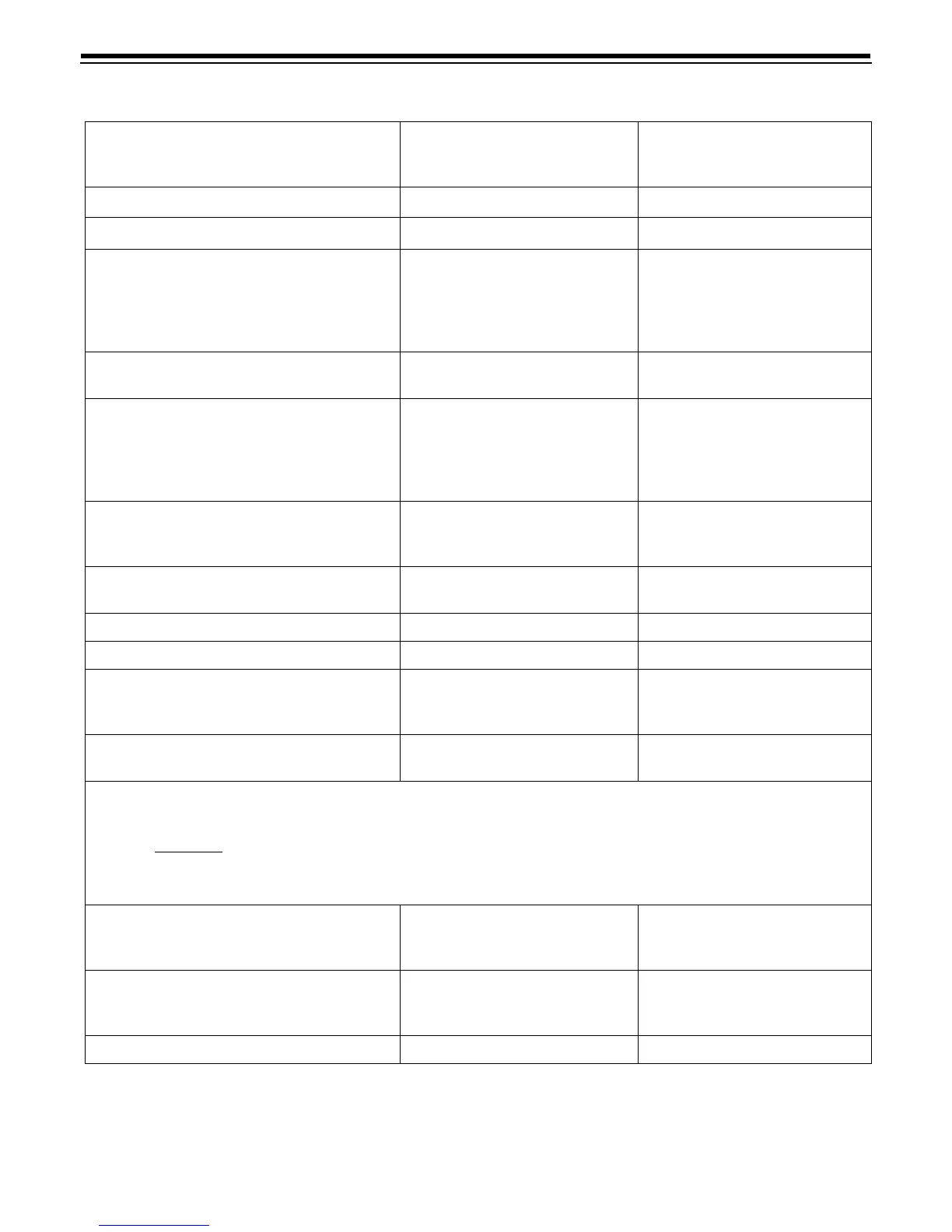

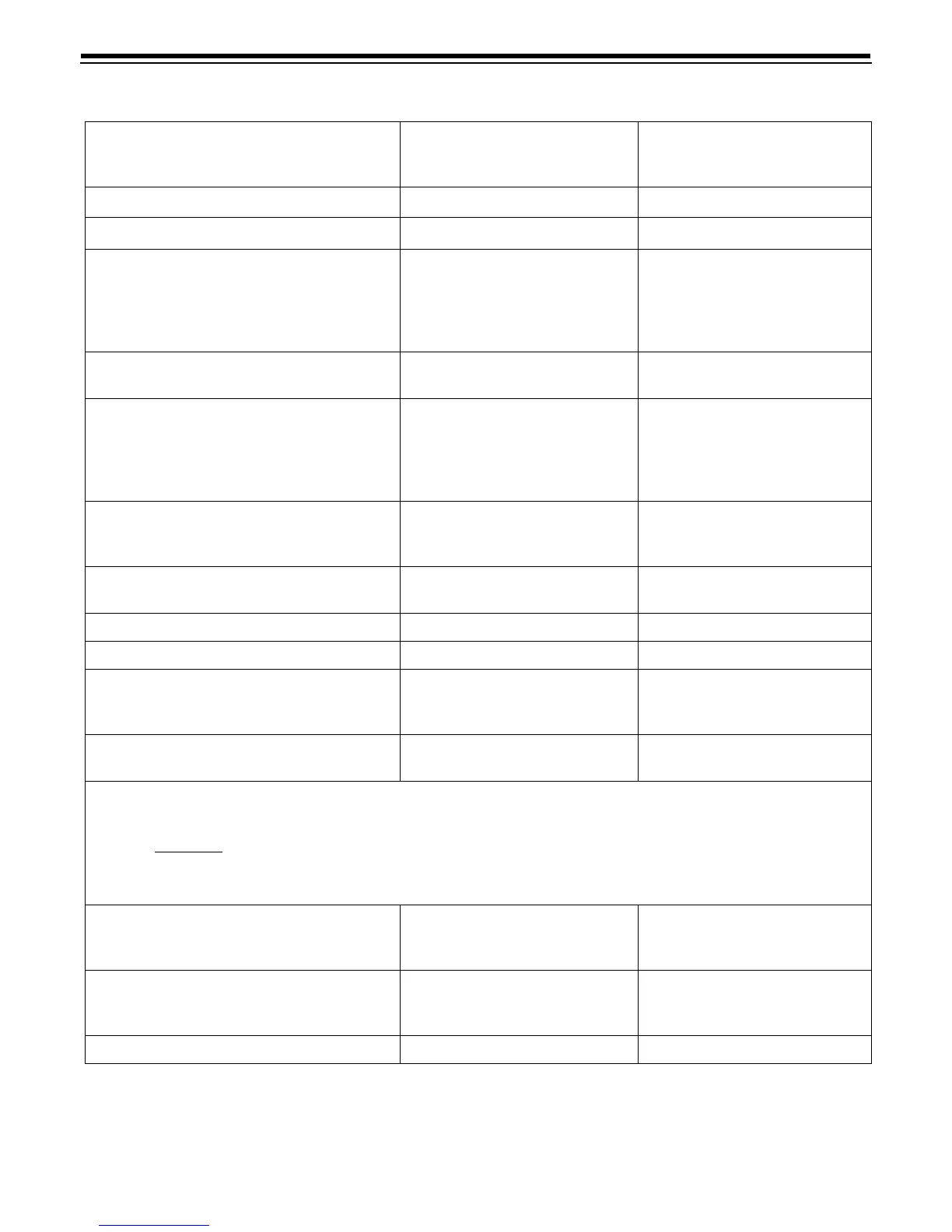

7.1.1 Twin Alternating Control Set-Up

Task

962M Main Control Position

Tank 1

962S Secondary Control

Position

Tank 2

1. Open manual bypass valve

2. Close manual inlet and outlet valves

3. Mount 962M main and 962S

secondary controls [962M and 962S

controls must be in the midpoint of the

SERVICE position before inserting

camshaft]

SERVICE SERVICE

4. Connect 12VAC power supply to 962M

control

SERVICE SERVICE

5. Program the 962M main control. (See

Table IIC for programming parameters.)

[LED will show ERR4 message

indicating controls require

programming]

SERVICE SERVICE

6. Exit programming mode. Depress up

and down buttons for 3 seconds or

wait 30 seconds

SERVICE SERVICE

7. Disconnect 12VAC power supply from

962M control

SERVICE SERVICE

8. Manually rotate camshafts to REFILL REFILL REFILL

9. Connect external cam switches REFILL REFILL

10. Connect 962M main and 962S

secondary controls with

factory-installed 4-pin connector.

REFILL REFILL

11. Reconnect 12VAC power supply and

optional battery backup to the 962M

REFILL REFILL

12. Observe controls for proper operation.

[Tank 1 control will rotate to the

STANDBY position followed by Tank 2]

STANDBY REFILL

13. Observe controls for proper operation.

[962M will remain in STANDBY. 962S

will rotate to SERVICE]

STANDBY SERVICE

14. System is now ready for operation STANDBY SERVICE

When connecting the optional battery backup,

the black wire

should be connected first!

Connecting the red wire first could result in serious

damage to the circuit board.

Important:

Con-

Loading...

Loading...